Preparation method of titanium silicalite molecular sieve catalyst with high performance

A titanium-silicon molecular sieve and catalyst technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of poor stability, low catalytic activity and high cost of titanium-silicon molecular sieve catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 0.2g of sodium hydroxide solid, dissolve it in 100ml of water, and make 0.05mol / L sodium hydroxide alkali treatment solution, add 10g of molecular sieve A1 to it, configure it into a mixed solution with a liquid-solid ratio of 10:1, and mix well Then transfer it to a stainless steel crystallization kettle lined with polytetrafluoroethylene, use hydrothermal crystallization method, treat at 100°C for 12h, filter and wash the product to neutrality, and then dry at 120°C for 4h to obtain a modified titanium-silicon molecular sieve catalyst B1.

Embodiment 2~6

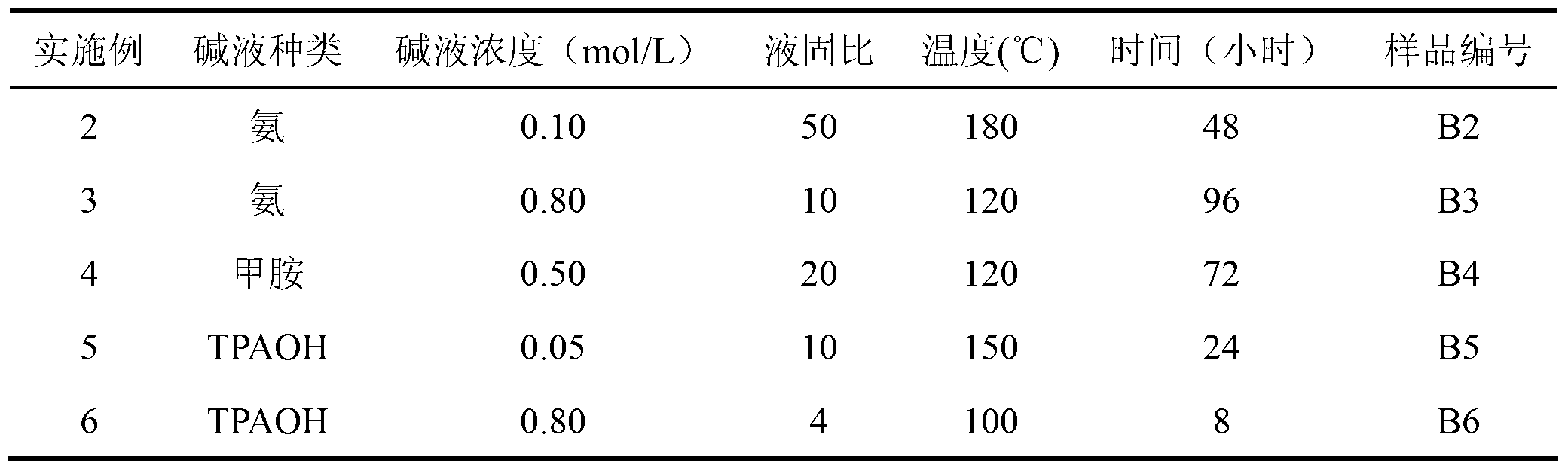

[0023] The preparation process is the same as in Example 1, and the specific raw material ratio and alkali treatment conditions are shown in Table 1. The sample numbers of the obtained alkali-treated modified titanium-silicon molecular sieve catalysts are B2-B6.

