Preparation method of porous hydrogel coating on surface of polypropylene patch

A surface-porous, polypropylene technology, applied in coatings and other directions, can solve the problems of reducing the mechanical strength of PP materials, reducing the mechanical properties of the body, and complicated preparation processes, so as to improve the hydrophilic properties, keep the mechanical properties from reducing, and promote The effect of abdominal wall repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

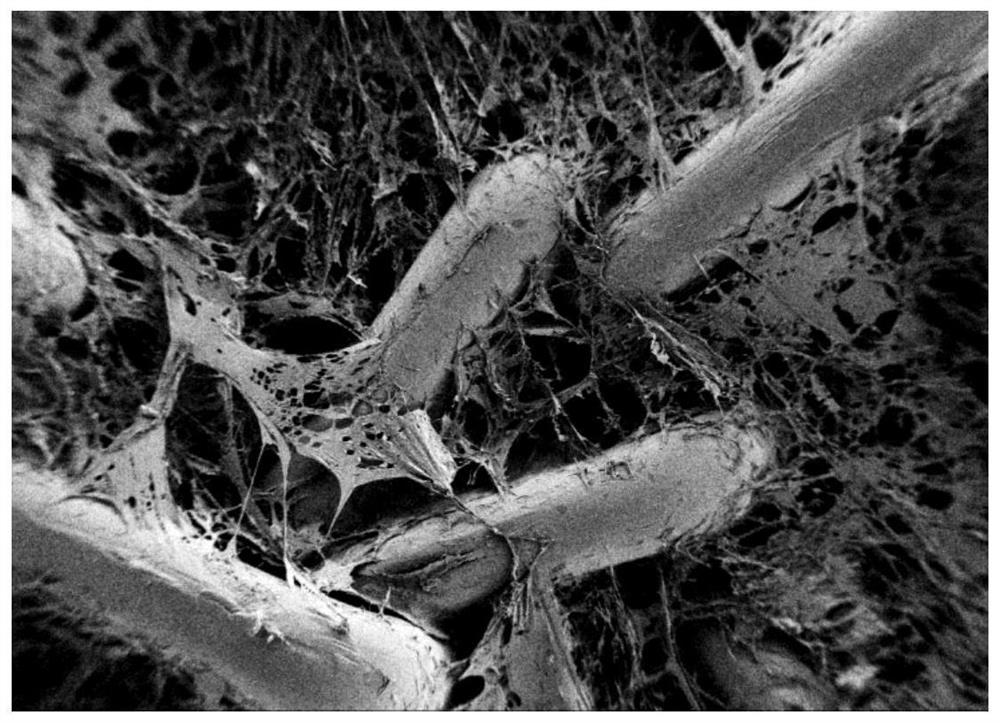

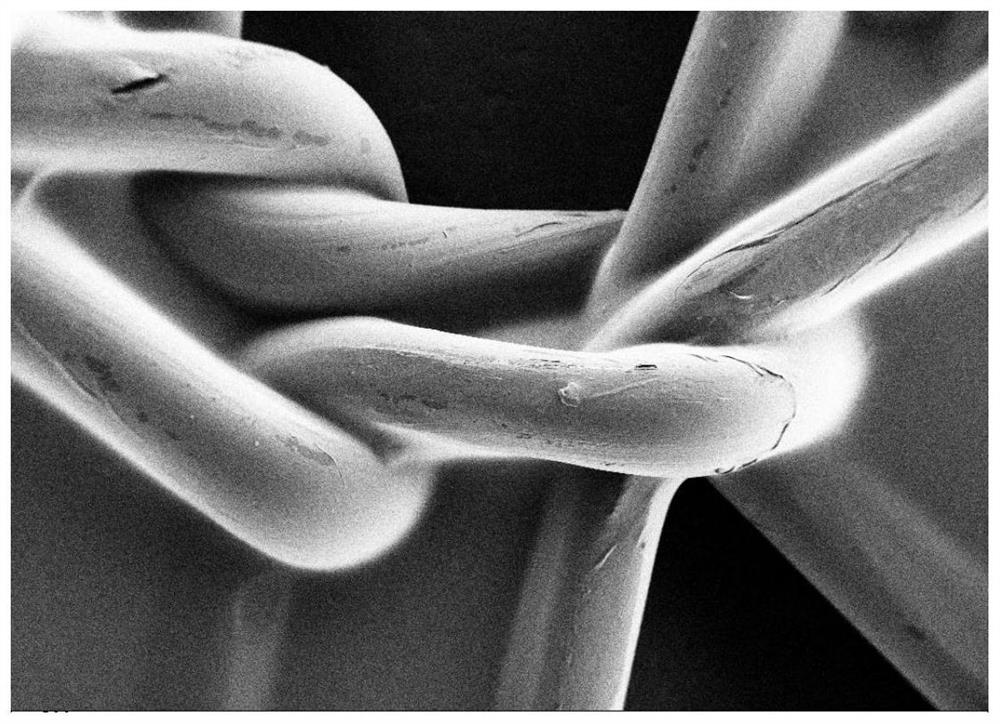

Image

Examples

Embodiment 1

[0030] (1) Place the PP material net in ethanol, stir and wash three times, 20mL each time, for three hours, and dry at 40°C for 24 hours;

[0031] (2) Add 4g of polyvinyl alcohol, with a degree of polymerization of 1750, into 40mL of deionized water, and stir to dissolve at 80°C;

[0032] (3) 0.8g sodium bicarbonate is dissolved in the polyvinyl alcohol solution in step (2), slowly stirred to dissolve;

[0033] (4) Add 0.027g of ferric chloride hexahydrate into 10mL of deionized water, and dissolve at room temperature to obtain a 0.01mol / L ferric chloride solution;

[0034] (5) Add 0.9 mL of ferric chloride hexahydrate solution in step (4) to the polyvinyl alcohol solution in step (3), and mix well;

[0035] (6) With the PP material net treated in step (1), its surface is coated with the mixed solution of polyvinyl alcohol and ferric chloride hexahydrate dissolved in step (5);

[0036] (7) Freeze the processed PP material web obtained in step (6) by non-directional freezing...

Embodiment 2

[0039] (1) Place the PP material net in dichloromethane, stir and wash three times, 20mL each time, for three hours, and dry at 25°C for 30 hours;

