Bridge deck wet joint structure adopting T-head steel bars and construction method of bridge deck wet joint structure

A construction method and technology for wet joints, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of large welding workload of wet joints, large current traffic impact, cumbersome construction procedures, etc., to ensure construction quality, The effect of shortening construction time and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

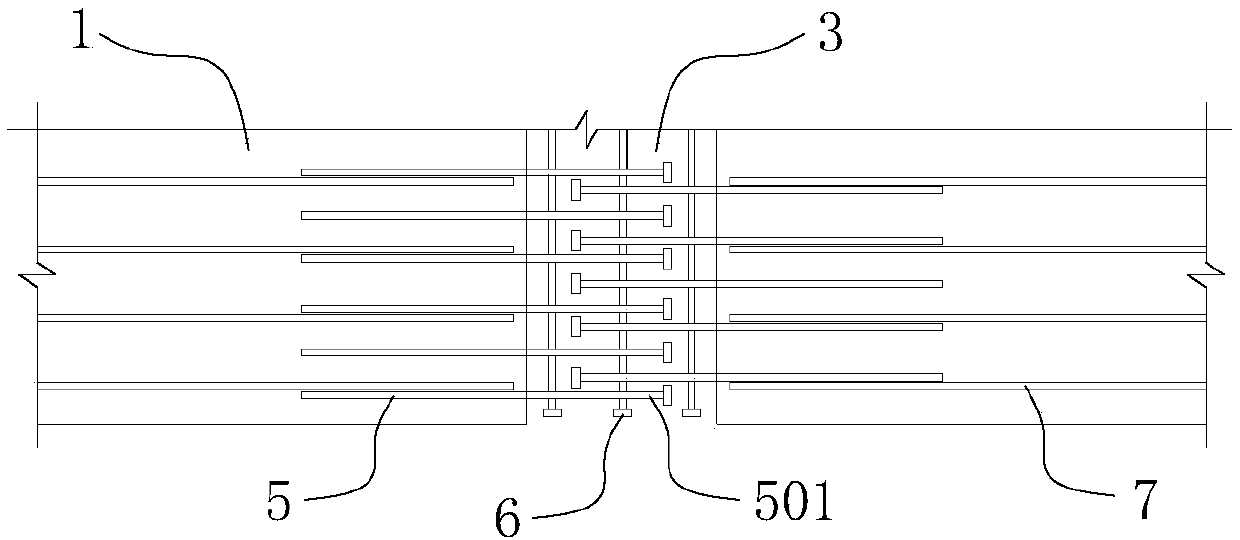

[0037] This embodiment discloses a steel-concrete composite girder precast concrete bridge deck wet joint structure using T-head steel bars, including a plurality of precast concrete bridge decks 1 erected on steel beams.

[0038] The prefabricated concrete bridge deck 1 is the roof of the steel-concrete composite beam, which is prefabricated in the prefabrication factory. The prefabricated concrete bridge deck 1 is provided with upper and lower layers of common steel bars 7 for the concrete bridge deck. see figure 1 , wet joints 3 are formed at intervals between two adjacent precast concrete bridge decks 1 .

[0039] The upper and lower layers of T-head steel bars 5 are pre-embedded on the side near the wet joint of the precast concrete bridge deck 1 . The pre-embedded part of the T-head steel bar 5 in the bridge deck overlaps with the common steel bar 7 of the concrete bridge deck. The part of the T-head reinforcing bar 5 protruding from the precast concrete bridge deck 1...

Embodiment 2

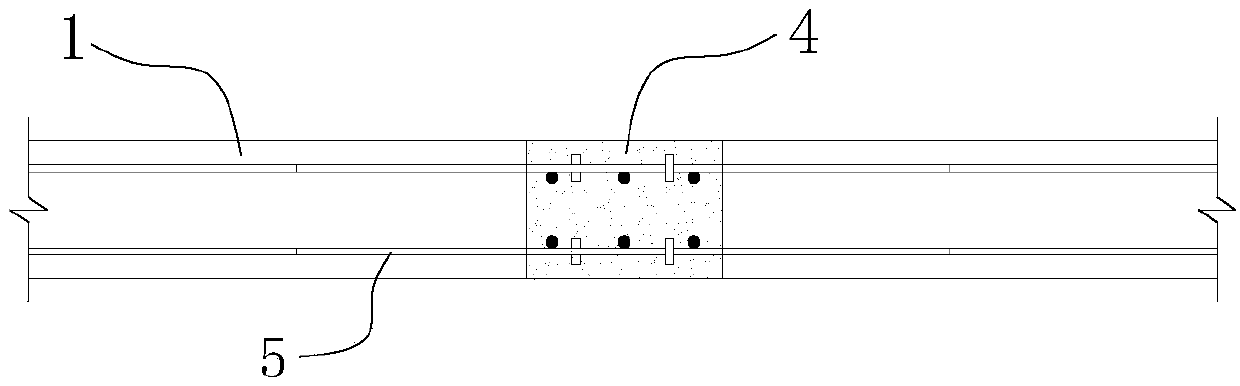

[0043] This embodiment discloses a bridge deck wet joint structure using T-head steel bars, including a plurality of prefabricated beams 2 arranged along the bridge direction.

[0044] see image 3 , the prefabricated beam 2 is a precast concrete T-beam. Wet joints 3 along the bridge direction are formed at intervals between two adjacent prefabricated beams 2 . The side near the wet joint of the prefabricated beam 2 is the horizontal section 201 of the prefabricated beam bridge deck. see image 3 T-head reinforcing bars 5 extending to wet joints 3 are arranged in the horizontal section 201 of the prefabricated beam bridge deck. The T-head anchor ends 501 between the adjacent prefabricated beam horizontal sections 201 are arranged in a staggered manner. The projections corresponding to the T-head anchoring end 501 have a length overlap.

[0045] In-situ wet joint concrete 4 is cast in the wet joint 3 . The wet joint concrete 4 is made of high-performance low-shrinkage or mi...

Embodiment 3

[0047] This embodiment discloses a bridge deck wet joint structure using T-head steel bars, including a plurality of prefabricated beams 2 arranged along the bridge direction.

[0048] see Figure 4 , the prefabricated beam 2 is a precast concrete small box girder. Wet joints 3 along the bridge direction are formed at intervals between two adjacent prefabricated beams 2 . The side near the wet joint of the prefabricated beam 2 is the horizontal section 201 of the prefabricated beam bridge deck. T-head reinforcing bars 5 extending to wet joints 3 are arranged in the horizontal section 201 of the prefabricated beam bridge deck. The T-head anchor ends 501 between the adjacent prefabricated beam horizontal sections 201 are arranged in a staggered manner. The projections of the corresponding T-head anchoring ends 501 along the length direction of the wet joint have a length overlap.

[0049] In-situ wet joint concrete 4 is cast in the wet joint 3 . The wet joint concrete 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com