Steel structure

A technology of steel structure and pipe wall, applied in the direction of building structure, construction, etc., can solve the problems of inability to set up platforms, beams, and inconsistent appearance, and achieve the effect of simple structure, enhanced bearing capacity, and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

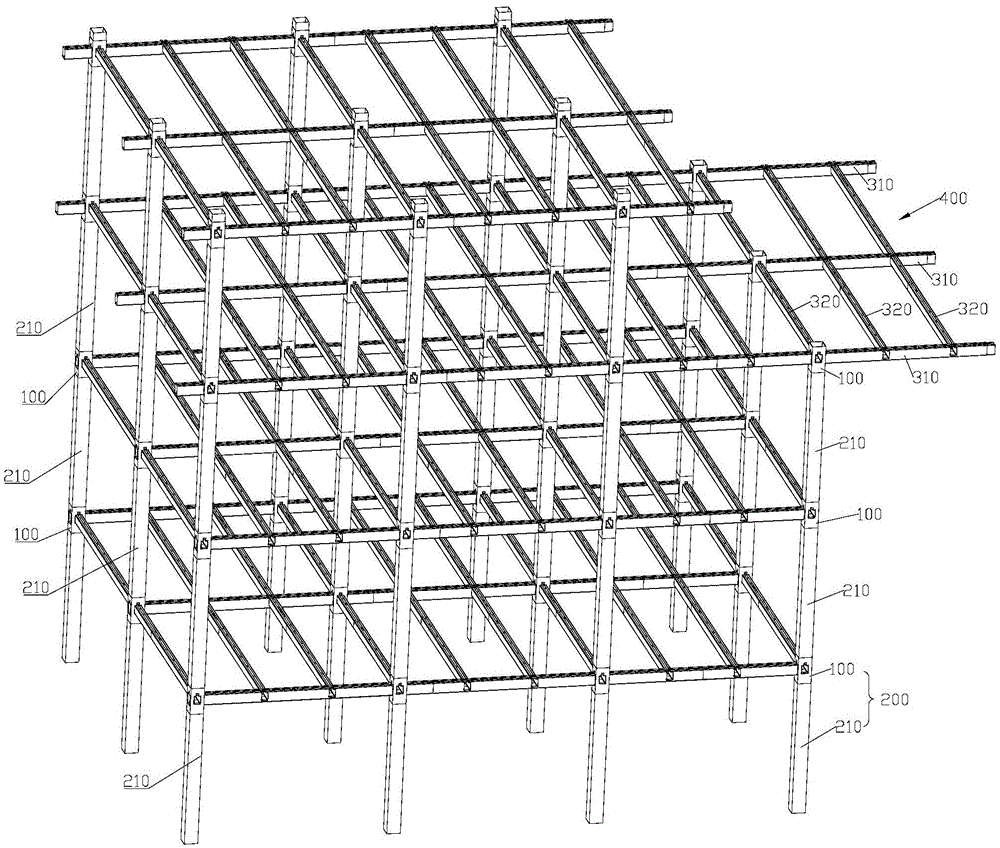

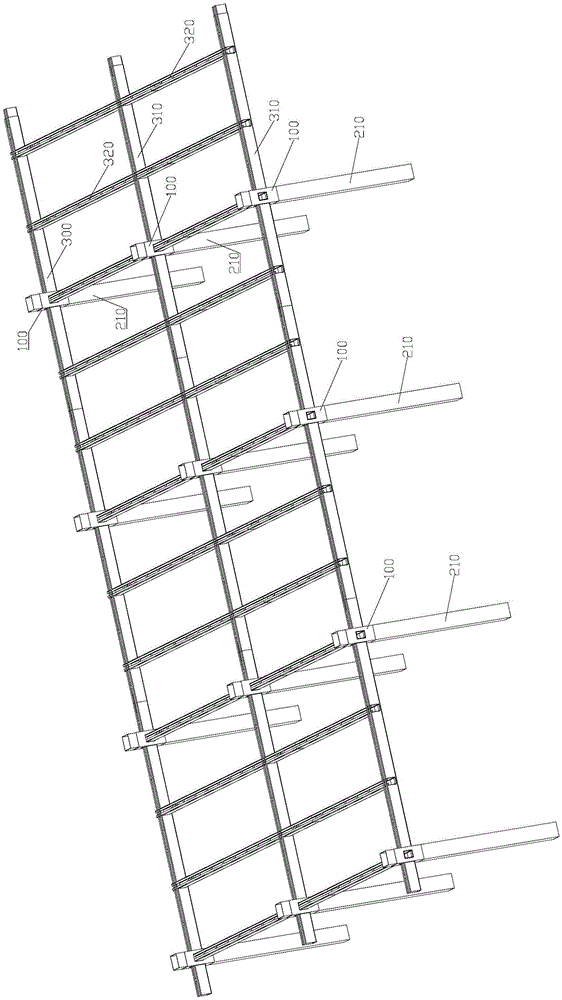

[0057] Such as figure 1 , figure 2 As shown, the steel structure includes multiple columns 200 , multiple main beams 310 and multiple secondary beams 320 . The column 200 includes a support column 210 and a corbel structure 100 . The corbel structure 100 is disposed at the end of the support column 210 . A plurality of support columns 210 are connected through the corbel structure 100 and are arranged in a multi-layer structure. On the right side of the third floor, there is a pick platform 400 . in such as figure 1 In the example shown, there are four layers. Such as figure 1 , figure 2 As shown, in each layer of steel structure, the main beam 310 and the secondary beam 321 pass through the corbel structure 100 . The corbel structure 100 connects the support column 210 with the main beam 310 and the secondary beam 320 . The support column 210 supports the main beam 310 and the secondary beam 320 . Each main beam 310 can be formed by connecting multiple sections, o...

Embodiment 2

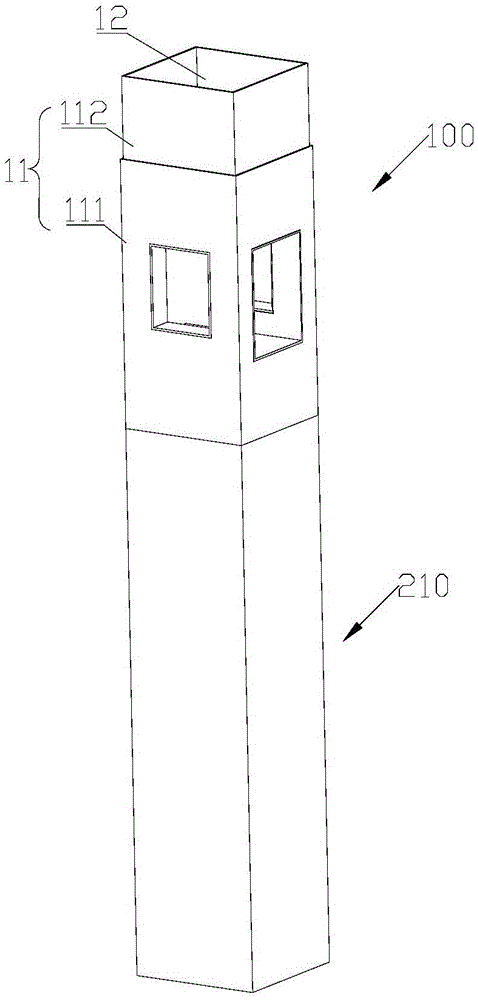

[0068] Such as Figure 10 , Figure 11 As shown, the corbel structure in this embodiment is different from that in Embodiment 1. The corbel structure 100 includes a casing 10 and a connecting piece 20 . Sleeve 10 structure such as Figure 5 shown. The casing 10 has a casing