Method for recovering solvent from ammoximation reaction liquid

A technology for ammoximation reaction and solvent recovery, which is applied in oxime preparation, organic chemistry, etc., can solve problems such as environmental hazards, high energy consumption, and increased production cost of cyclohexanone oxime, and achieve the effect of saving production costs and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

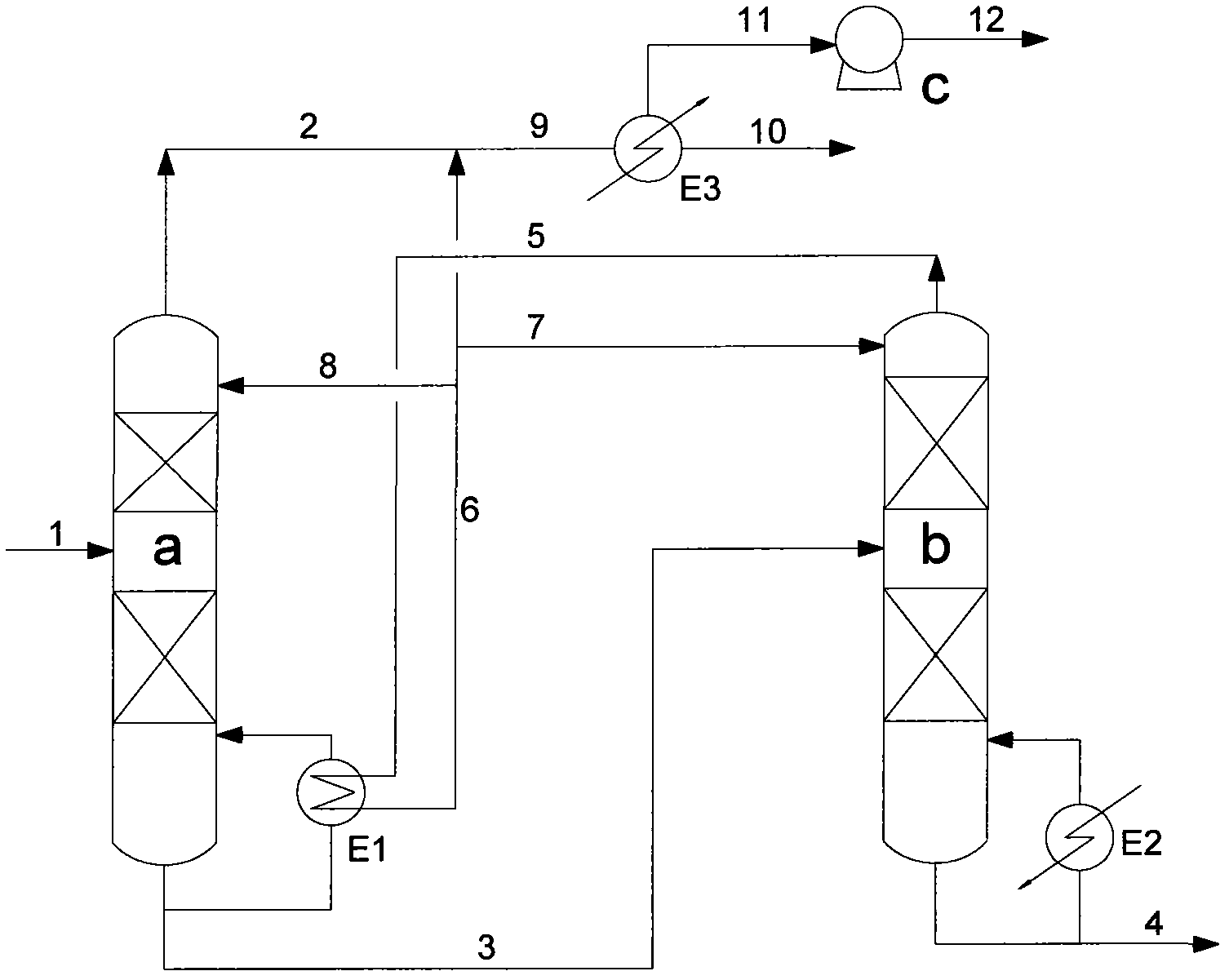

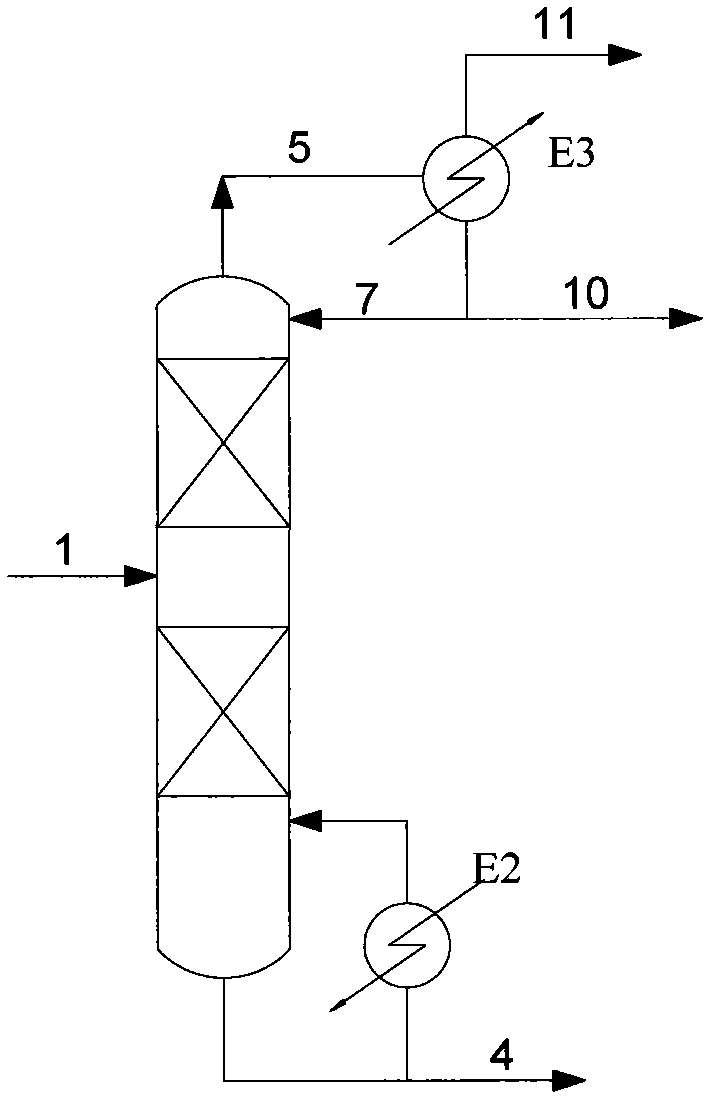

[0039] according to figure 1 The flow scheme shown is implemented. Among them, the inner diameter of the distillation towers a and b is 0.35 meters, with 8 meters of BX500 packing inside, equipped with reflux and feed distributors, reboilers E1 and E2 are vertical fixed tube-sheet heat exchangers, and the heat exchange area of E1 is 14 square meters The heat exchange area of E2 is 9 square meters, and the condenser E3 is a 2-tube fixed tube-sheet heat exchanger with a heat exchange area of 60 square meters.

