Spinneret

A technology of spraying and spraying boards, which is applied in the direction of spray head components, textiles and papermaking, which can solve the problems of inserting in a severe expansion shell, influence, and unfavorable accuracy of coordination, so as to improve automatic automatic automatic automatic accuracy The effect of sealing effect, small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

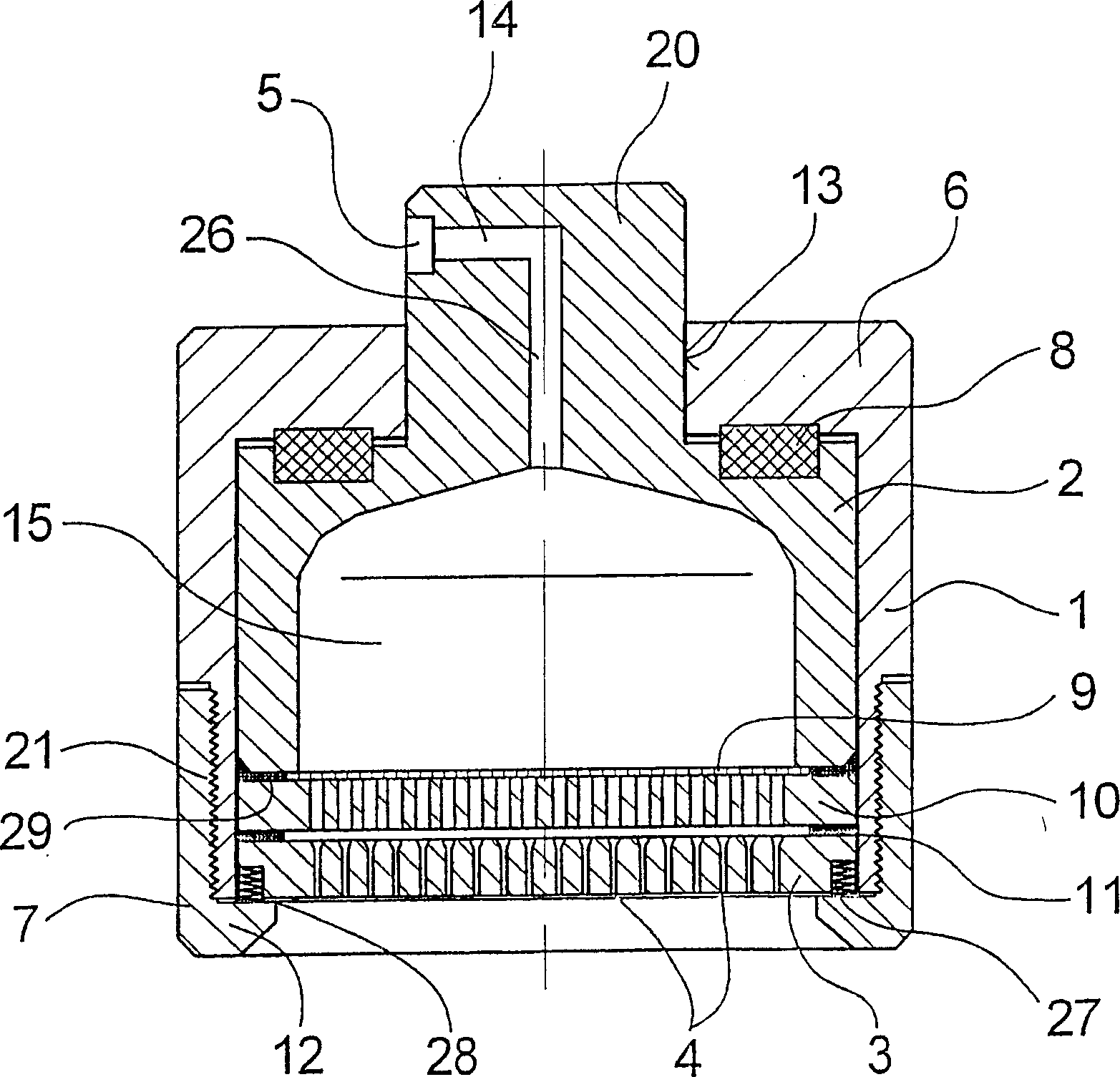

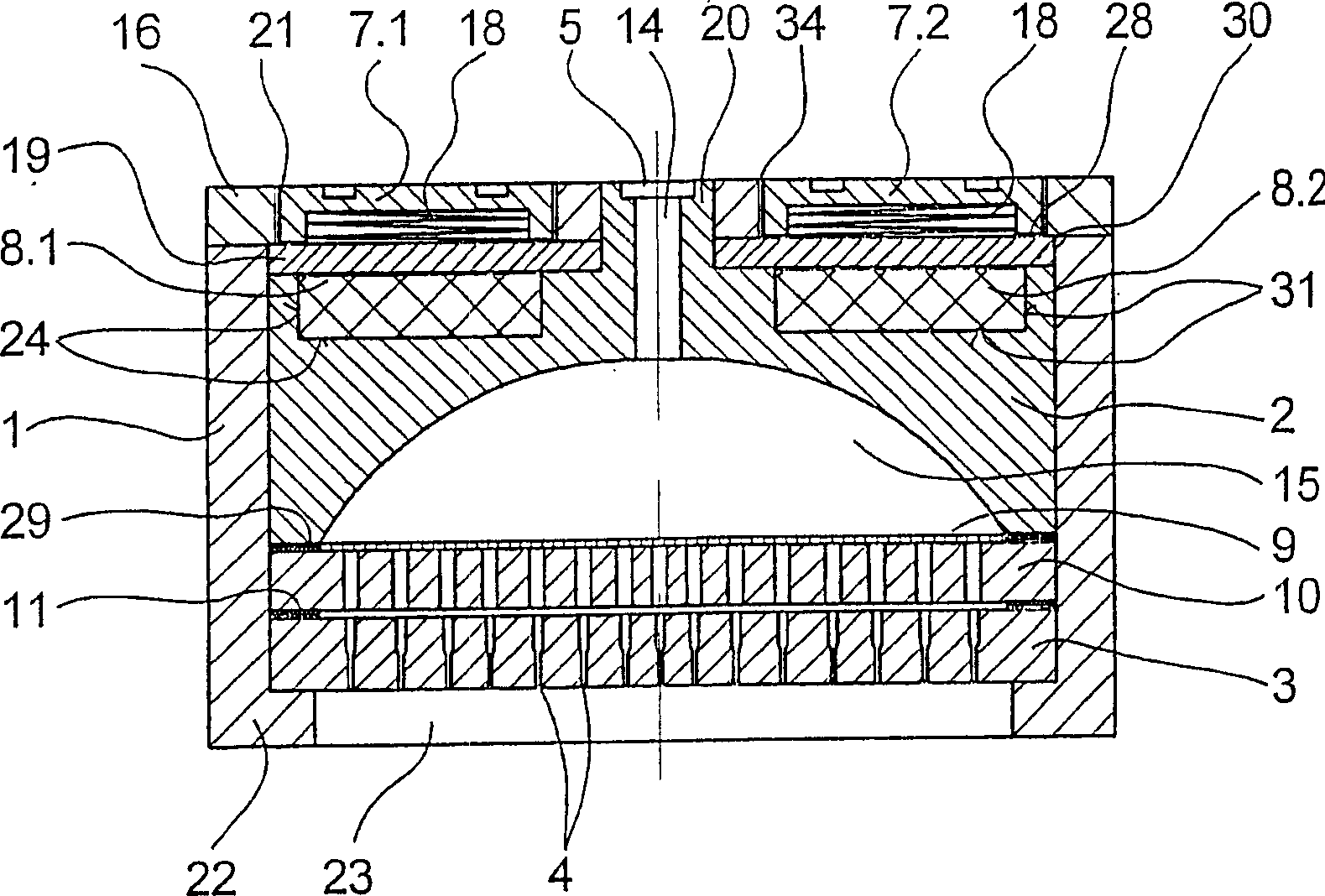

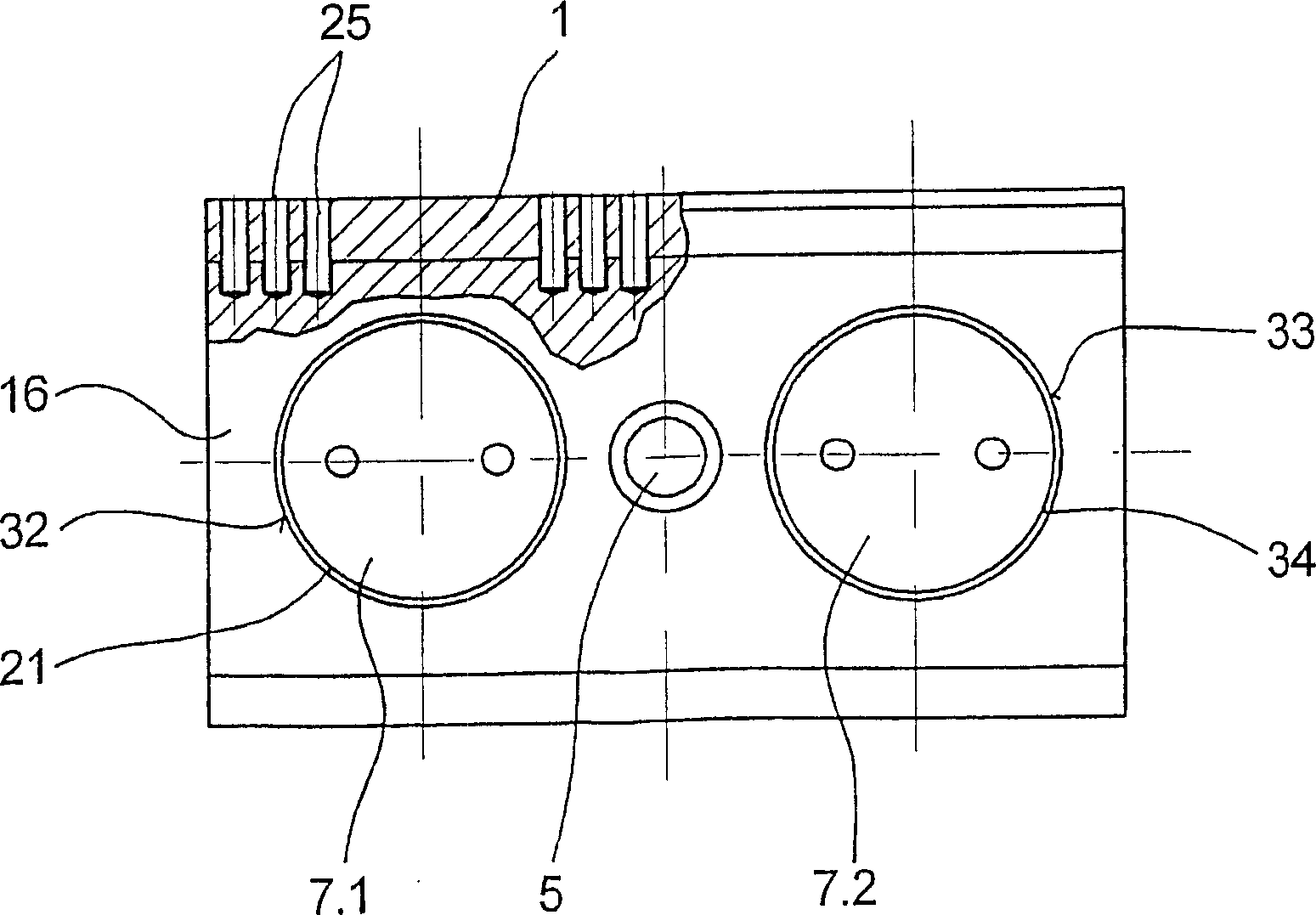

[0027] figure 1 shows a cross-sectional view of a first embodiment of a spinneret according to the invention. The spinneret has a cylindrical housing 1 which is delimited at the end by a base plate 6 in the upward direction. There is a hole 13 in the center of the bottom plate 6 . A boss 20 inserted into the inlet part 2 of the housing 1 protrudes through the opening 13 in the housing base 6 . An expansion body 8 in the form of an expansion ring is arranged between the inlet part 2 and the housing bottom 6 .

[0028] In this case, the inlet part 2 is supported on the housing base 6 via the annular expansion body 8 . The inlet part 2 has a melt inlet 5 on a boss 20 protruding outside the housing 1 , which communicates via an inlet channel 14 and a melt channel 26 with a distribution chamber 15 in the inlet part 2 . A filter assembly 9 , a perforated plate 10 and a spinneret 3 are connected to the end faces of the inlet part 2 in the housing 1 . An outer circumferential sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com