After-embedding mechanical cold connection wall body drawknot rib construction member and installation method

A cold connection and component technology, applied in building construction, building material processing, construction, etc., can solve problems such as insufficient progress, quality and safety, achieve simple and easy implementation methods, ensure mechanical performance, and reduce contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

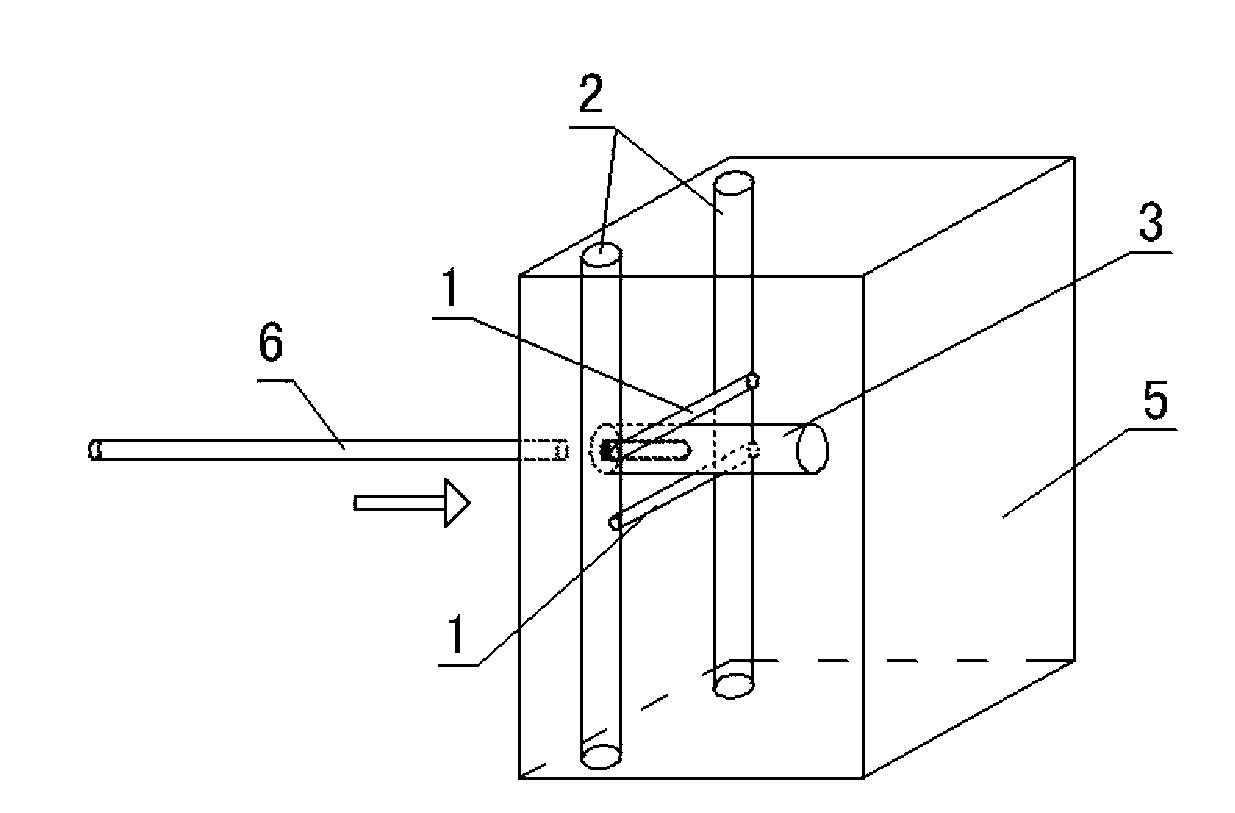

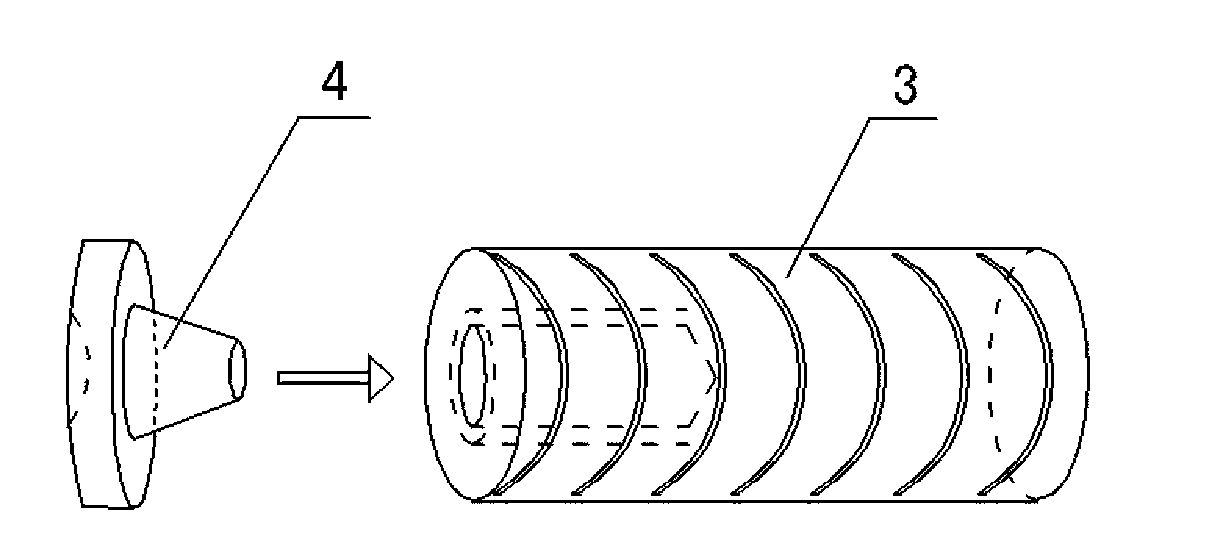

[0020] see figure 1 , figure 2 In this embodiment, the structural form of the wall tie-bar member that is pre-embedded and then mechanically cold-connected is to set a pre-embedded structure in the concrete member 5, and the pre-embedded structure is fixed and welded on the member stressed steel bar 2 in the member 5. A pair of positioning steel bars 1, the wire sleeve 3 is spot welded and fixed between the pair of positioning steel bars 1; the tie bar 6 is connected with the wire sleeve 3 by the end of the wire; the matching device is composed of a cap and a plug head The plastic blocking member 4 is blocked on the outer end of the threaded sleeve 3 by the plastic blocking member 4 and can be disassembled.

[0021] In this embodiment, the wall tie-bar members that are pre-embedded and then mechanically cold-connected are installed according to the following process:

[0022] 1. Reliably weld the positioning steel bar 1 and the structural member stressed steel bar 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com