Fabricated combined connecting beam window opening component, structure and manufacturing and construction method

A combined connection and assembly technology, applied in truss structures, building components, girders, etc., can solve problems such as damage, achieve the effect of ensuring overall quality, improving ductility and energy dissipation capacity, and facilitating concrete construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

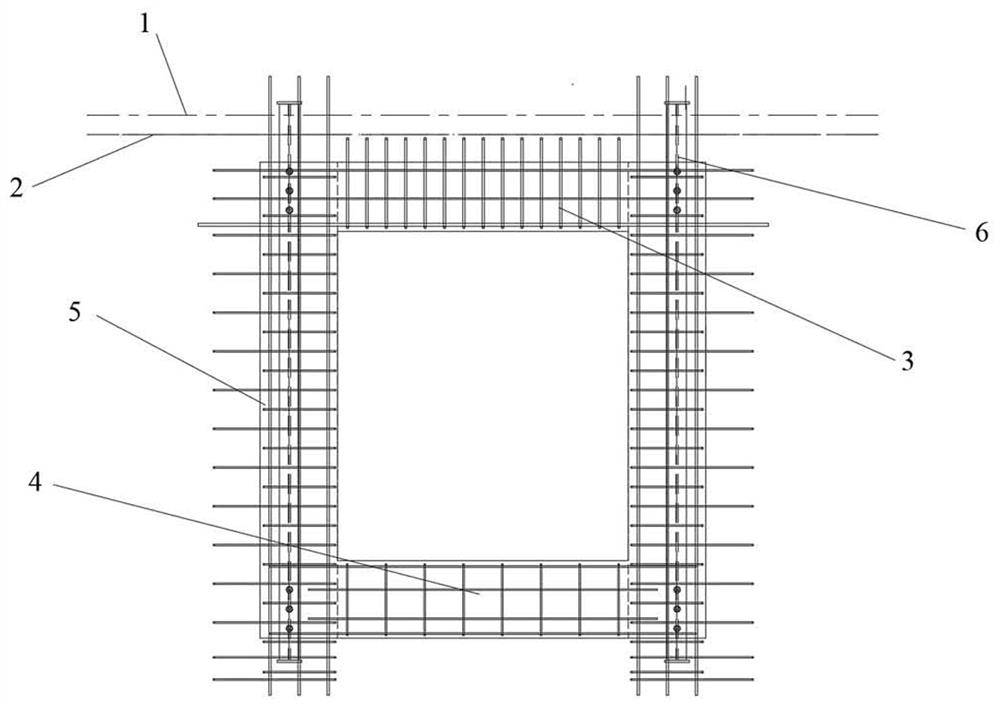

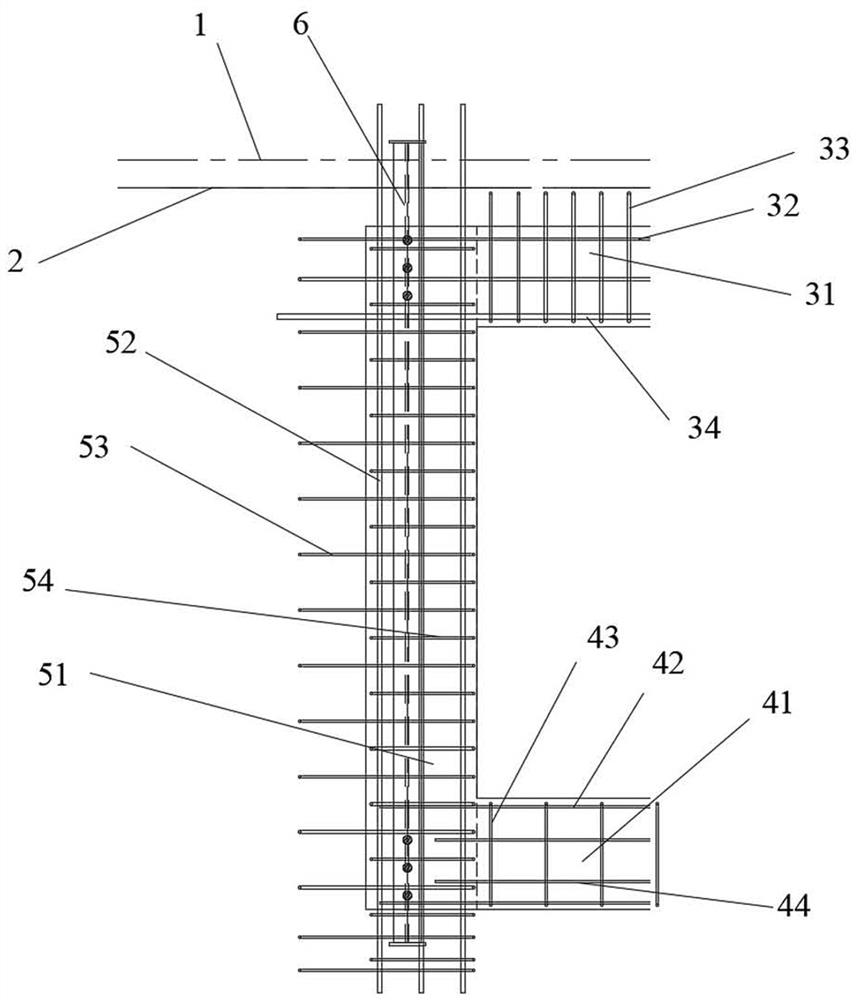

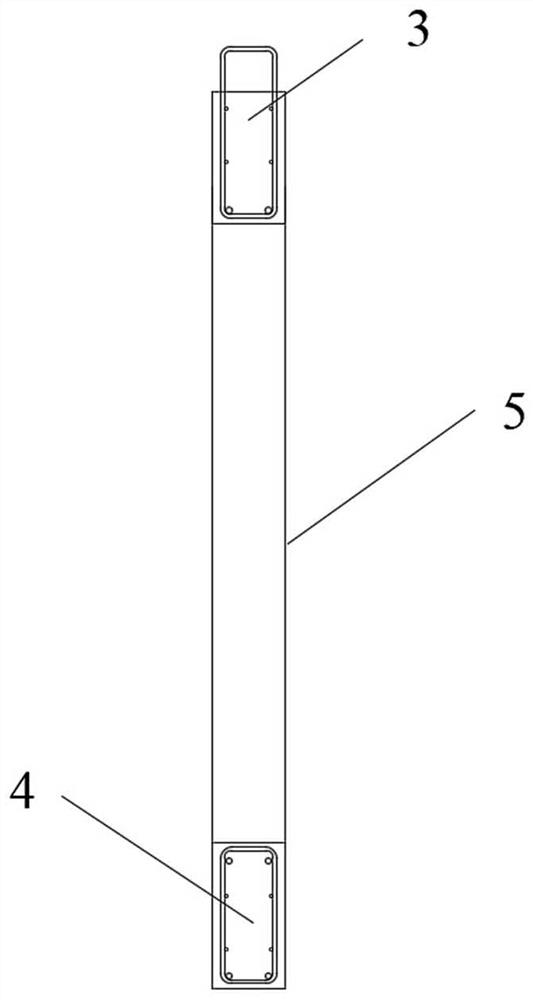

[0046] Such as Figure 1 to Figure 5 As shown, a prefabricated composite connection beam window opening component includes two adjacent shear walls, a top connection beam 3 connected to the bottom of the shear wall roof, a window wall 4 connected to the bottom of the shear wall, and a top connection beam connected to the top slab. The wall concealed column 5 on both sides of the connecting beam 3 and the window wall 4 and the steel connector 6 connected in the wall concealed column 5 . The top connecting beam 3, the window wall 4 and the shear walls on both sides enclose the opening; the top connecting beam 3 is a semi-prefabricated beam, and the window wall 4 is a fully prefabricated window wall 4. Light fillers can be placed inside the prefabricated window wall 4, and the fillers include insulation boards and the like.

[0047] In the present embodiment, the concealed column 5 of the wall is a prefabricated or semi-prefabricated concrete column, comprising a concealed colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com