Assembly type light pipeline hanger

A pipe hanger and assembly technology, which is applied in the direction of pipe supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of poor production environment, long production cycle, and large amount of steel, and achieve short production cycle and assembly Simple, paint-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

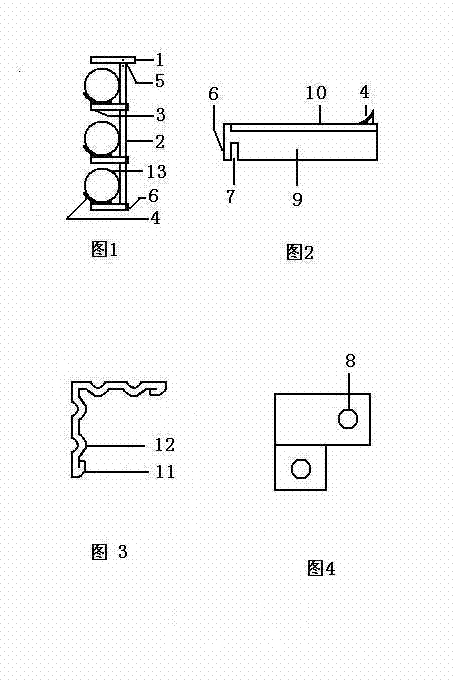

[0016] exist figure 1 , 2 , In the embodiment of 3 and 4, the assembled light pipe hanger is composed of a fixed beam 1, a connecting beam 2, a pipe joist 3, and a connector 5, and the fixed beam 1, the connecting beam 2, and the pipe joist 3 are made of metal Plates, such as galvanized sheets, are rolled and pressed into crimps 11 and rectangular beams with reinforcing grooves 12 and processed separately. The assembled light pipe hanger is assembled and fixed by bolts. The connection between the fixed crossbeam 1 and the connection suspension beam 2 is connected by a connector 5 , and the connection between the pipe joist 3 and the connection suspension beam 2 is connected by a connection pin 6 and a connection groove 7 .

[0017] Connector 5 is made of square profile, and is combined into a right-angle shape by connecting two sides. The outer edge size of connector 5 is equal to the inner angle size of the right-angle beam, and the center line position of two sides of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com