Nanometer all-silicon molecular sieve and its preparation method and use

An all-silicon molecular sieve and nanotechnology, applied in molecular sieve catalysts, lactam preparation, chemical instruments and methods, etc., can solve problems such as reducing the diffusion efficiency of reactants and products, and achieve regular morphology, good catalytic performance, and crystallinity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

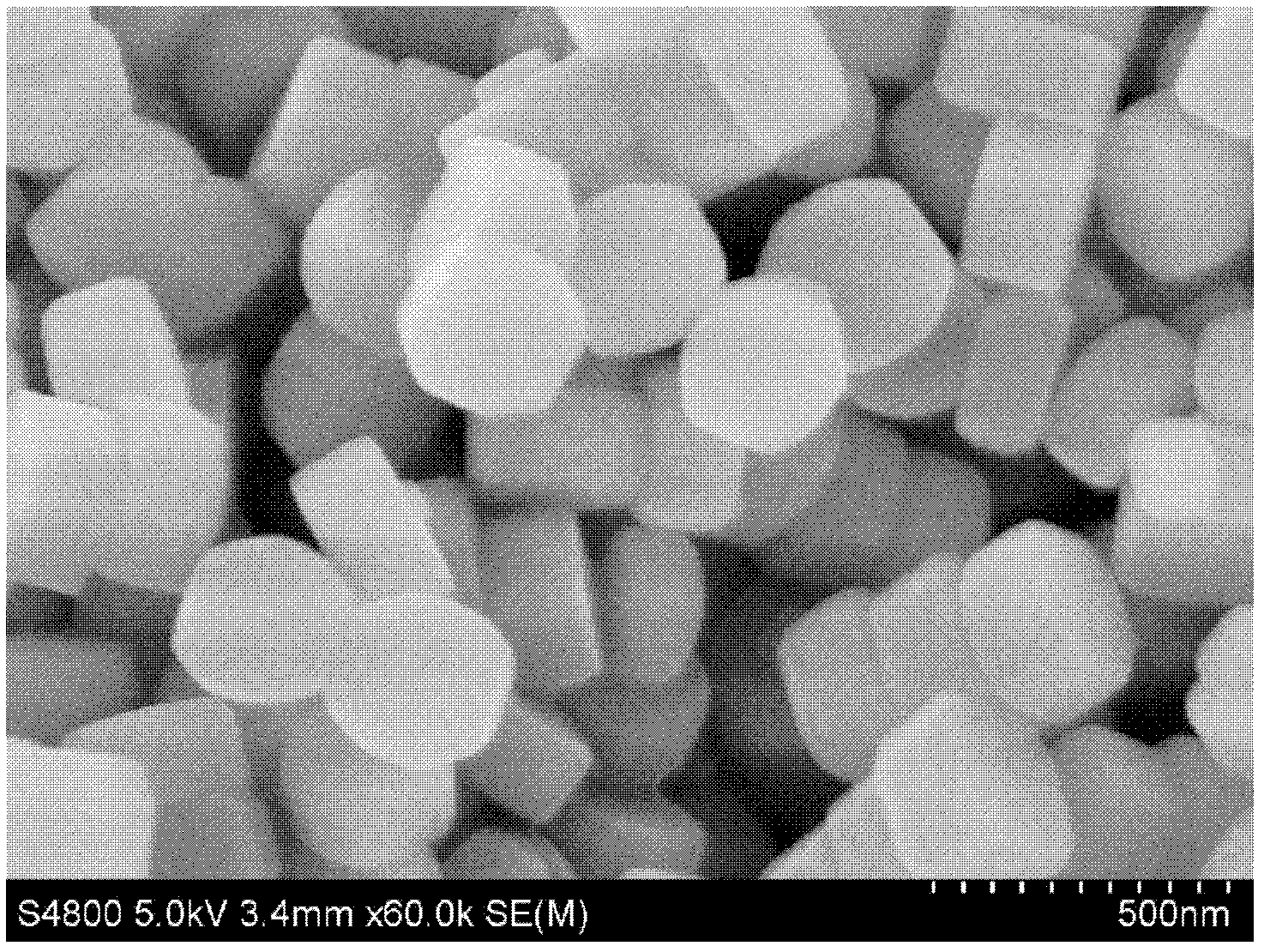

Embodiment 1

[0031] According to the reaction mixture SiO 2 :TPAOH:H 2O=1:0.3:16 molar ratio, weigh 30.65g of 0.83M TPAOH in a two-necked bottle, and mechanically stir in an ice bath. Weigh 18.39 g of tetraethyl silicate and slowly drop it into the above solution to form a clear solution. Add 0.06g of lysine (L-Lys) to this clear solution, stir well, and then dynamically age at 80°C for 24h. The above reaction mixture was transferred into an autoclave for hydrothermal crystallization at 170°C for 72h. Filtrate, wash, dry and roast according to conventional methods to obtain 4.5 g of molecular sieve products. The catalyst morphology and particle size were characterized by Hitachi S-4800 scanning electron microscope, and the samples were vacuum-sprayed with gold before SEM analysis and testing. Scanning electron micrographs show that the obtained molecular sieve is in the shape of a regular hexagonal prism with a side length of about 50 nm.

[0032] Molecular sieve catalyzed cyclohexano...

Embodiment 2

[0035] Change the CHO mass space velocity (WHSV) of catalyst performance evaluation in embodiment 1 to 4h -1 , Other methods are similar to Example 1, the reaction time is 100h, the conversion rate of cyclohexanone oxime is not less than 99%, and the selectivity of caprolactam is not less than 96%. , The deactivated catalyst is regenerated by roasting and recycled 10 times, and its performance remains basically unchanged.

Embodiment 3

[0037] According to the reaction mixture SiO 2 :TPAOH:H 2 O=1:0.3:16 molar ratio, weigh 30.65g of 0.83M TPAOH in a two-necked bottle, and mechanically stir in an ice bath. Weigh 18.39 g of tetraethyl silicate and slowly drop it into the above solution to form a clear solution. Add 0.24g of lysine (L-Lys) to this clear solution, stir well, and then dynamically age at 80°C for 24h. The above reaction mixture was transferred into an autoclave for hydrothermal crystallization at 170°C for 72h. Filtration, washing, drying and roasting according to the usual method to obtain 4.4g of molecular sieve product. Scanning electron micrographs show that the obtained molecular sieve is in the shape of a regular hexagonal prism with a side length of about 40nm.

[0038] The prepared molecular sieve catalyzed cyclohexanone oxime gas-phase Beckmann rearrangement performance evaluation similar to Example 1. The reaction time is 6 hours, the conversion rate of cyclohexanone oxime is 99.6%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com