All-silicon molecular sieve and synthetic method thereof

A technology of all-silicon molecular sieve and molecular sieve, which is applied in the direction of molecular sieve compounds, molecular sieve catalysts, polymorphic crystalline silicon with molecular sieve properties, etc. It can solve the problem of difficulty in increasing the solid content of molecular sieve synthesis crystallization products, low content of active ingredients in molecular sieves, and difficulty in collecting ethanol Reuse and other issues to achieve the effect of reducing synthesis costs, saving raw material costs, and reducing waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

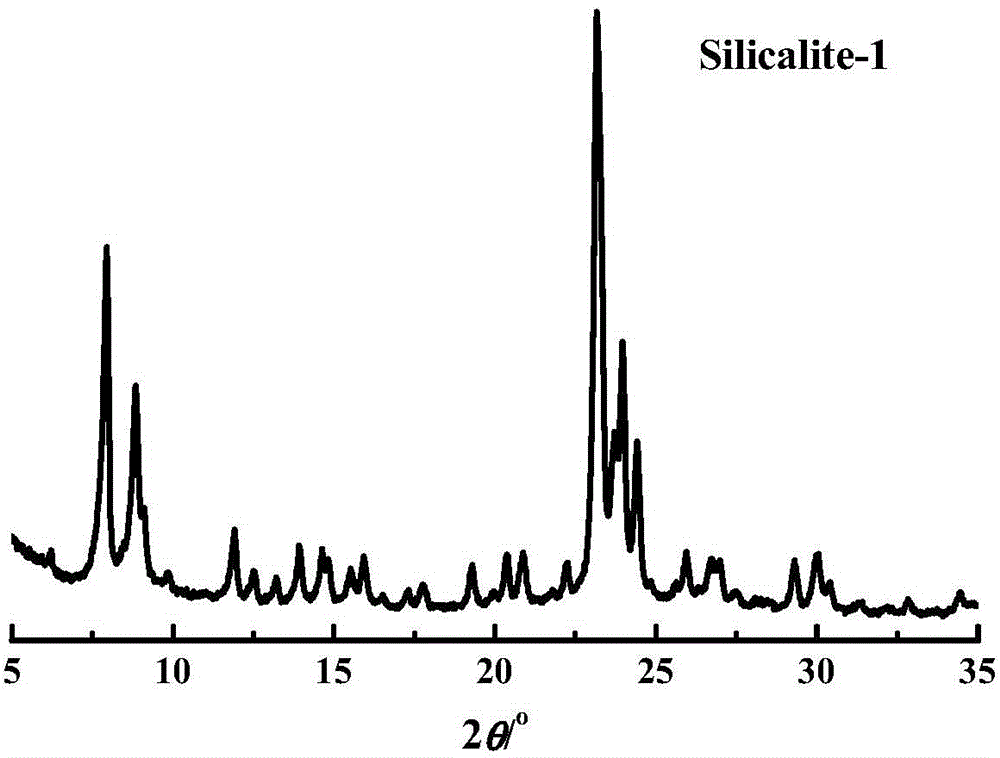

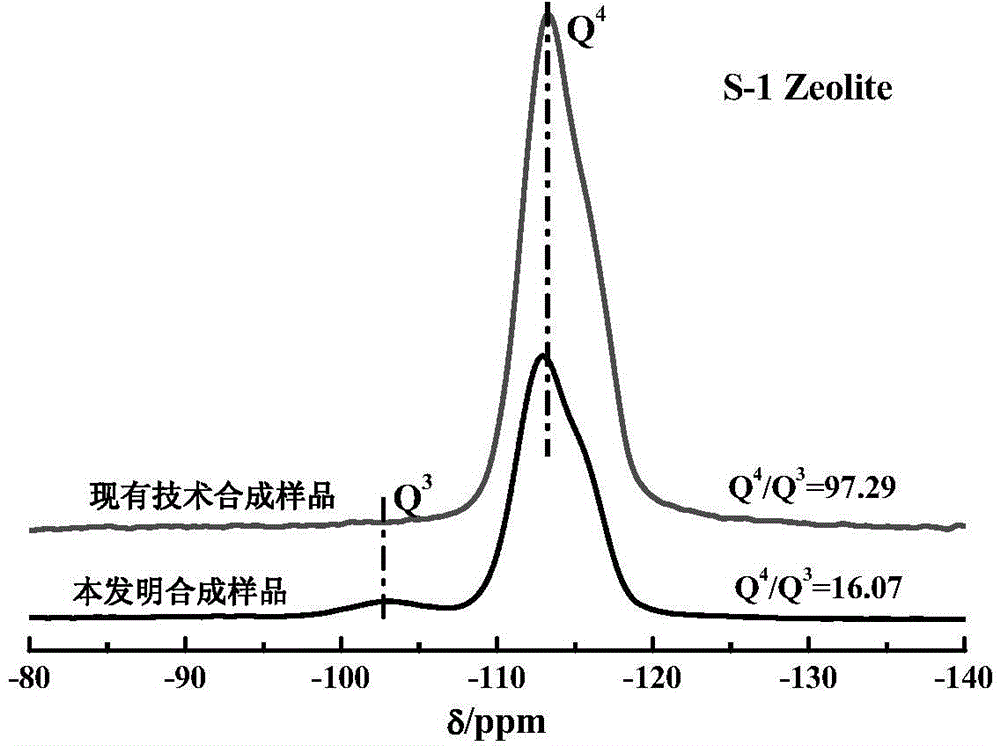

[0029] In one embodiment, the all-silicon molecular sieve is S-1 molecular sieve, and the template agent is tetrapropylammonium hydroxide or tetrapropylammonium hydroxide and tetrapropylammonium hydroxide selected from organic amines, tetrapropylammonium chloride, A mixture of one or more of tetrapropylammonium bromide.

