Pipe segment joint type shield tunnel structure

A technology for shield tunneling and segment joints, which is applied in tunnels, tunnel linings, shaft linings, etc. It can solve the problems of gasket staggered seam and opening, affecting waterproof effect, and reducing mechanical performance, so as to facilitate replacement and avoid Partial waterproof seal failure, the effect of improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

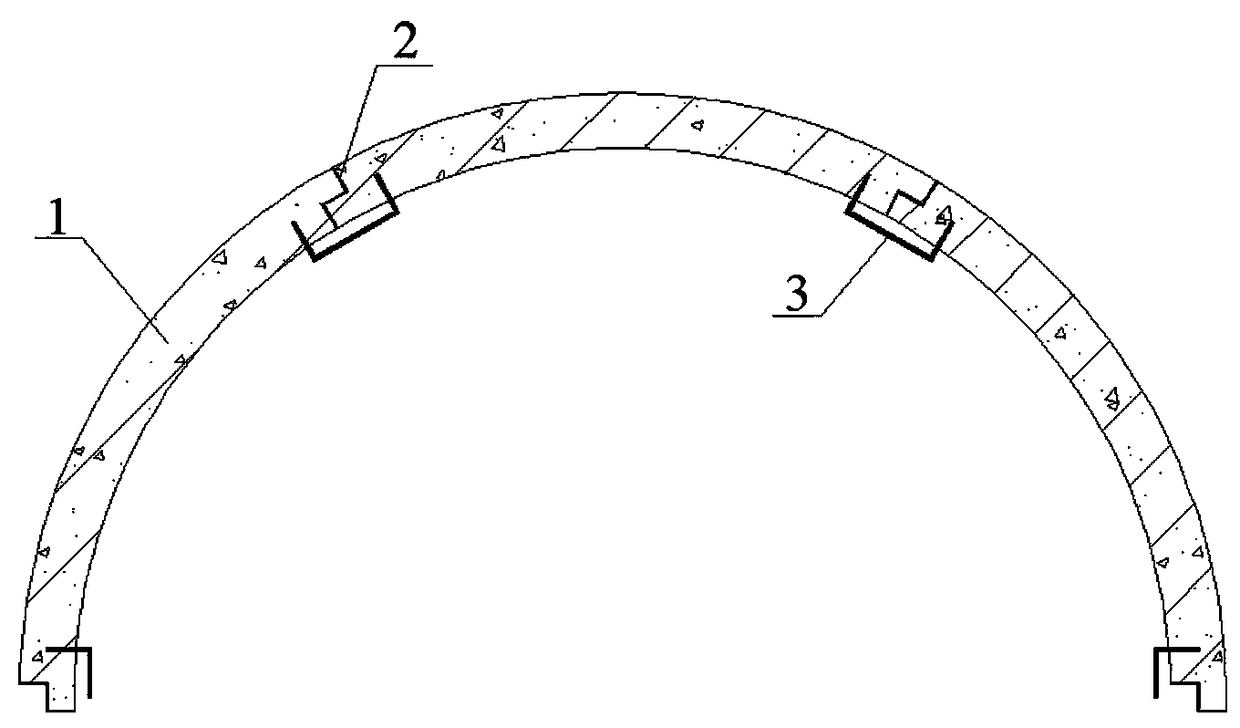

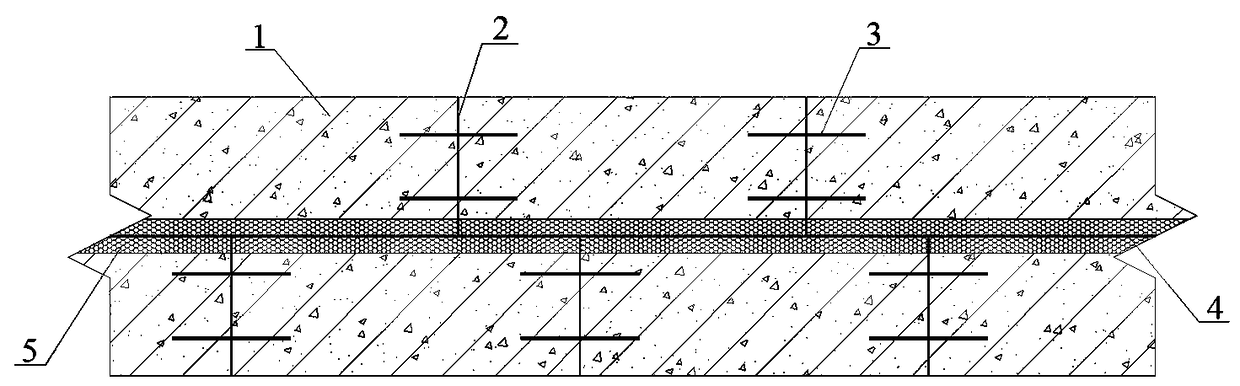

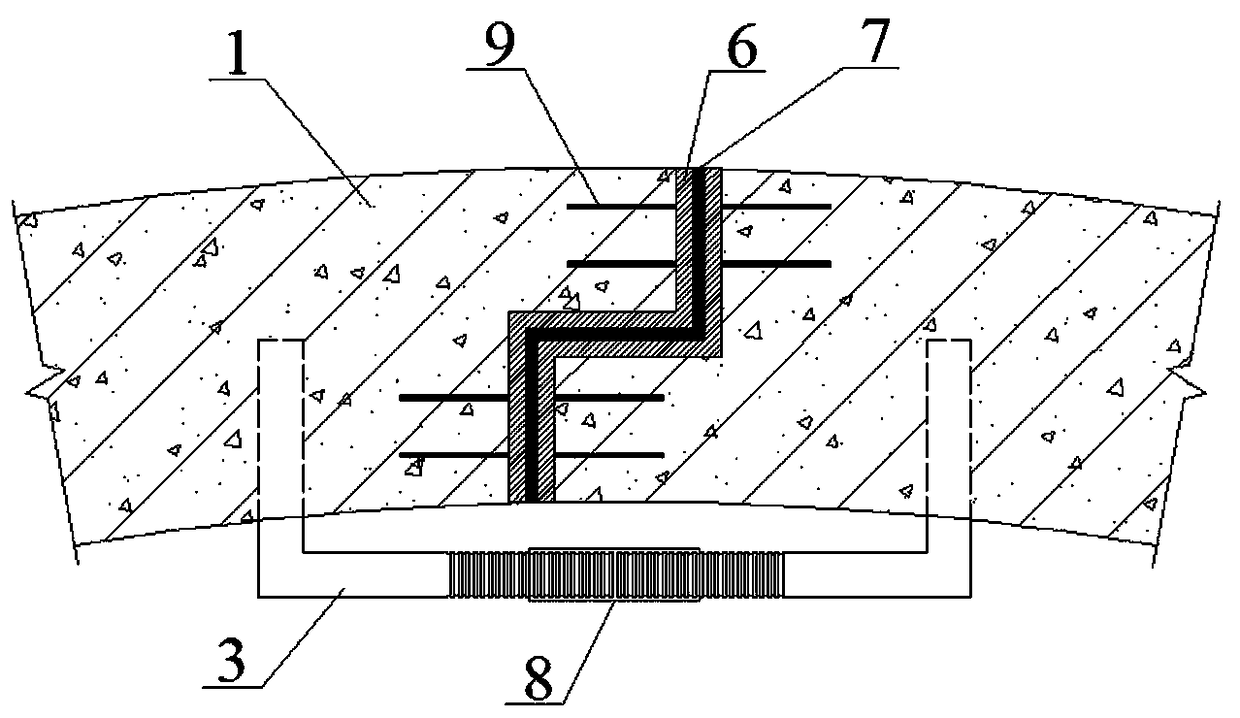

[0028] like Figure 1-4 As shown, the segment joint type shield tunnel structure of the present invention is assembled from multiple sets of segment bodies 1, and the two ends and both sides of the segment body 1 are respectively processed with stepped mortise and tenon joints arranged symmetrically. Structure, on the entire step section of the stepped mortise and tenon structure, a plurality of anchoring steel bars 9 are laid with embedded steel plates 6; the ends of every two adjacent segment bodies 1 are passed through mutually matched stepped mortise and tenon joints The structure is overlapped together, and a steel plate putty waterstop 7 is provided between the overlapping contact surfaces of the ends of every two adjacent segment bodies, and the end overlapping surfaces of every two adjacent segment bodies The bottom is provided with an anchor structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com