Ball screw

A technology of ball screw and transmission device, which is applied in the direction of transmission device, transmission device parts, transportation and packaging, etc., and can solve the problem of troublesome relubrication of ball screw transmission device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

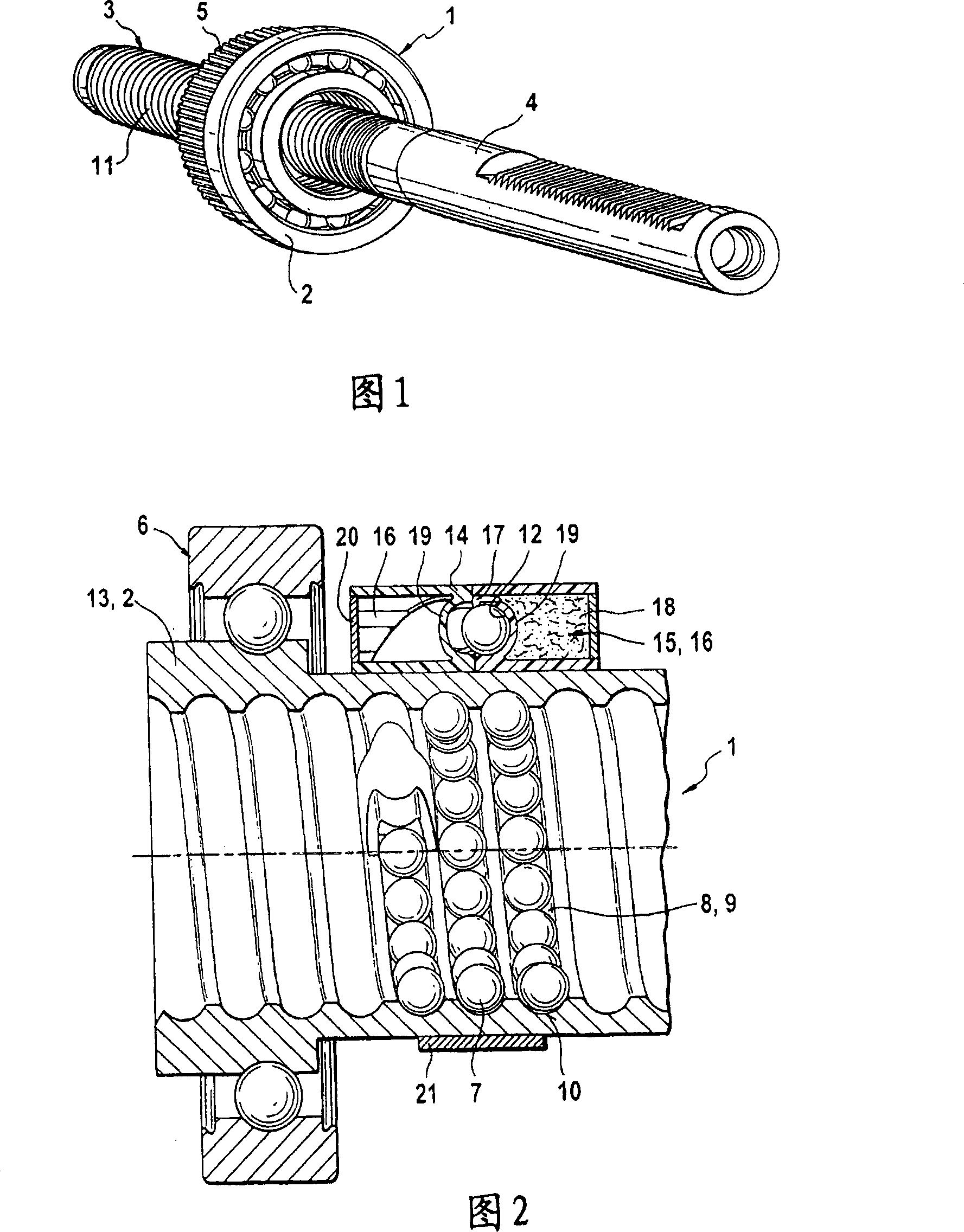

[0018] FIG. 1 shows the main components of a power-assisted rack and pinion steering of a motor vehicle in a perspective view. A ball screw drive 1 has a spindle nut 2 which is rotatably mounted on a ball screw 3 . The ball screw 3 is formed purely as an axial extension of the toothed rack. It can also be seen from FIG. 1 that the spindle nut 2 is equipped with a drive pinion 5 for a toothed belt (not shown here). This drive pinion 5 is connected to the spindle nut 2 in a rotationally fixed manner.