[0030] In one embodiment, the all-silicon molecular sieve is S-2 molecular sieve, and the template agent is tetrabutylammonium hydroxide or tetrabutylammonium hydroxide and a mixture selected from organic amines, tetrabutylammonium chloride, tetrabutylammonium A mixture of one or more of ammonium bromide.

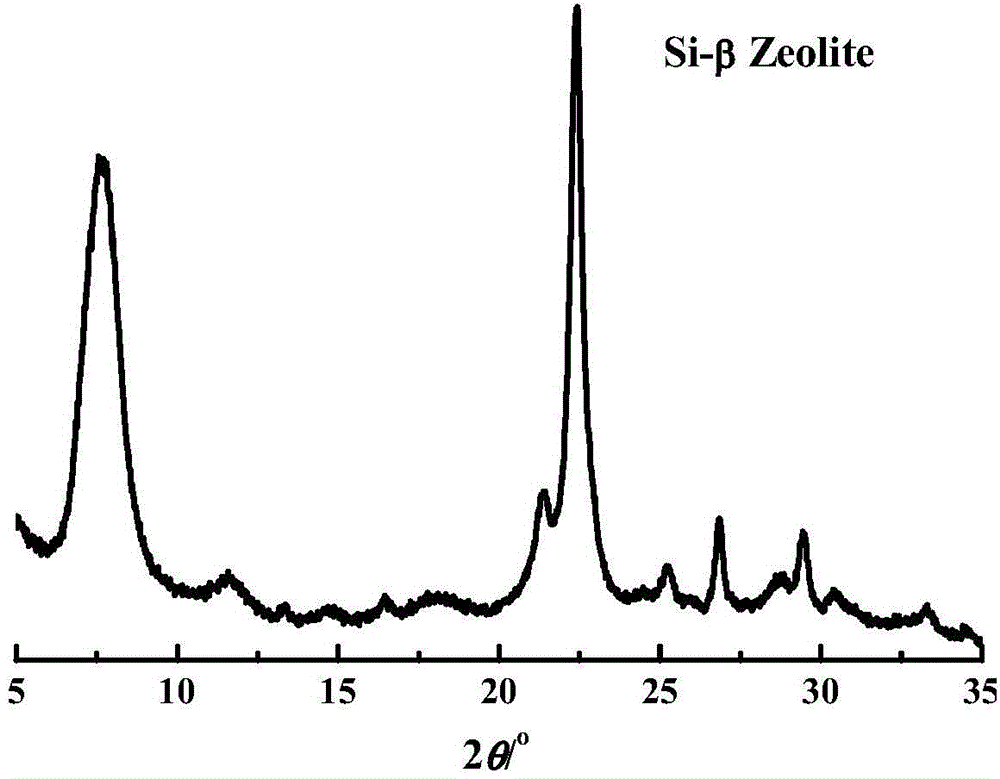

[0031] In one embodiment, the all-silicon molecular sieve is an all-silicon beta molecular sieve (all-silicon beta molecular sieve), and the template agent is tetraethylammonium hydroxide or tetraethylammonium hydroxide and tetraethyl bromide A mixture of one or more of ammonium chloride, tetraethylammonium chloride and organic amines.

[0032] In the me...

Embodiment 1

[0055] (1) Add 12.47g of tetrapropylammonium hydroxide aqueous solution with a concentration of 25.05% by weight, 20.8g of tetraethyl silicate, 0.26g of ammonia water with a concentration of 20% by weight and 33.85g of deionized water into a 500ml beaker in sequence , put into a magnetic stirrer with heating and stirring functions, stir at 80°C for 4 hours, replenish evaporated water at any time, and obtain an organic alkali hydrolyzate of silicon; wherein the content of monohydric alcohol does not exceed 10ppm;

[0056] (2) Cool the obtained organic alkali hydrolyzate of silicon to room temperature (26°C) under stirring, and then leave it to age at room temperature (26°C) for 12 hours to obtain an aged product;

[0057] (3) Under stirring, add 12g of white carbon black powder to the aging product, stir for 1 hour, transfer it to a closed stainless steel reaction kettle, and crystallize at a constant temperature of 165°C for 12 hours to obtain all-silicon S-1 Molecular sieve c...

Embodiment 2~6

[0061] Molecular sieves were prepared according to the method of Example 1, except that the ratio and preparation conditions were adjusted, and the conditions in step (4) were inconvenient. See Table 1 for the ratio and characterization results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Radial length | aaaaa | aaaaa |

| Benzene adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com