Node connecting structure for assembled bamboo wood beam column

A beam-column joint, prefabricated technology, applied in building structure, construction, etc., can solve the problems of less optimization of structural performance, low production efficiency, complicated installation, etc., and achieve stable beam-column joint connection structure and convenient on-site installation. , The effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

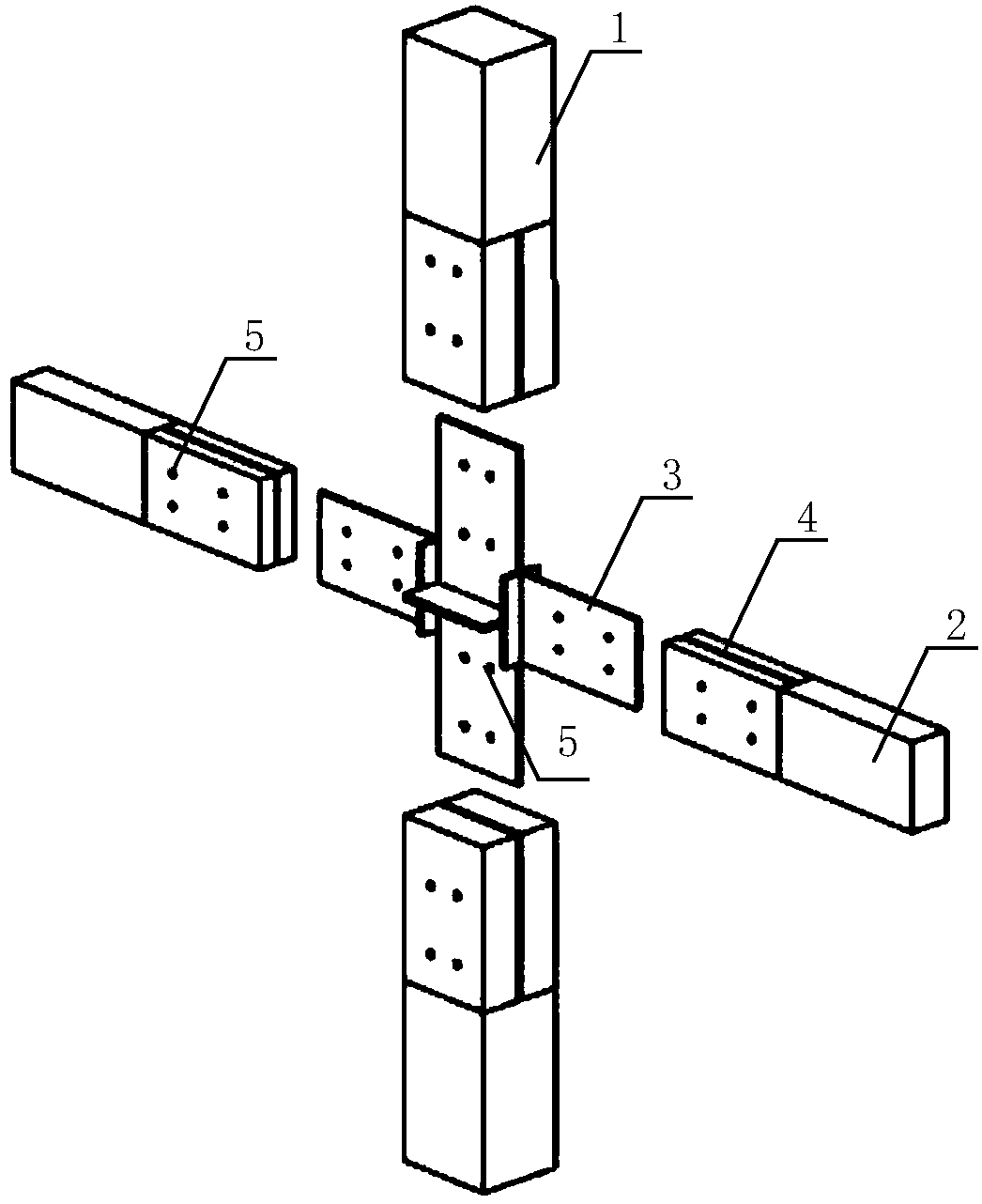