[0019] The spindle nut is installed here in a housing which is not further shown here.

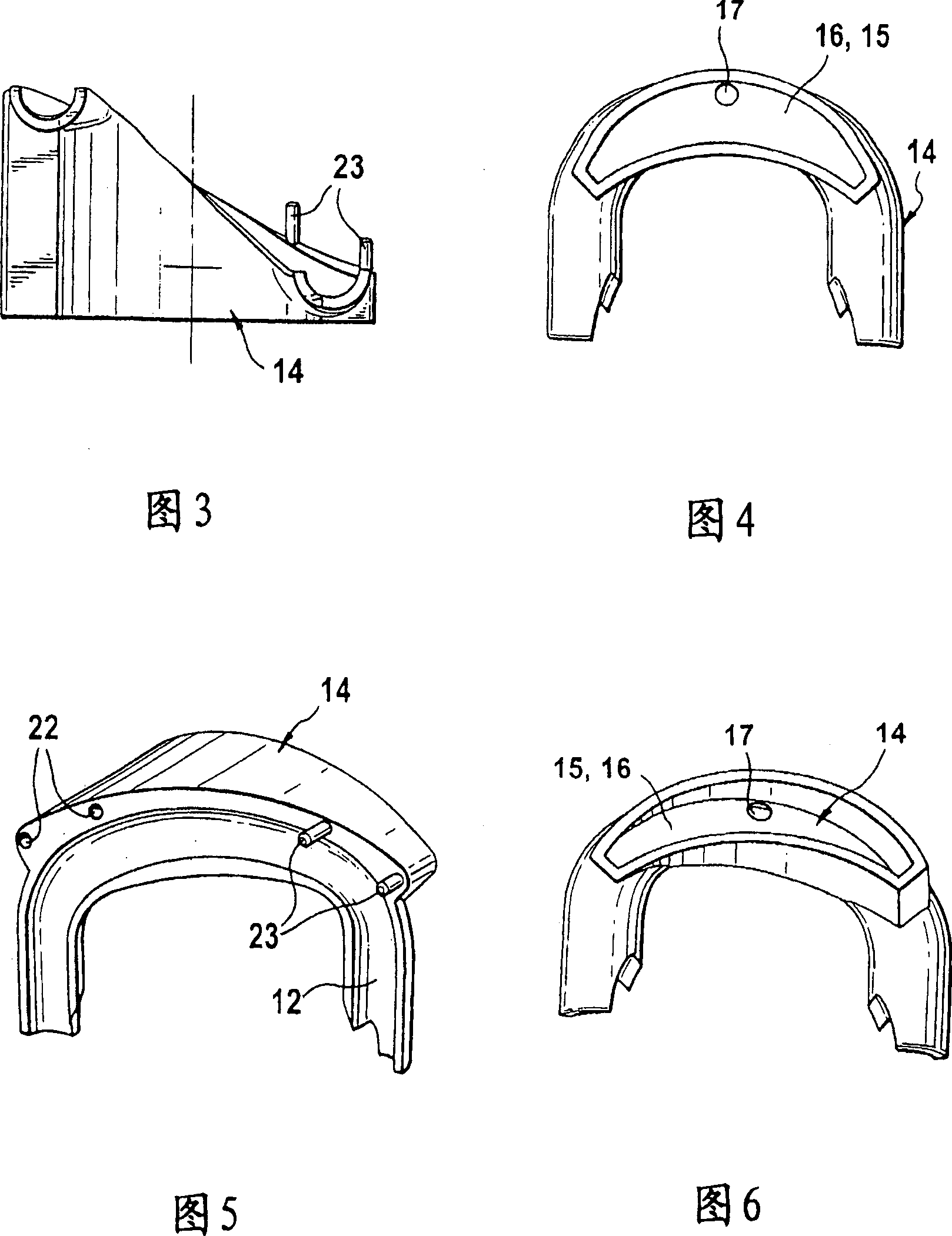

[0020] FIG. 2 shows a longitudinal sectional view of the ball screw drive 1 in an enlarged view. The spindle nut 2 is mounted rotatably via deep-groove ball bearings 6 in a housing (not shown here). The balls 7 can be arranged continuously around in the continuous ball channel 8 . This continuous ball channel 8 has a load section 9 which is delimited by the ball raceways 10 , 11 of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com