Computer-aided technique planning method for silicon micro-component

A computer-aided and process planning technology, applied in computing, instruments, special data processing applications, etc., can solve problems such as lack of intuition, high requirements for designers’ process knowledge, and no systematic summary of 3D manufacturing characteristics of micro devices. Achieve fewer iterations, fewer counts, fewer etch and photolithography steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and the examples completed by the inventor according to the technical solution of the present invention. 5. Contents of the invention

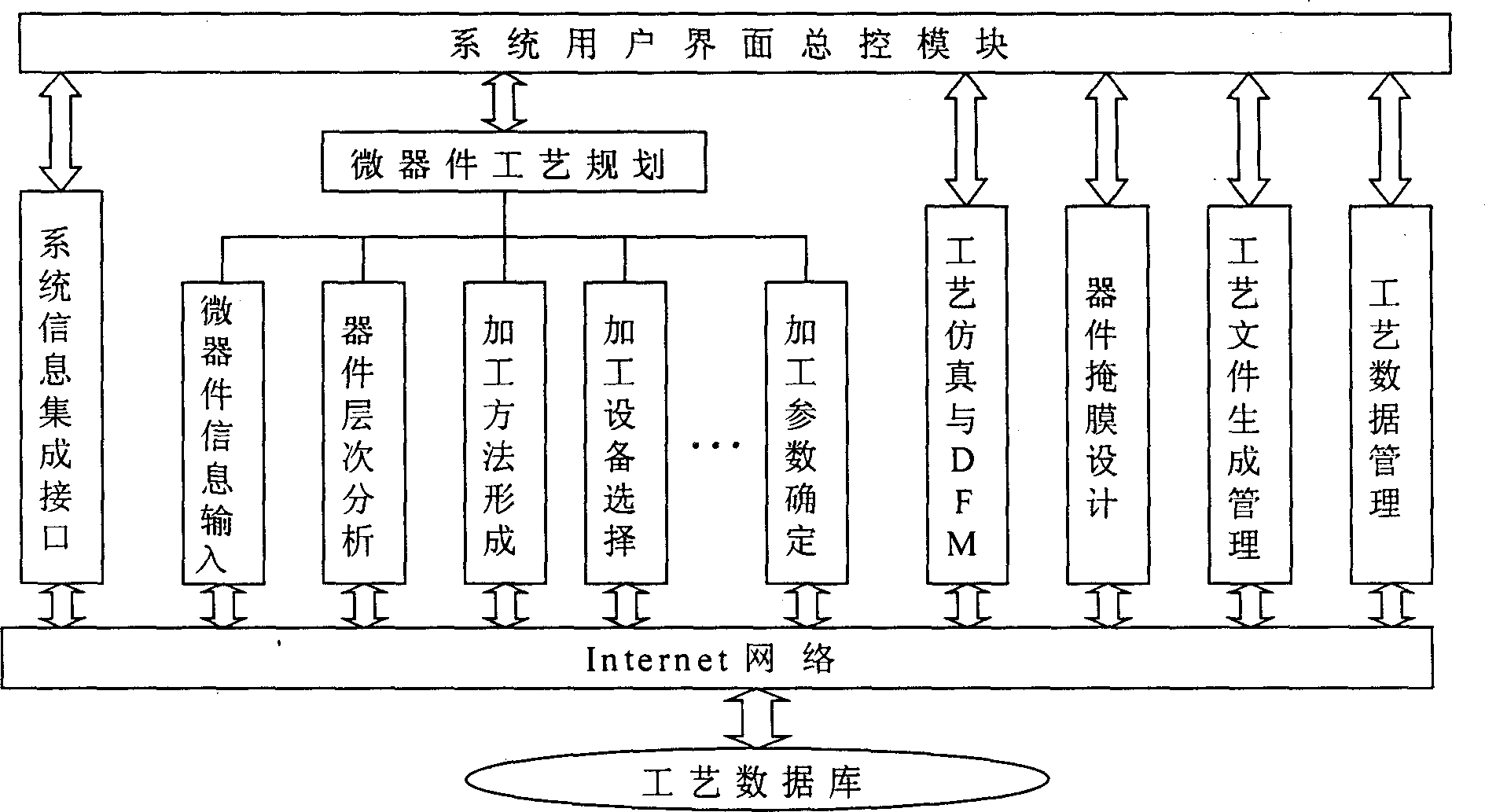

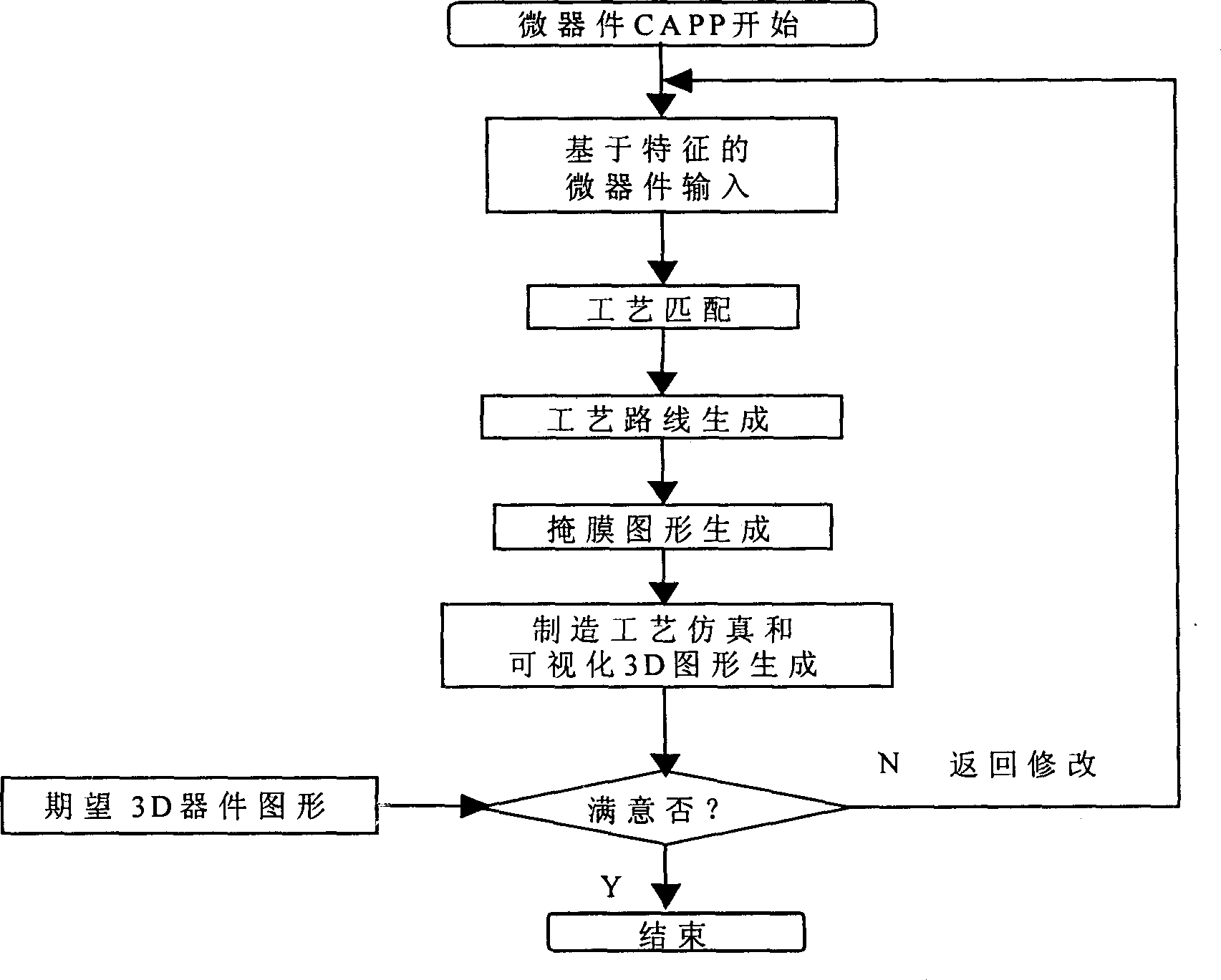

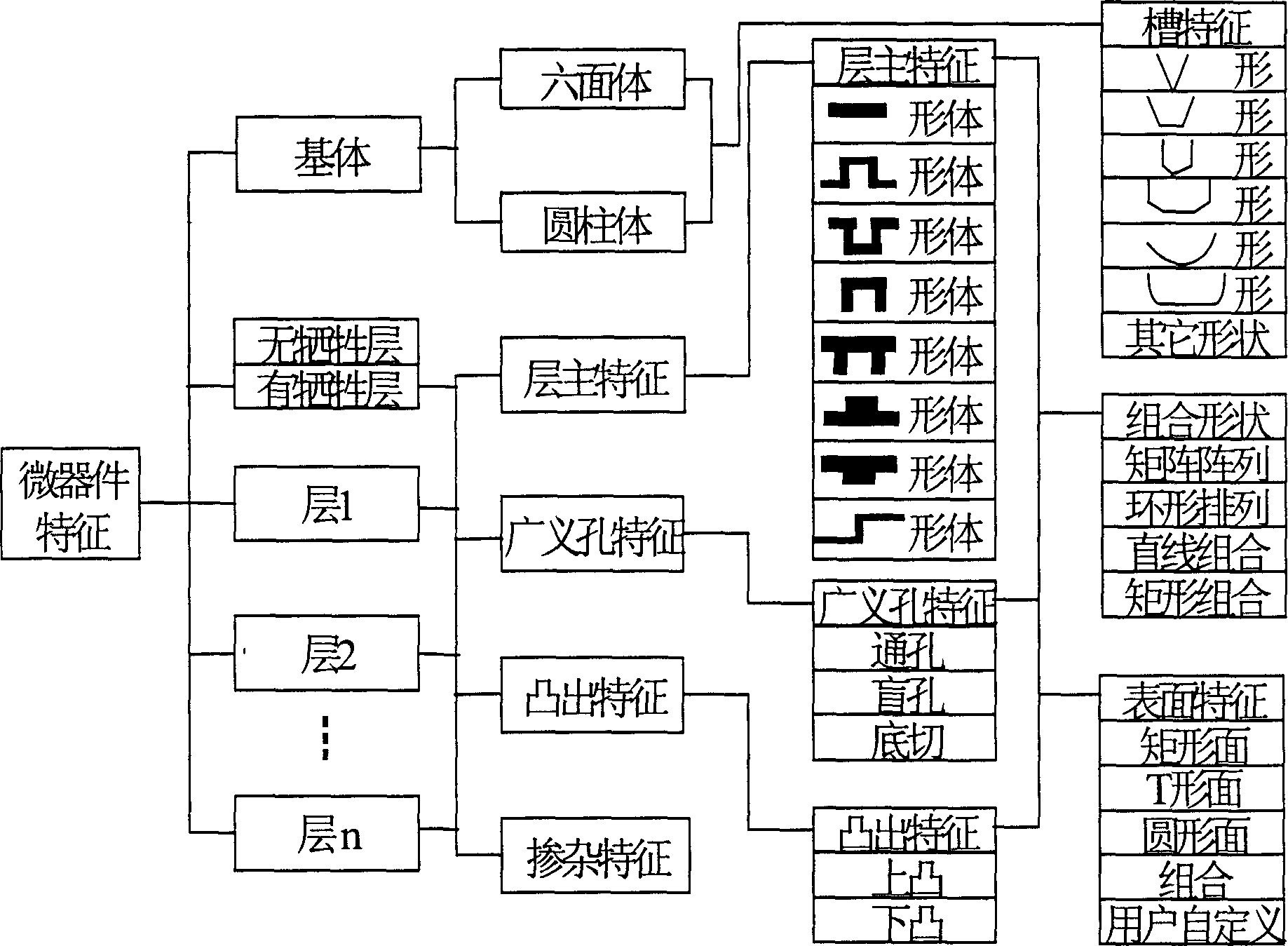

[0034] The method of the present invention is to decompose the three-dimensional geometric structure of the micro-device according to the processing layer, each layer is composed of layer main features and several auxiliary features, and a complete three-dimensional and two-dimensional surface manufacturing feature of the micro-device is established. The micromachining method is linked and reflects the constraints of the micromachining process. The relationship between MEMS layout and mask and micromachining process design is established. With a given 3D micro-device model, the system merges the main features of the micro-device hierarchically, reducing the number of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com