wall 11, the casing wall 11 encloses a casing lumen 12, and the casing wall 11 is provided with a first through hole 13 penetrating through the casing wall 11 . The shape of the casing wall 11 and the shape of the casing lumen 12 can be quadrangular or circular, and can also be selected as other shapes according to actual needs. The quadrilateral can be a rectangle, a square or other available shapes. In the example shown, the cannula wall 11 is rectangular and the cannula lumen 12 is also rectangular. The position and number of the first through holes 13 can be selected according to actual needs. In this embodiment, four first through holes 13 are respectively opened on four surfaces of the rectang...

Embodiment 3

[0075] Figure 13 The internal structure of the sleeve lumen in this embodiment is shown. The difference between this embodiment and Embodiment 1 is that the structure of the corbel is different. Such as Figure 13 As shown, the corbel structure includes a casing 10 and a connecting piece 20 . Sleeve 10 structure such as Figure 5 shown. The cannula 10 has a cannula wall 11 which encloses a cannula lumen 12 . The sleeve tube wall 11 is provided with a first through hole 13 penetrating through the sleeve tube wall 11 . The shape of the casing wall 11 and the shape of the casing lumen 12 can be quadrangular or circular, and can also be selected as other shapes according to actual needs. The quadrilateral can be a rectangle, a square or other available shapes. In the example shown, the cannula wall 11 is rectangular and the cannula lumen 12 is also rectangular. The position and number of the first through holes 13 can be selected according to actual needs. In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com