Integral fast-assembly type steel-structure elevator

A quick-installation, steel structure technology, applied to elevators, transportation and packaging, elevators, etc. in buildings, can solve problems such as long construction period, affecting residents' travel and life, and achieve the effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

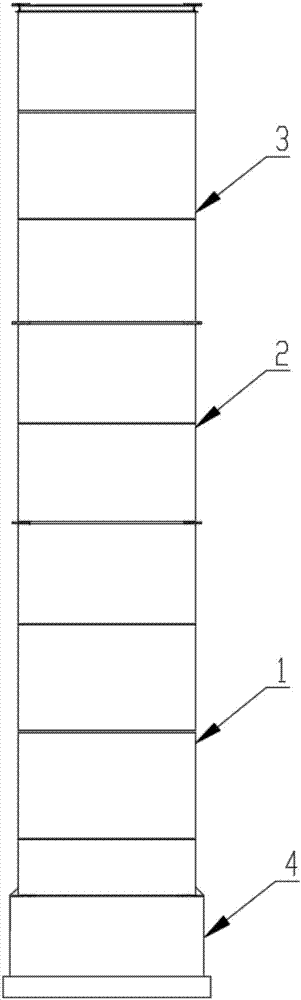

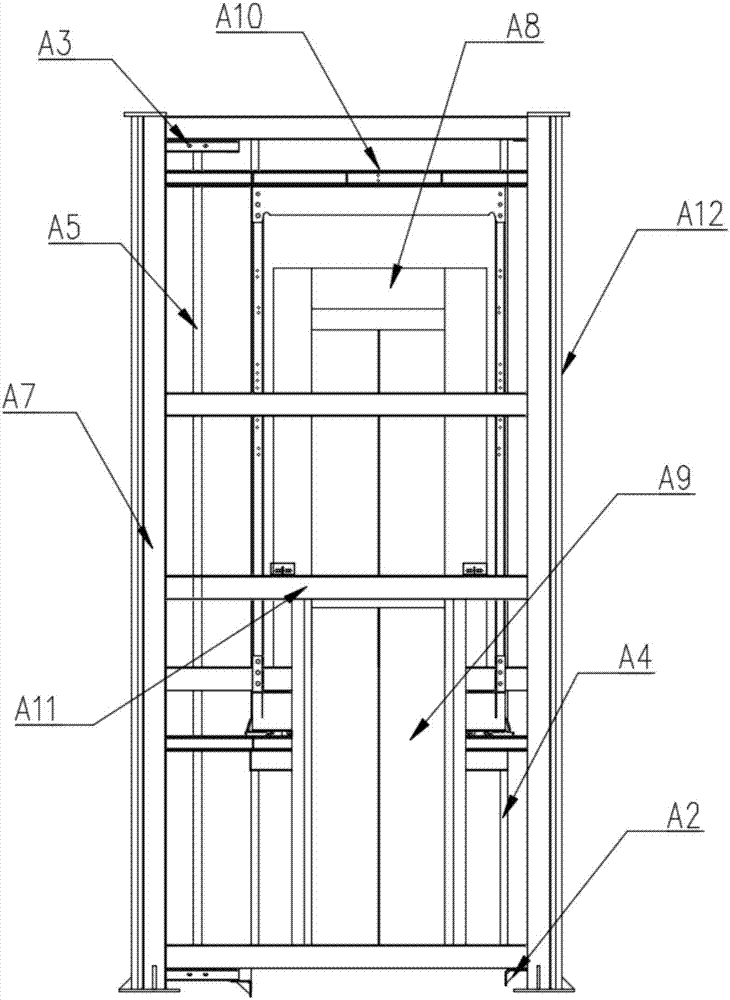

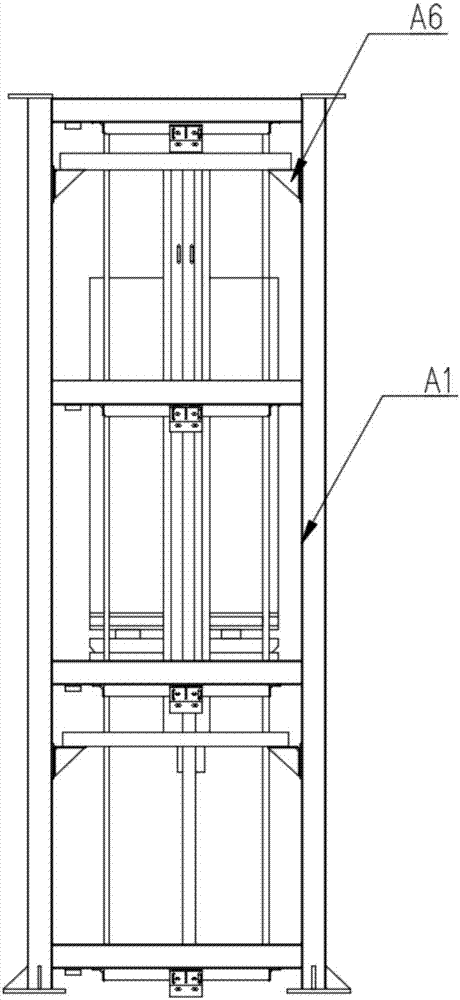

[0018] Such as Figure 1-5 As shown, an integral quick-loading steel structure elevator is composed of the first modular segment 1, the middle modular segment 2, and the top modular segment 3. The first modular segment is set above the elevator pit 4. In section 1, the middle modular section 2 is set above the first modular section 1, and the top modular section 3 is set above the middle modular section 2.

[0019] The first modular segment 1 consists of the first frame A1, the main rail bracket A2, the shared rail bracket A3, the main rail A4, the counterweight guide rail A5, the car fixing frame bracket A6, the first frame column A7, and the car assembly A8 , Landing door system A9, car fixing frame A10, first section frame beam A11, exterior decoration A12, the two sides of the first section frame A1 are provided with main rail bracket A2, shared guide rail bracket A3, main rail bracket A2, shared guide rail bracket A3 The main rail A4 and the counterweight guide rail A5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com