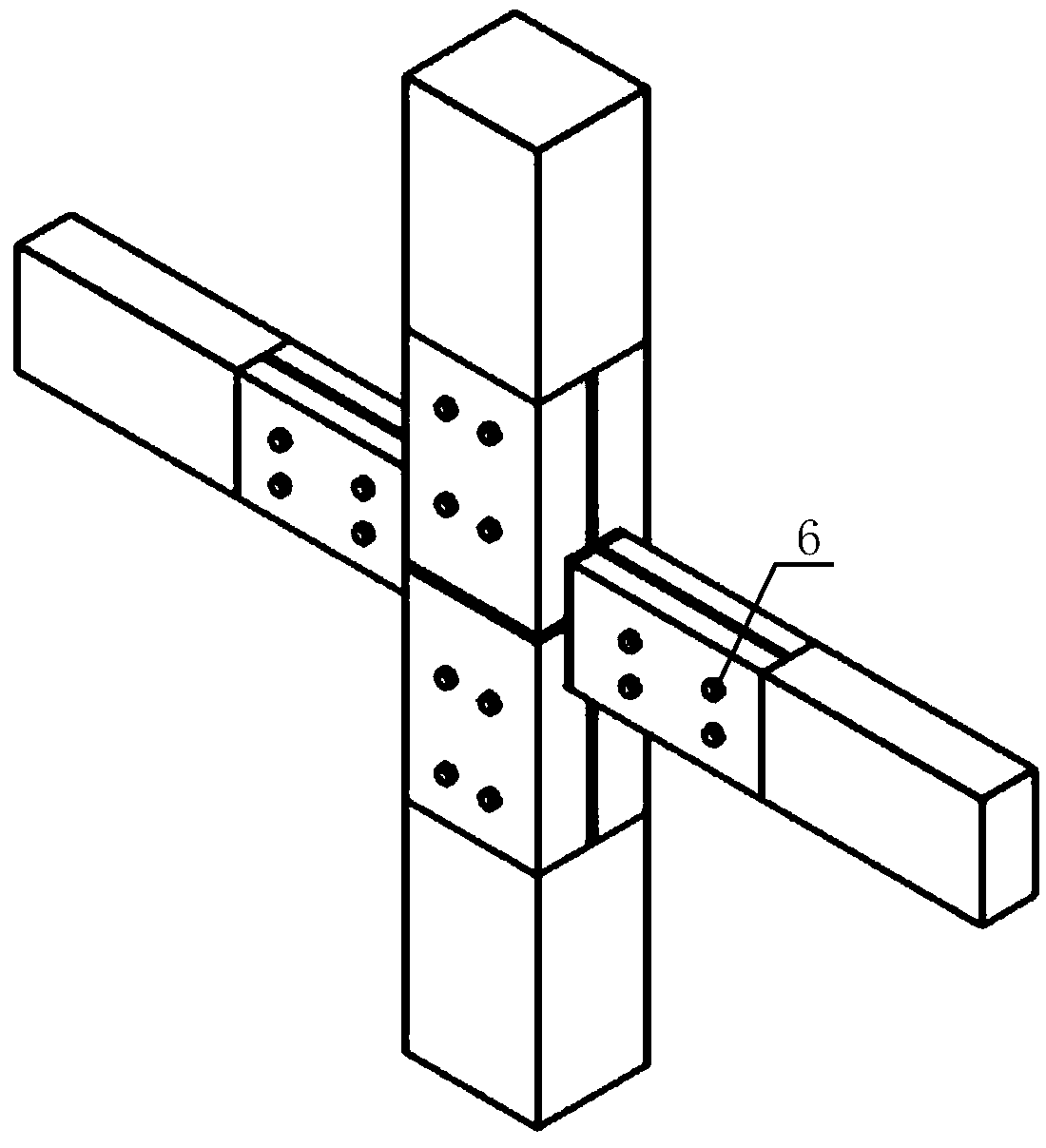

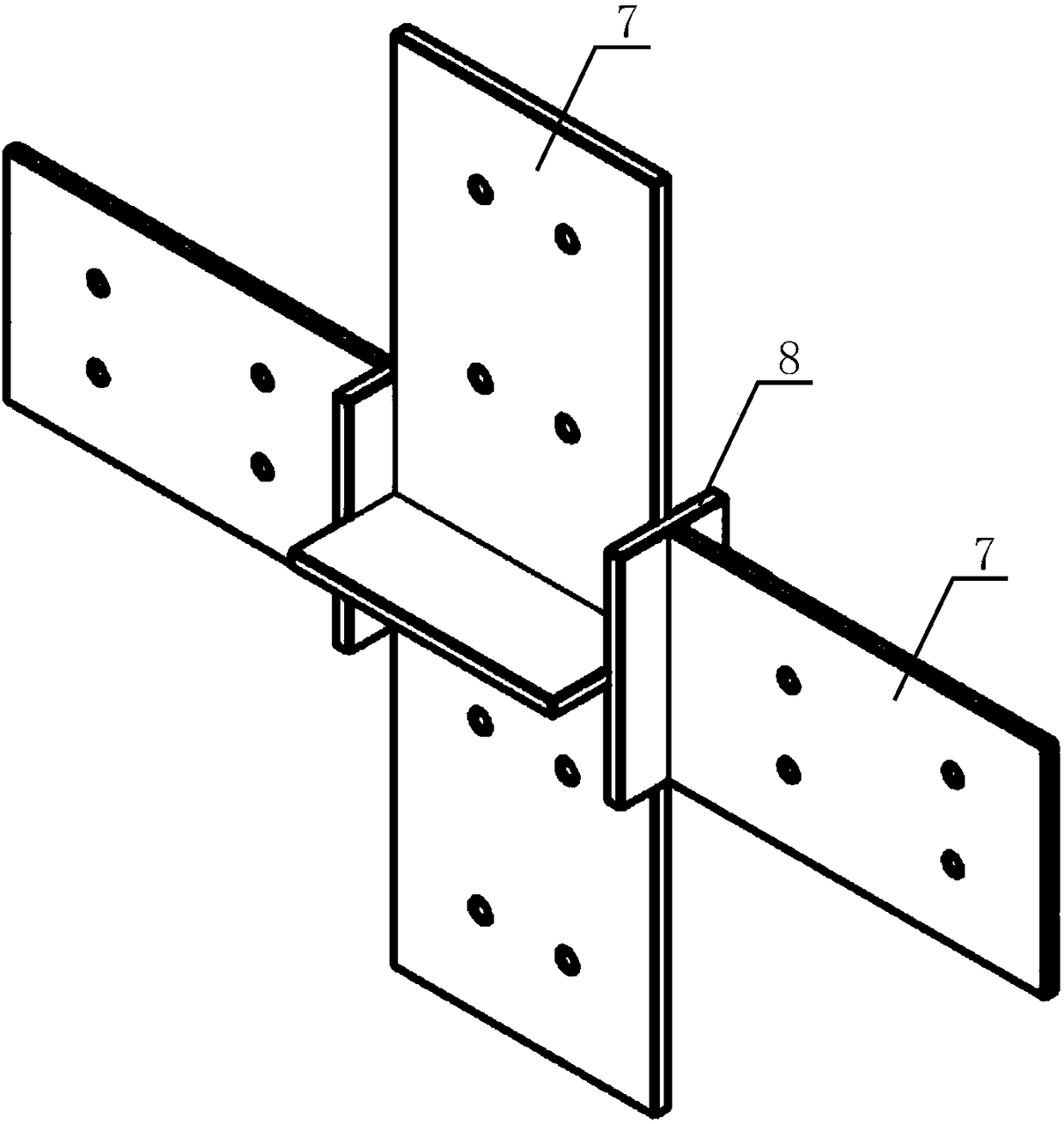

[0019] Such as Figure 1-4 As shown, a prefabricated bamboo-wood beam-column joint connection structure includes a rectangular side column 1, a rectangular beam 2, a steel filler plate 3, and a tension bolt 6. The steel filler plate 3 is spliced into an H shape by steel plates, and The corresponding part of the beam-column connection adopts the fillet weld method to weld the wing plate according to the principle of equal strength to form a whole. The size of the welding leg should be determined according to the plate thickness, force and structure requirements. At the same time, the edge of the weld seam is ground into a right angle, which is convenient for the installation of rectangular beams and columns. The thickness of the steel plate in the steel filler plate shall be determined according to the shear force and bending moment borne by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com