Dissolved air type spinneret

A technology of spinneret and dissolved air, which is applied in filament/thread forming, textile and papermaking, fiber treatment, etc. It can solve the problems of affecting the appearance of the product, the yarn is easy to be fluffy, and the thread elasticity is poor, so as to achieve water absorption Good, easy to twist, high microscopic surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

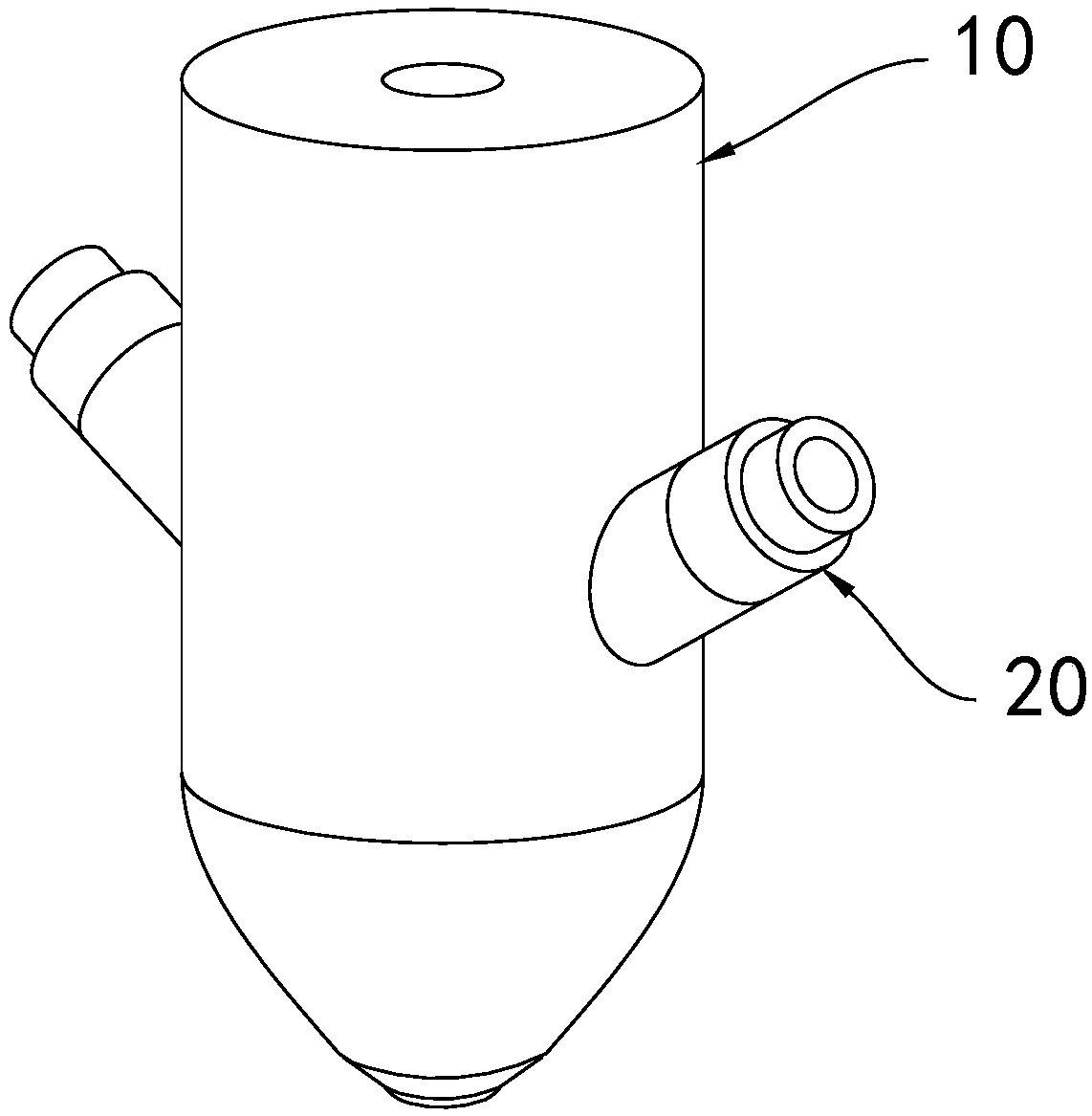

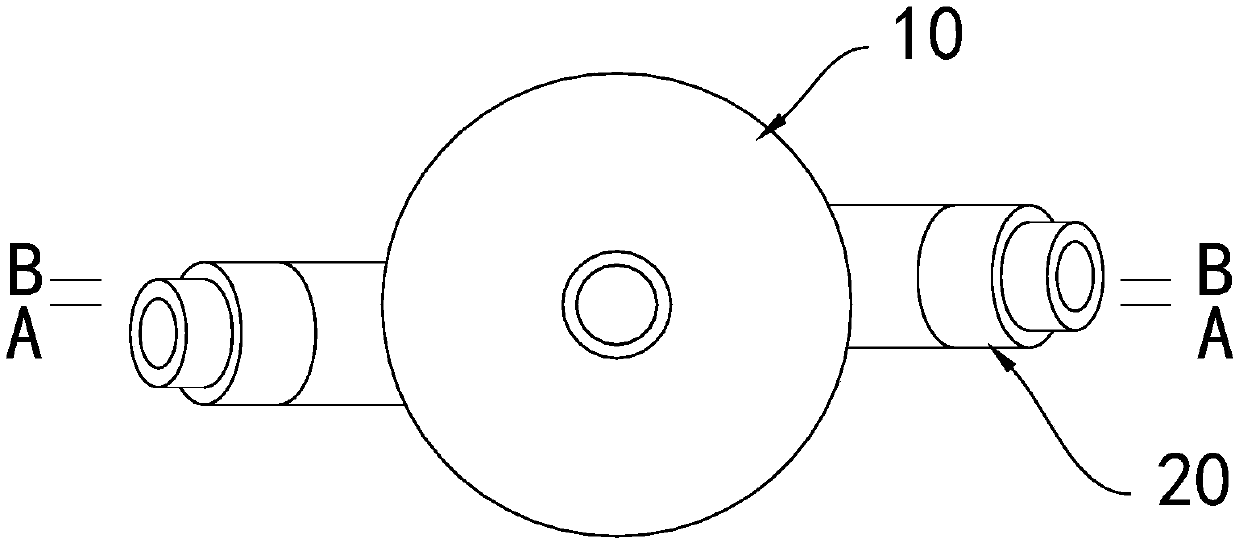

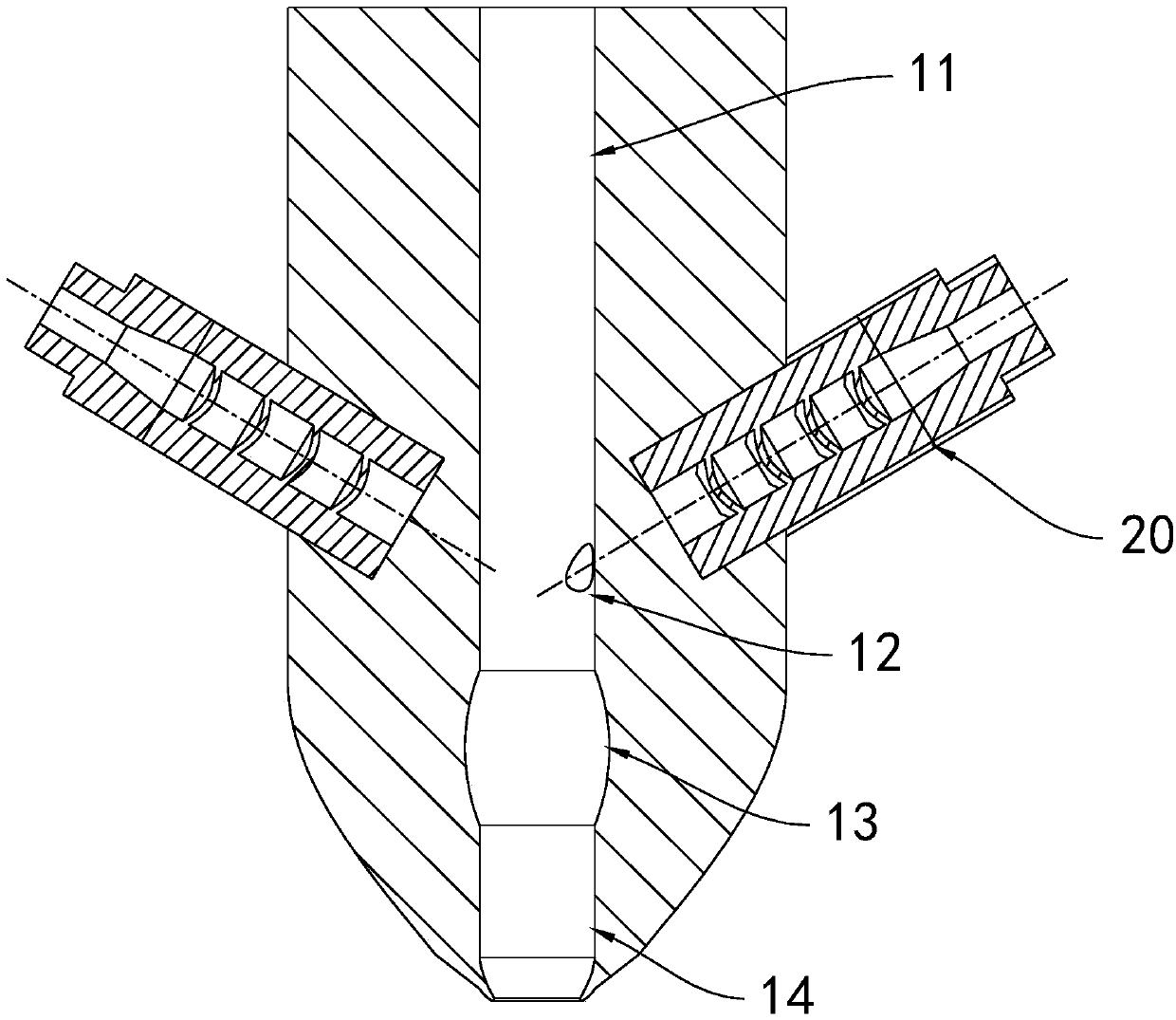

[0021] Embodiment: Dissolved air type spinneret, comprises main body 10, and main body 10 comprises feed section 11, air inlet section 12, slow flow section 13 and spinneret section 14 that are arranged in sequence; Described air inlet section 12 and An air pipe 20 is connected; the inner diameter of the slow flow section 13 is larger than the air inlet section 12 and the spinneret section 14 .

[0022] The trachea 20 is arranged tangentially along the main body 10 .

[0023] The air pipe 20 is provided with a non-return section at the connection with the main body 10, the non-return section includes a plurality of stop ring pieces 21 arranged axially along the air pipe 20, the stop ring pieces 21 are conical, and the stop ring The inclination direction of the generatrices of the sheet 21 is the same as the airflow direction.

[0024] The axis of the air pipe 20 forms an acute angle with the axis of the main body 10 , and the direction of the air pipe 20 is the same as the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com