[0040] (2) Add 16g of polyvinyl alcohol, with a degree of polymerization of 1700, into 360mL of deionized water, and stir to dissolve at 80°C;

[0041] (3) 0.8g sodium bicarbonate is dissolved in the polyvinyl alcohol solution in step (2), slowly stirred to dissolve;

[0042] (4) Add 0.27g of ferric chloride hexahydrate into 10mL of deionized water, and dissolve at room temperature to obtain a 0.1mol / L ferric chloride solution;

[0043] (5) Add 0.9 mL of ferric chloride hexahydrate solution in step (4) to the polyvinyl alcohol solution in step (3), and mix well;

[0044] (6) With the PP material net treated in step (1), its surface is coated with the mixed solution of polyvinyl alcohol and ferric chloride hexahydrate dissolved in step (5);

[0045] (7) Freeze the treated PP material web obtained in step (6) by non-directional fr...

Embodiment 3

[0048] (1) Place the PP material net in dichloromethane, stir and wash three times, 20mL each time, for three hours, and dry at 30°C for 25 hours;

[0049] (2) Add 8g of polyvinyl alcohol, with a degree of polymerization of 1800, into 180mL of deionized water, and stir to dissolve at 80°C;

[0050] (3) 0.8g sodium bicarbonate is dissolved in the polyvinyl alcohol solution in step (2), slowly stirred to dissolve;

[0051] (4) 0.135g of ferric chloride hexahydrate was added to 10mL of deionized water, and dissolved at room temperature to obtain a 0.05mol / L ferric chloride solution;

[0052](5) Add 0.9 mL of ferric chloride hexahydrate solution in step (4) to the polyvinyl alcohol solution in step (3), and mix well;

[0053] (6) With the PP material net treated in step (1), its surface is coated with the mixed solution of polyvinyl alcohol and ferric chloride hexahydrate dissolved in step (5);

[0054] (7) Freeze the treated PP material web obtained in step (6) for 15 hours at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com