Automobile spare tire carrier hook assembly

A spare tire rack and assembly technology, which is applied in the field of automobile spare tire rack hook assembly, can solve the problems of being stolen and the spare tire is easy to loosen, etc., and achieves the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

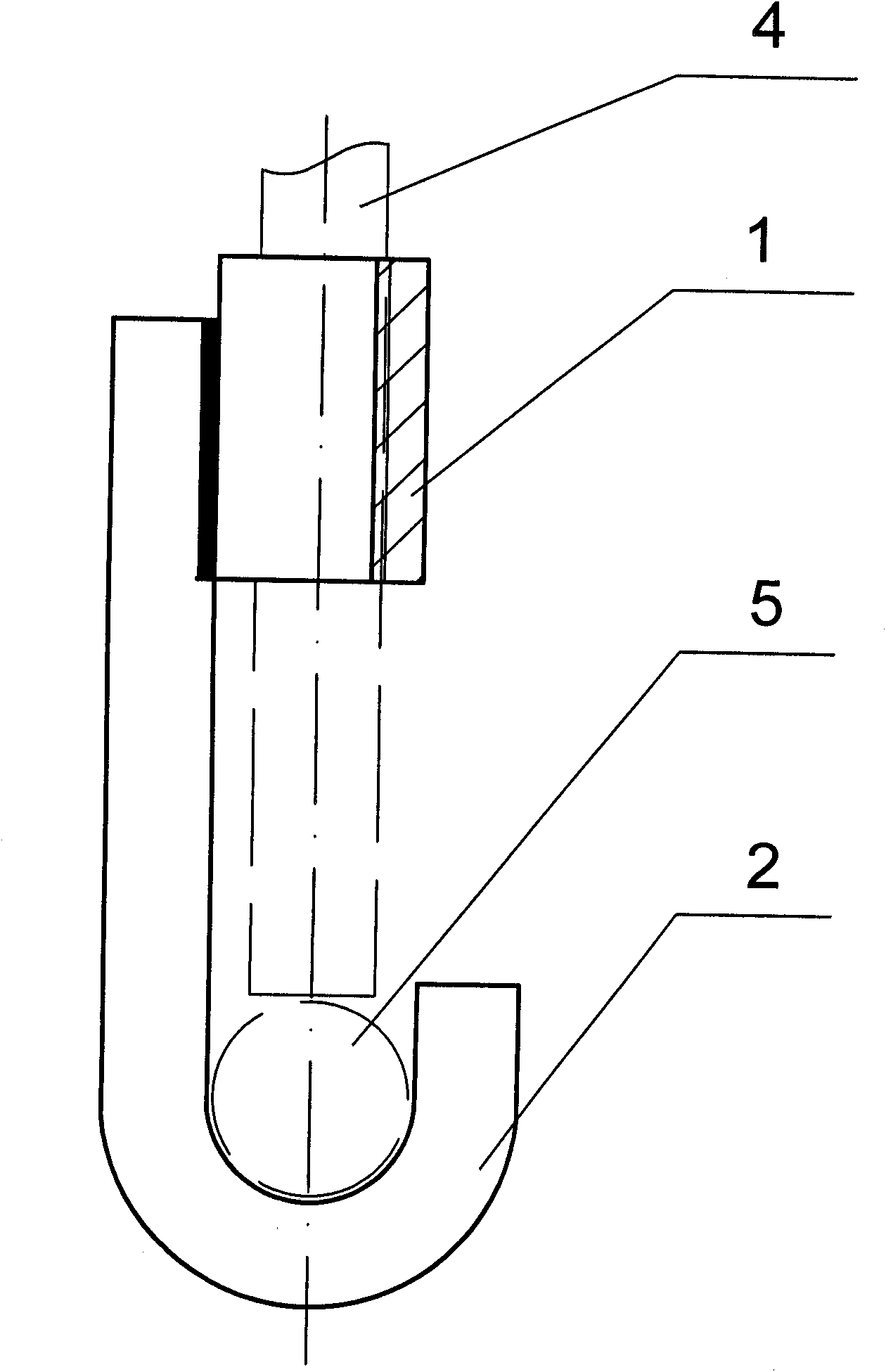

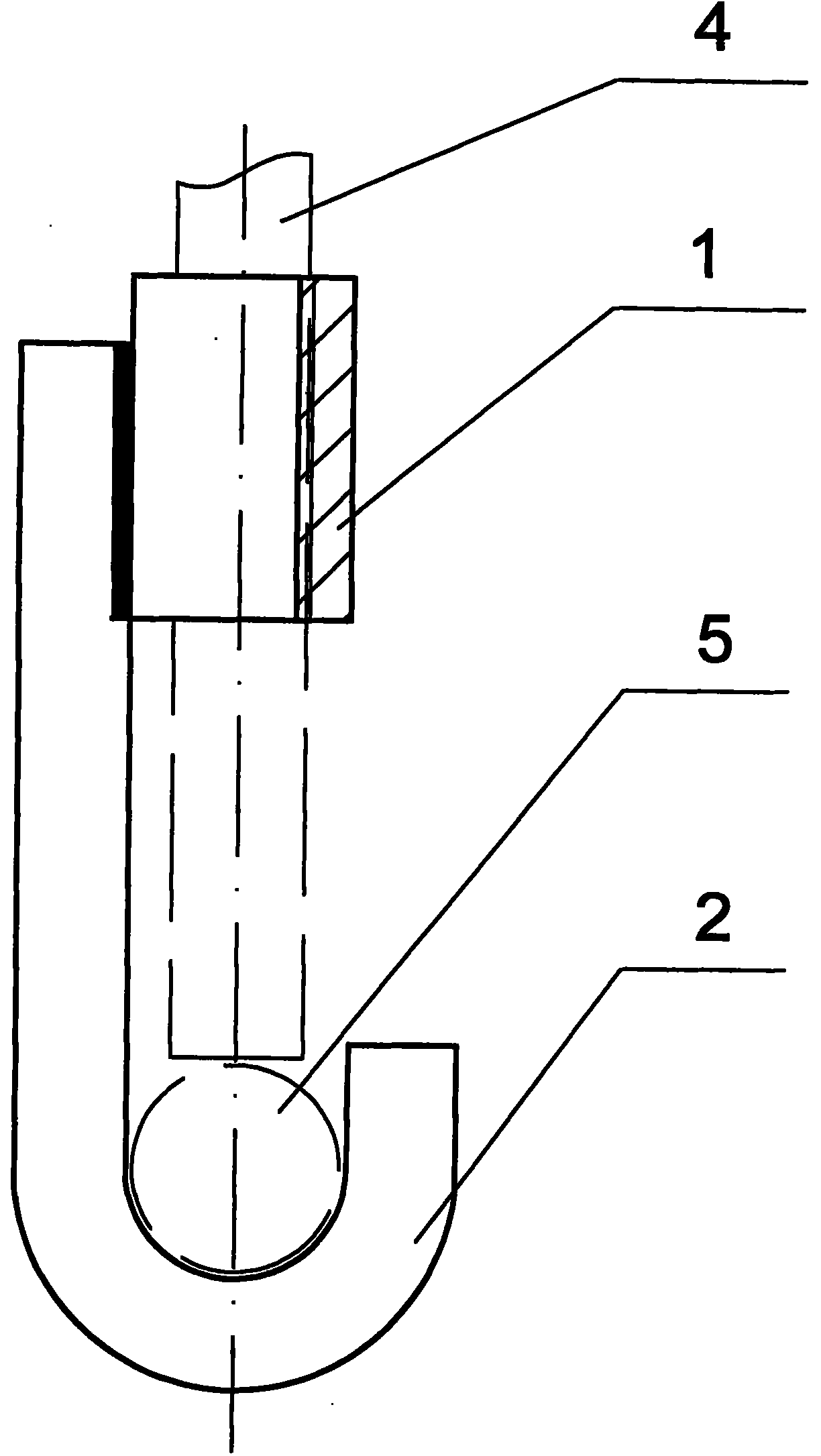

[0013] see figure 1 , the spare tire rack hook 2 of the spare tire rack hook assembly 3 is formed by bending round steel, the diameter of the bend is slightly larger than the diameter of the spare tire rack 5, and the bending depth is also greater than that of the spare tire rack 5 Diameter, so it can ensure that the assembled spare tire carrier can be accurately and firmly assembled into the hook. The bushing 1 is tapped from a round steel pipe, and the full tapping method adopted can ensure the meshing strength and orientation with the spare tire bracket bolt 4. Finally, the two are welded by a welding fixture, and the upper end of the hook 2 is welded On the outside of the sleeve pipe 1, and ensure that the center of the hook part at the lower end of the hook 2 is located on the axis extension line of the sleeve pipe 1.

