Regenerated concrete segmented beam and construction method thereof

A technology of recycled concrete and construction methods, applied in the direction of joists, girders, truss beams, etc., can solve the problems that cannot be applied and promoted, reduce structural reliability, and use less, so as to ensure construction quality and mechanical performance, and good The effect of force performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] 1 method

[0082] Through the cast-in-place method, comparing the influence of concrete mix ratio in different shear-dominant sections, design and pour segmental beam 1, segmental beam 2 and ordinary frame beam 1.

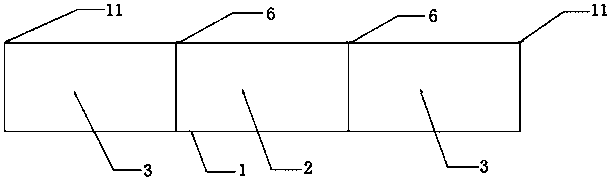

[0083] Such as figure 1 As shown in , the segmented beam is divided into a section dominated by bending moment and two sections dominated by shear force. The two sections dominated by shear force are respectively located on both sides of the section dominated by moment. pouring. Interface 1 and Interface 2 are set. Interface 1 is set between the moment dominant section and shear force dominant section, and interface 2 is set between the shear force dominant section and the frame column. Reinforcement cages include full-length steel bars, additional steel bars for supports, waist bars, and stirrups, which are built into segmented beams as skeletons. Segmented beams apply to frame or secondary beams in structural members, not to coupling or cantilever beams...

Embodiment 2

[0098] 1 method

[0099] Table 3 Mix ratio of natural concrete and recycled concrete used in construction

[0100]

[0101] Through the cast-in-place method, the effect of the concrete mix ratio in the sections with different bending moments is compared, and the pouring of segmental beams 1, 3, 4 and ordinary frame beam 1 is designed. Such as figure 1 As shown in , the segmented beam is divided into a section dominated by bending moment and two sections dominated by shear force. The two sections dominated by shear force are respectively located on both sides of the section dominated by moment. pouring. Interface 1 and Interface 2 are set. Interface 1 is set between the moment dominant section and shear force dominant section, and interface 2 is set between the shear force dominant section and the frame column. Reinforcement cages include full-length steel bars, additional steel bars for supports, waist bars, and stirrups, which are built into segmented beams as skeletons...

Embodiment 3

[0109] 1 method

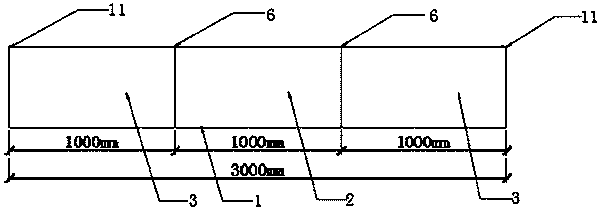

[0110] Through the cast-in-place method, the effects of different length ratios of the dominant sections are compared, and the segmental beams 1 and 5 and the ordinary frame beam 1 are designed and cast.

[0111] Such as figure 1 As shown in , the segmented beam is divided into a section dominated by bending moment and two sections dominated by shear force. The two sections dominated by shear force are respectively located on both sides of the section dominated by moment. pouring. Interface 1 and Interface 2 are set. Interface 1 is set between the moment dominant section and shear force dominant section, and interface 2 is set between the shear force dominant section and the frame column. Reinforcement cages include full-length steel bars, additional steel bars for supports, waist bars, and stirrups, which are built into segmented beams as skeletons.

[0112] The pouring steps of the cast-in-place method are consistent with those in Example 1. Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com