High-strength combination reinforced thermoplastic composite material board

A technology for reinforcing composite materials and enhancing thermoplastics, which can be used in sheet/board, building elements, layered products, etc., and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

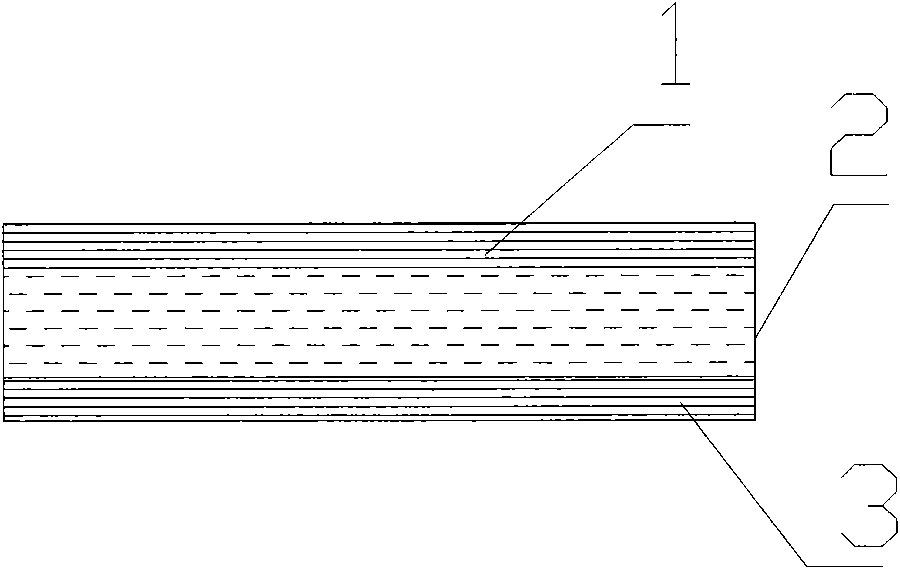

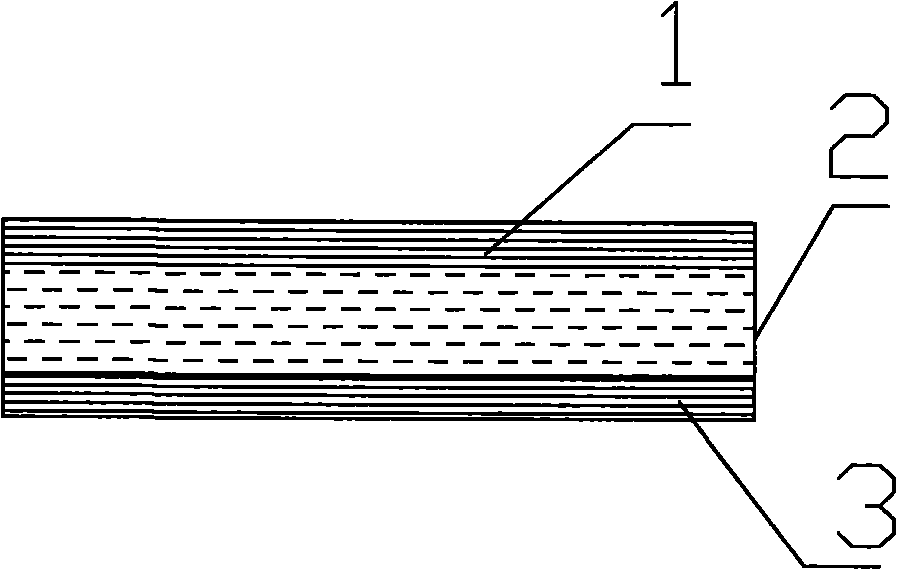

[0009] refer to figure 1 , the present invention has a three-layer structure, including an upper fabric layer 1 and a lower fabric layer 3 woven from blended yarns that are composed of glass fibers and polypropylene fibers, and a long glass fiber layer that is arranged between the upper and lower fabric layers. An extruded layer 2 that is homogeneously mixed with polypropylene. The blended yarn of the fabric layer is unidirectionally woven or bidirectionally woven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com