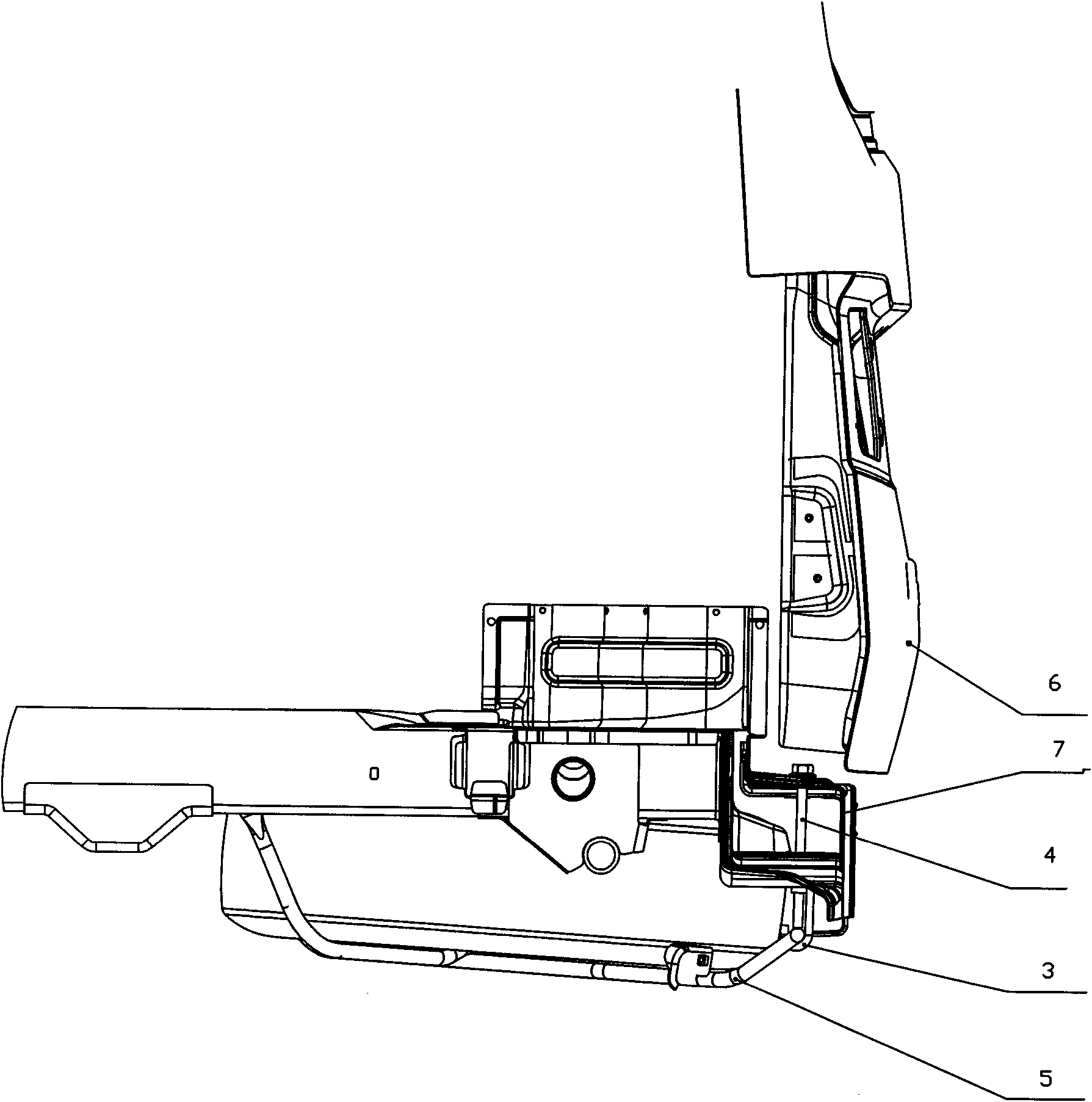

[0014] see figure 2 , when assembling, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com