Floor formed by combining cold-formed thin-wall C-shaped steel and straw plates and manufacturing method

A straw board, cold-formed thin-wall technology, used in floor slabs, monocarboxylate copolymer adhesives, flat products, etc., can solve problems such as self-weight, achieve small self-weight, reduce construction time, improve stiffness and load bearing. The effect of force problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

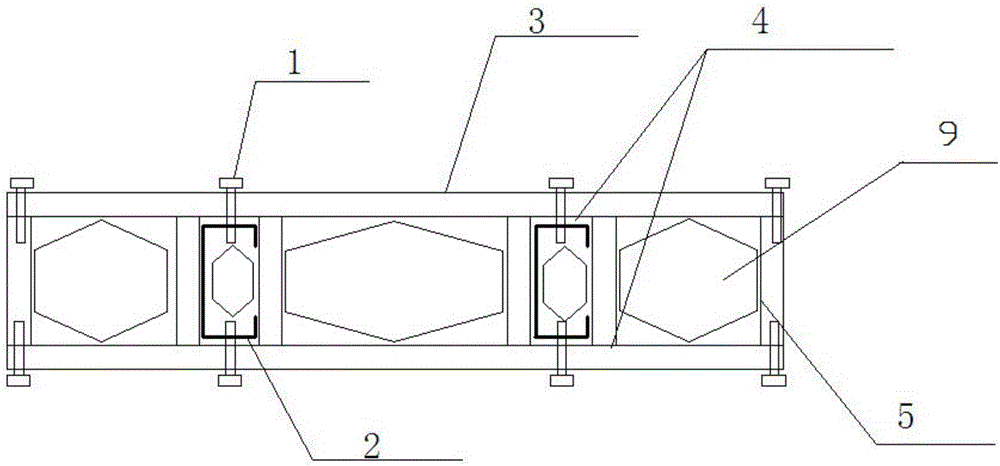

[0033] see Figure 1-2 , the present invention provides a technical solution: the composite floor is composed of two straw plates 3 sandwiching two cold-formed thin-walled C-shaped steel 2, and the straw plate 3 and the cold-formed thin-walled C-shaped steel 2 are glued with high-strength structure The self-tapping screw 1 is driven into the 4 positions of the solidified cemented surface, and the longitudinal side of the floor is sealed 5 with 3 straw plates, and the upper and lower parts are connected by screws. There is a cavity in the composite plate, and the thermal insulation and sound insulation materials, and can also easily pass through wires and other pipelines. The straw plate 3 is a high-strength material, and the use of a solid cross section is not conducive to fully exerting its material strength. Since the bonding between the cold-formed thin-walled C-shaped steel 2 and the straw plate 3 can produce a good combination effect through the bonding of high-strength st...

Embodiment 2

[0035] An assembly method of a floor slab composed of cold-formed thin-walled C-shaped steel and straw plates:

[0036] S1, two straw plates are processed, and several barbs are respectively processed on the connecting surface of the straw plates and the cold-formed thin-walled C-shaped steel, and the barbs are engaged with the ribs of the cold-formed thin-walled C-shaped steel;

[0037] S2, cold-bending the upper and lower ends of the thin-walled C-shaped steel to cold-bend outward extensions, and processing several ribs on the upper and lower sides of the cold-formed thin-walled C-shaped steel connected with the straw plate;

[0038] S3, apply glue on the connecting working surface of the two straw plates;

[0039] S4, placing a plurality of cold-formed thin-walled C-shaped steels between two straw plates, and fixing and connecting the top straw plate and cold-formed thin-walled C-shaped steel upper and lower end cold-formed outward extensions through the self-tapping screws...

Embodiment 3

[0043] The production steps of the straw board include:

[0044] a, removing impurities from the collected cotton stalks and crushing them to screen out stalk particles with a length of 100 mm and a width of 20 mm, and drying until the moisture content is less than 5%;

[0045] b, mix 52% by weight of straw granules, 14% by weight of sawdust, 11% by weight of gypsum, 30% by weight of magnesium powder, 1.2% by weight of sulfuric acid solution and 0.5% by weight of glycerin, add 60% water, after stirring for 60 minutes, put it into the mold and form it in the press, after it is formed, slowly release the pressure, trim the semi-finished product taken out and dry it at 150°C for 2 days, and finally put it into the pressure maintenance mold , dried and cured for 15 days, the cotton straw board is obtained.

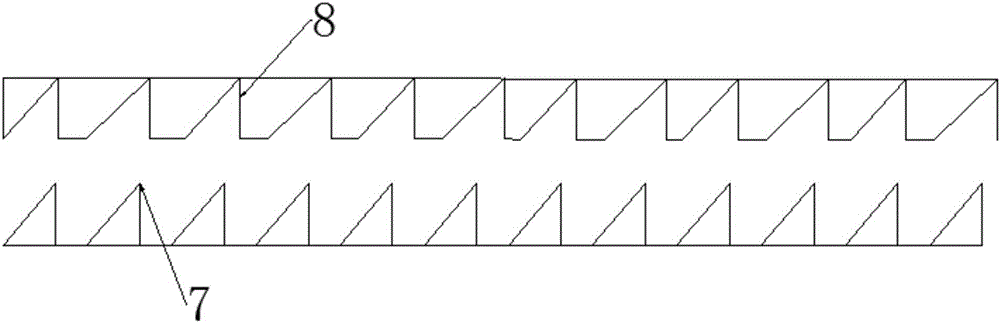

[0046] The connecting surface of the cold-formed thin-walled C-shaped steel 2 is provided with several ribs 8, and the connecting surface of the straw plate 3 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com