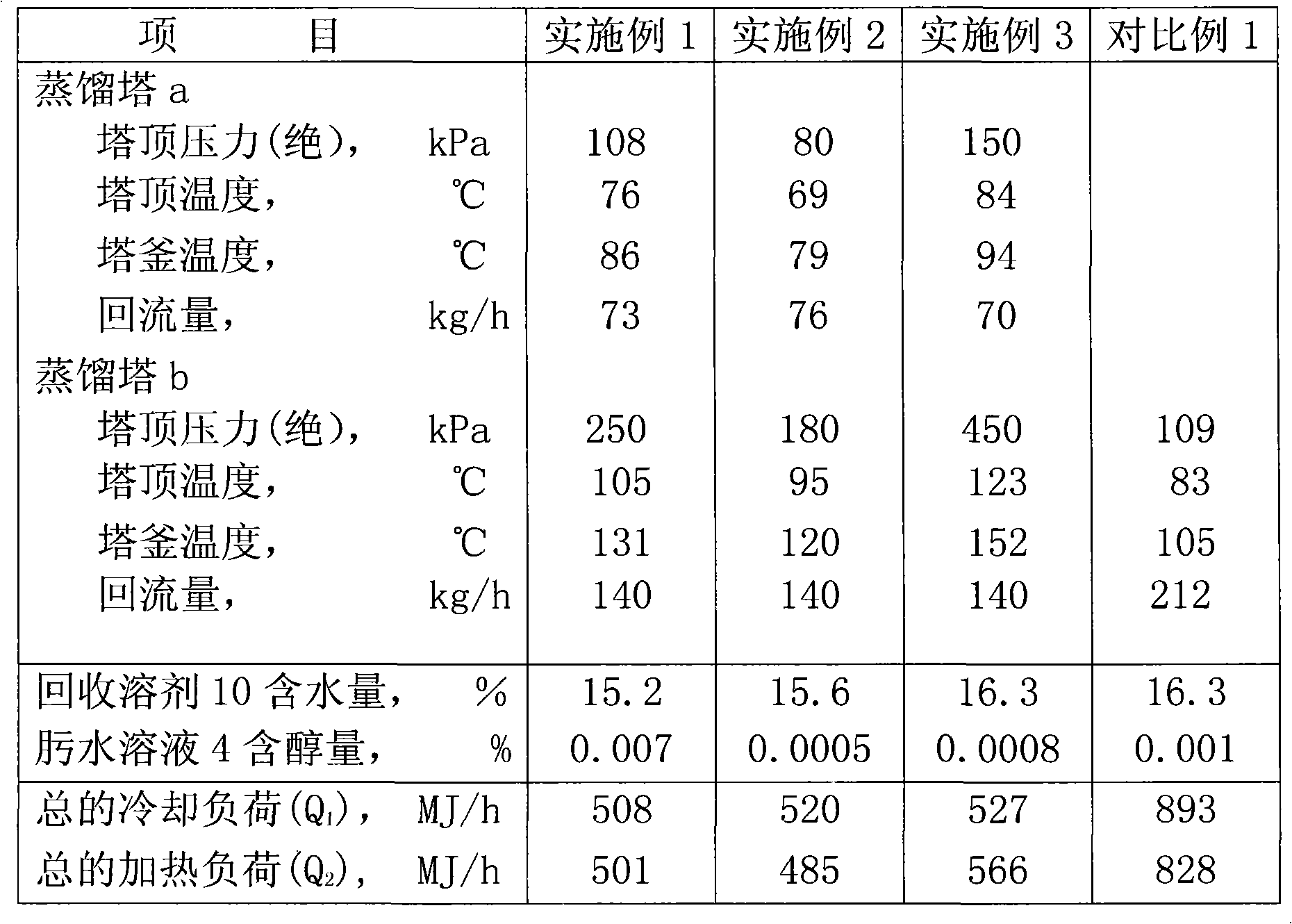

[0040] The ammoximation reaction solution containing 2.8% of ammonia, 20.2% of cyclohexanone oxime, 41.3% of tert-butanol, 35.6% of water, and 0.08% of cyclohexanone is continuously passed into distillation tower a at a flow rate of 1237 kg per hour, and distilled Tower a maintains natural normal pressure, the material in the tower kettle is pumped and sent to distillation tower b, reboiler E2 is fed with 1.0MPa water vapor, the operating pressure of distillation t...

Embodiment 2

[0043] Repeat Example 1, the difference is that distillation tower a adopts 80kPa negative pressure operation, distillation tower b adopts 180kPa operation, ammonia-containing non-condensable gas 11 is boosted to normal pressure with booster pump c, and its main operating conditions and results are summarized in Table 1.

Embodiment 3

[0045] Repeat Example 1, the difference is that the operating pressure of distillation tower a is 150kPa, and the operating pressure of distillation tower b is 450kPa, and its main operating conditions and results are summarized in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com