Core-spun yarn

A technology of cored wire and core material, which is applied in the field of refined steel, can solve the problems of inability to melt quickly, fail to meet the needs of the industry, and cannot fully exert the role of the core material inoculant, so as to reduce the melting time and ensure the strength and toughness Effect

Inactive Publication Date: 2015-03-18

JIANGYIN YURUI METALLURGICAL FURNACE CHARGE

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current cored wire is covered with steel sheet for inoculation with flow. However, due to the high melting point of steel, it cannot be melted quickly during the inoculation process, and the mixing of core material and molten iron is not uniform, and the core material cannot be fully utilized. The role of the inoculant, so the treated steel can not meet the requirements, can not meet the needs of industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

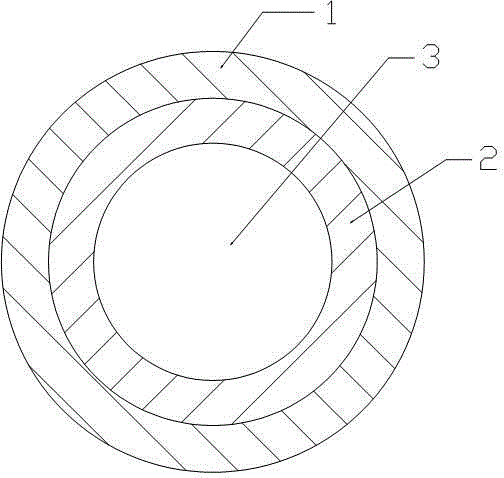

[0015] see figure 1 , the present invention relates to a cored wire, the cross section of the cored wire is circular or rectangular, the cored wire includes an outer sheath and a core material 3, the outer sheath includes an outer strip steel layer 1 and an inner metal layer 2. The metal layer 2 is an aluminum layer, and the core material 3 is uniformly mixed with silicon powder and calcium powder.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a core-spun yarn, the section of which is circular or rectangular. The core-spun yarn comprises an outer skin and a core material (3), wherein the outer skin comprises an outer strip steel layer (1) and an inner metal layer (2); the metal layer (2) is an aluminum layer; and the core material (3) is formed by uniformly mixing silicon powder and calcium powder. According to the core-spun yarn provided by the invention, as the outer skin comprises the outer strip steel layer and the inner metal layer and is used for preparing the core-spun yarn with the core material, and in a metal-stream inoculation process, the outer strip steel layer ensures the basic strength of the core-spun yarn. As the inner metal layer is the aluminum layer, the melting point of which is lower than that of steel, the melting time of the outer skin is integrally shortened under the condition that the basic strength of the core-spun yarn is ensured. In the molten steel treatment process, the core-spun yarn can be quickly molten to fully exert the effect of a powdery inoculant, so that the strength and toughness of the steel are guaranteed.

Description

technical field [0001] The invention relates to a cored wire, in particular to a cored wire for aluminum-iron alloys, and belongs to the technical field of refined steel. Background technique [0002] The cored wire is used in the deoxidation treatment of molten steel to improve the strength, toughness and electromagnetic orientation of the steel, which is called the inoculation treatment method. [0003] The existing cored wire is to wrap the core material with strip steel to make a sandwich steel sheet tube, and the cored wire is added into the molten steel with a wire feeder to complete the treatment of the molten steel. The current cored wire is covered with steel sheet for inoculation with flow. However, due to the high melting point of steel, it cannot be melted rapidly during the inoculation process, and the mixing of core material and molten iron is not uniform, and the core material cannot be fully utilized. The effect of the inoculant, so the treated steel cannot ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21C7/06

Inventor 朱宇洪

Owner JIANGYIN YURUI METALLURGICAL FURNACE CHARGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com