Prefabricated inspection well and road construction method involving inspection well

A road construction, prefabricated technology, applied in the field of manholes, can solve problems such as affecting road quality, delaying construction progress, inconsistent subgrade density, etc., and achieve the effects of reducing labor usage and road construction costs, increasing road surface smoothness, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention arranges the road repair method of inspection well, and its steps are:

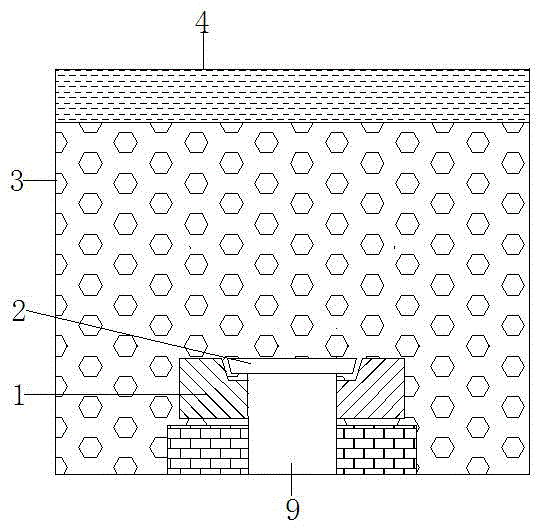

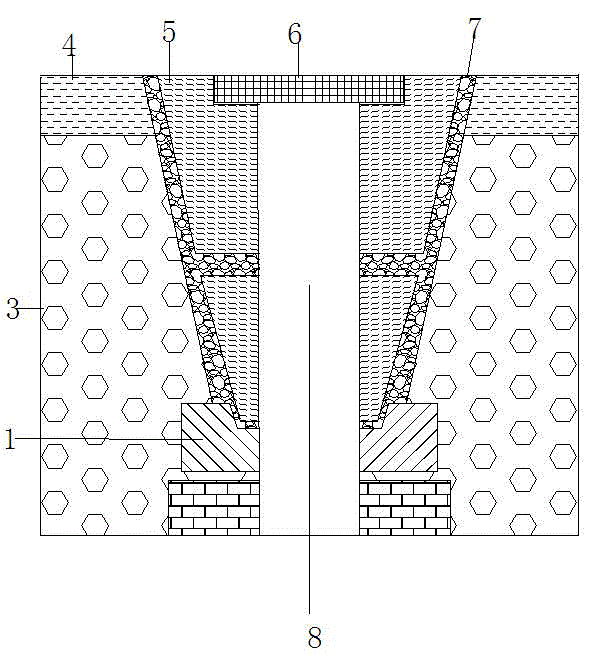

[0030] 1. At the preset positions of the pipelines and cable trenches 9 under the subgrade, a inspection well base 1 with a circular opening is arranged.

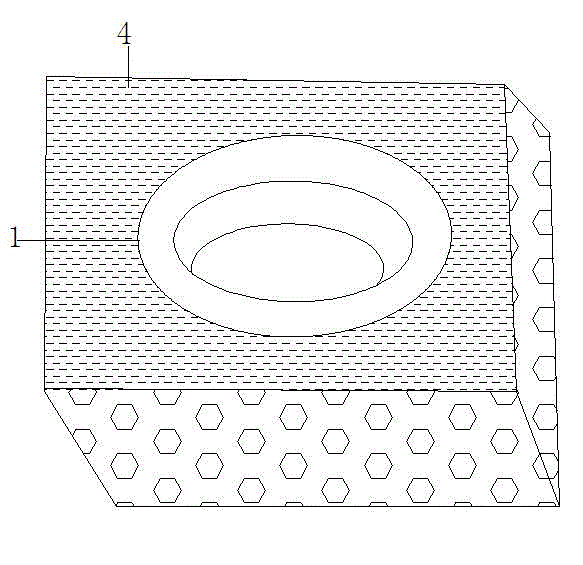

[0031] 2. Install the bottom cover 2 on the base 1 that can be detected across the roadbed 3 and road surface 4, or install a signal transmitter on the bottom cover 2 (usually placed in the center), or use GPS, Beidou and other positioning systems Precise positioning of the bottom cover 2 (the positioning accuracy of the civil GPS system has theoretically reached the millimeter level, and the positioning accuracy of the Beidou system in some areas of China is even higher). The installed bottom cover 2 is approximately flush with the tops of the pipes and cable trenches 9, and the bottom cover 2 and the base 1 are adapted so that soil, sand, etc. will not just fall through the gap between them;

[0032] 3. Lay the subgrade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com