Coaxial extension welding method for steel bars

A welding method and steel bar technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult control of coaxial welding, achieve the effect of convenient and practical operation, and ensure the mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method of the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

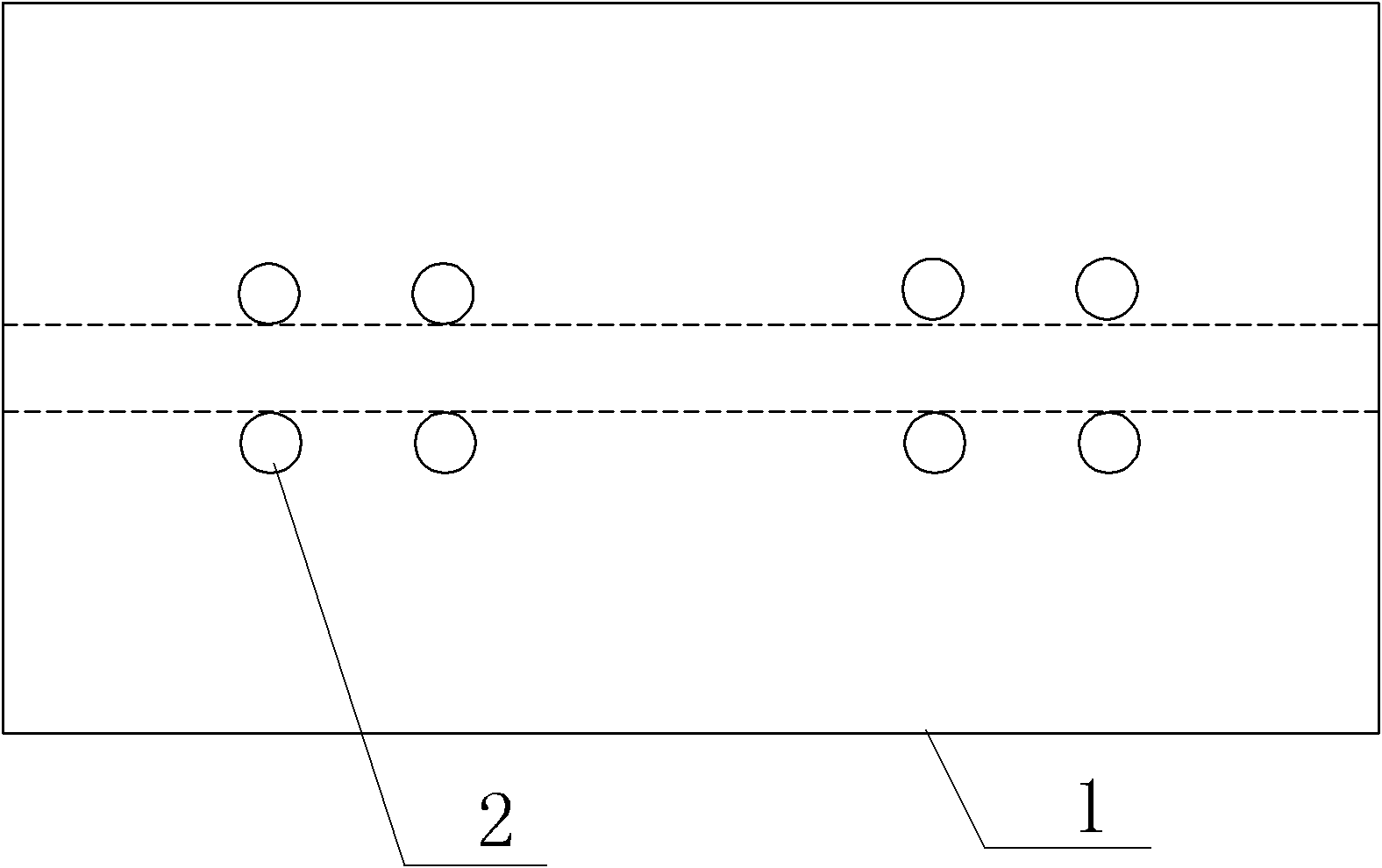

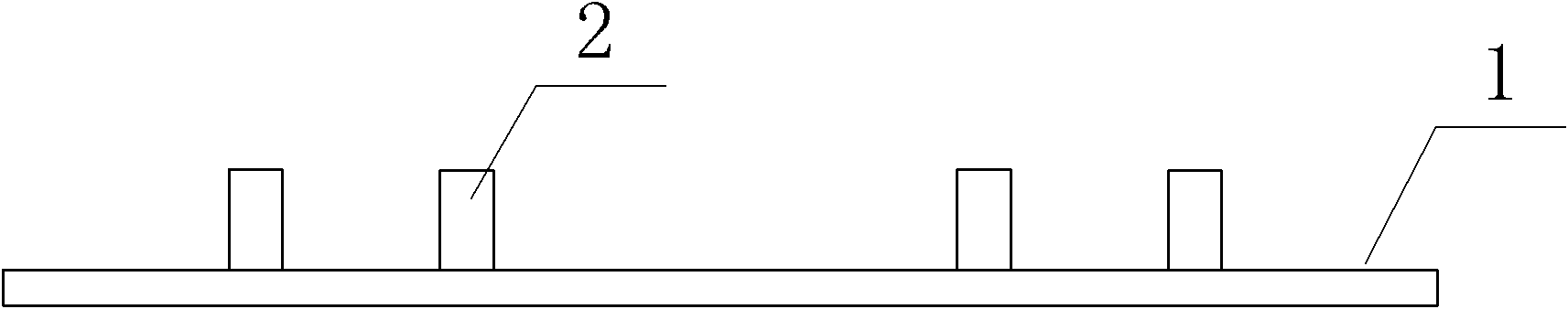

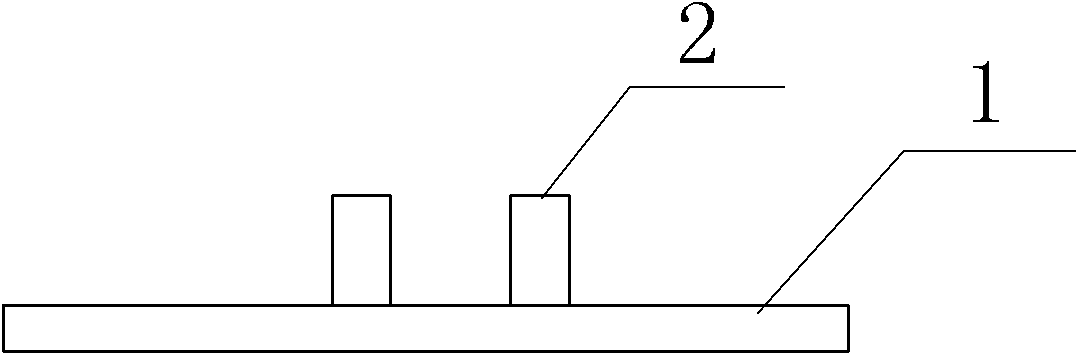

[0019] Before the present invention carries out the coaxial extension welding of two steel bars, a steel bar welding positioner will be made earlier, and its structure is shown in figure 1 , figure 2 , image 3 shown. The specific method is as follows:

[0020] On a steel plate 1, along two parallel straight lines ( figure 1 Two dotted lines in the middle), fixedly set two rows, four reinforcing bar positioning columns 2 in each row, each reinforcing bar positioning column 2 is all perpendicular to the surface of the steel plate 1; the distance between the two rows of reinforcing bar positioning columns 2 is, figure 1 The distance between the two dotted lines in , is equal to the diameter of the bar to be welded.

[0021] Among the four reinforcing bar positioning columns in each row, the distance between the two reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com