Embodiment 7

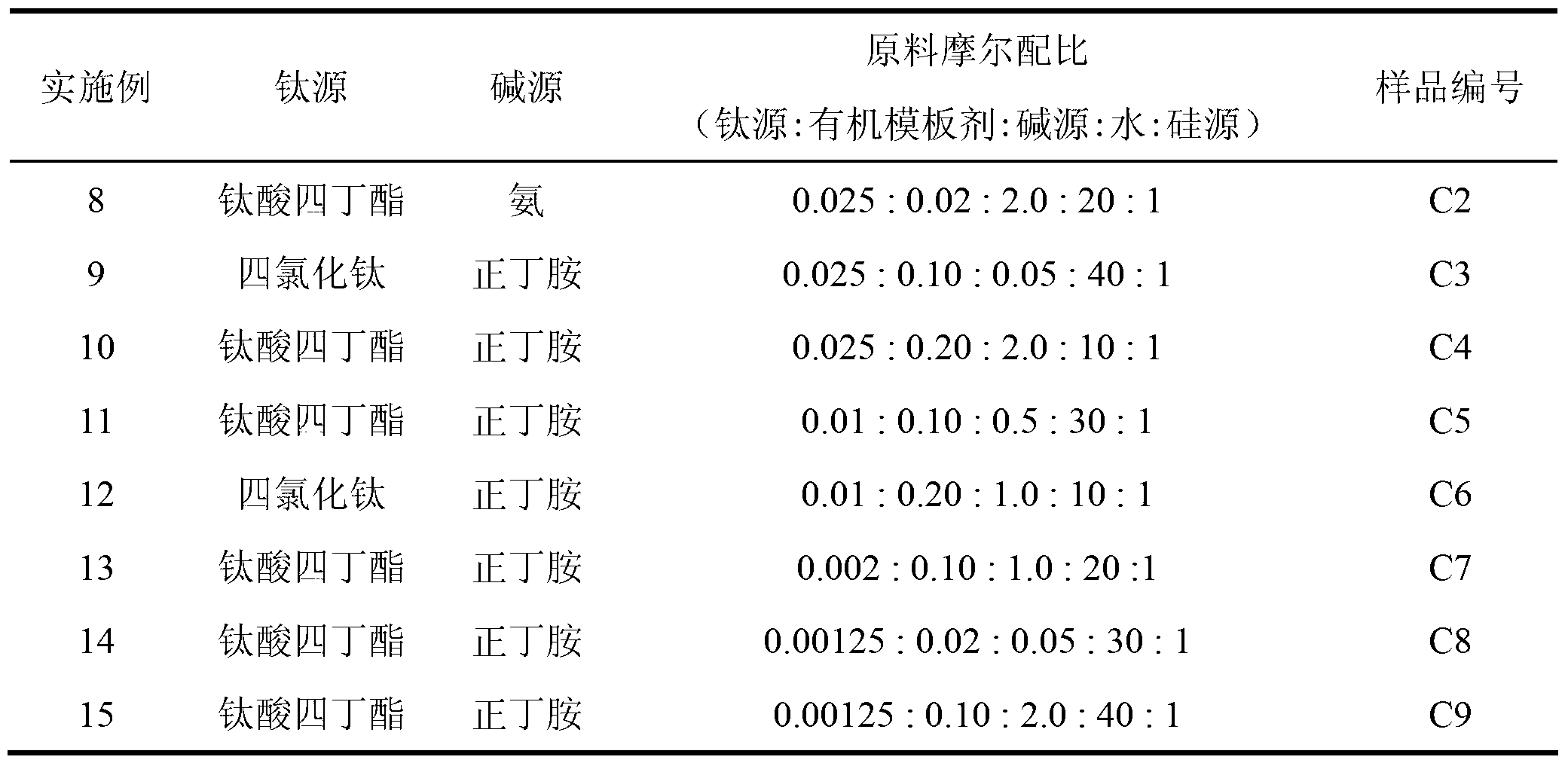

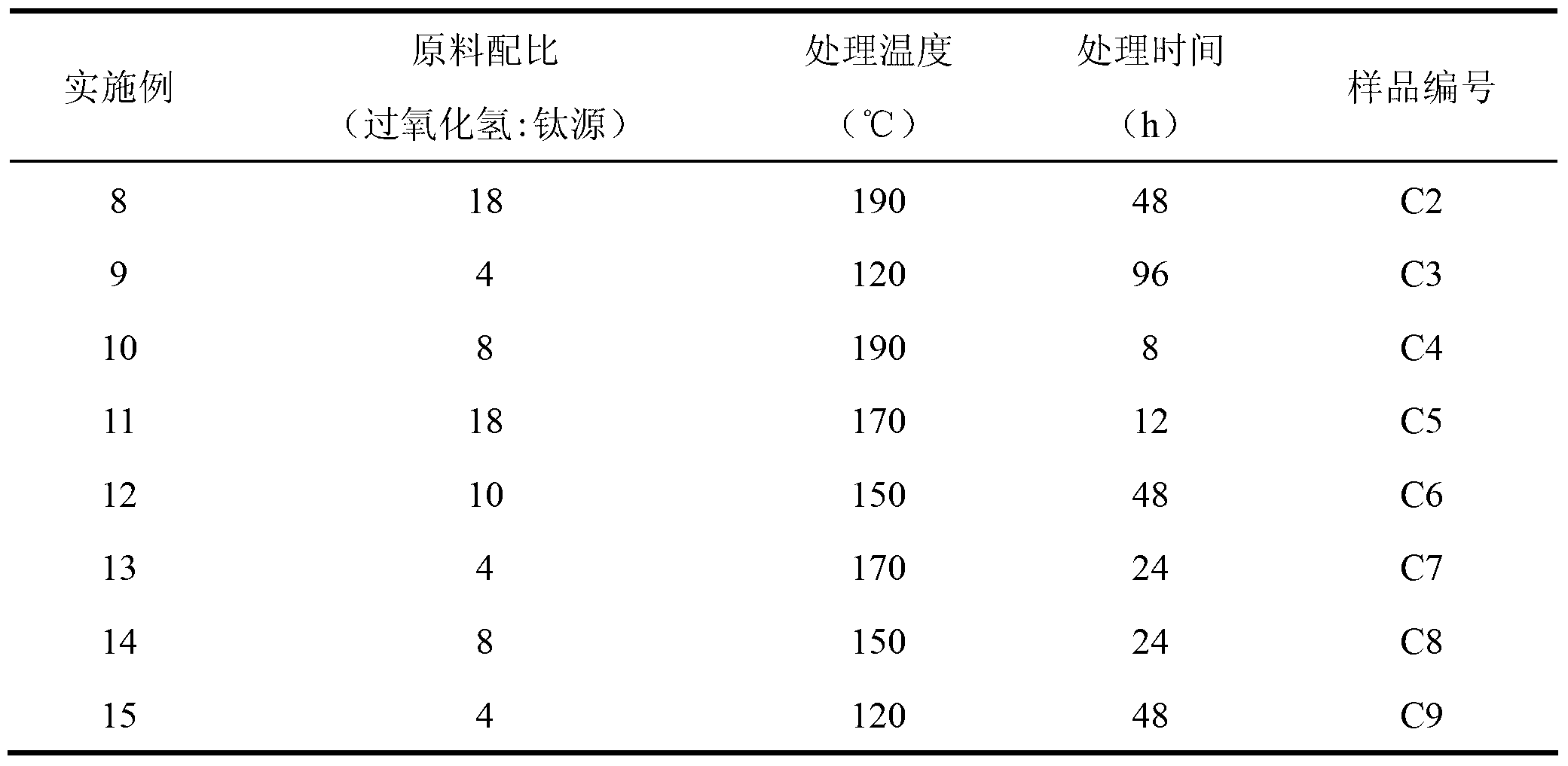

[0025] 1.1g tetrabutyl titanate (TBOT, TiO 2 wt%>23%), 1.71g tetrapropylammonium bromide (TPABr,>99wt%), 32.1g ammonia solution (NH 3 , 17wt%), 1.45g hydrogen peroxide solution (H 2 o 2 , 27wt%) and 88.4g of water were mixed evenly to form a yellow titanium modified solution, and then 10.0g of alkali-treated titanium-silicon molecular sieve B5 was added, and after stirring at room temperature, it was transferred to a stainless steel crystallization kettle lined with polytetrafluoroethylene to form The molar ratio is titanium source: organic template agent: alkali source: water: silicon dioxide=0.01:0.02:1.0:20:1, hydrogen peroxide: titanium source molar ratio=4:1 crystallization mother liquor, at 170 The secondary modification was carried out under the condition of dynamic stirring at ℃, and the treatment time was 24 hours. The product was filtered, washed, dried and calcined to obtain the modified titanium-silicon molecular sieve catalyst C1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com