Grease composition

A technology of lubricating grease composition and urea compound, which is applied in the direction of lubricating composition, base material, thickener, etc., can solve the problems of not being able to deal with peeling, not preventing it, etc., and achieve the purpose of inhibiting white layer peeling, prolonging bearing lubrication life, prolonging Effect of peel life

Active Publication Date: 2016-04-13

KYODO YUSHI CO LTD +1

View PDF24 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0127]

[0128] · Preparation of test grease

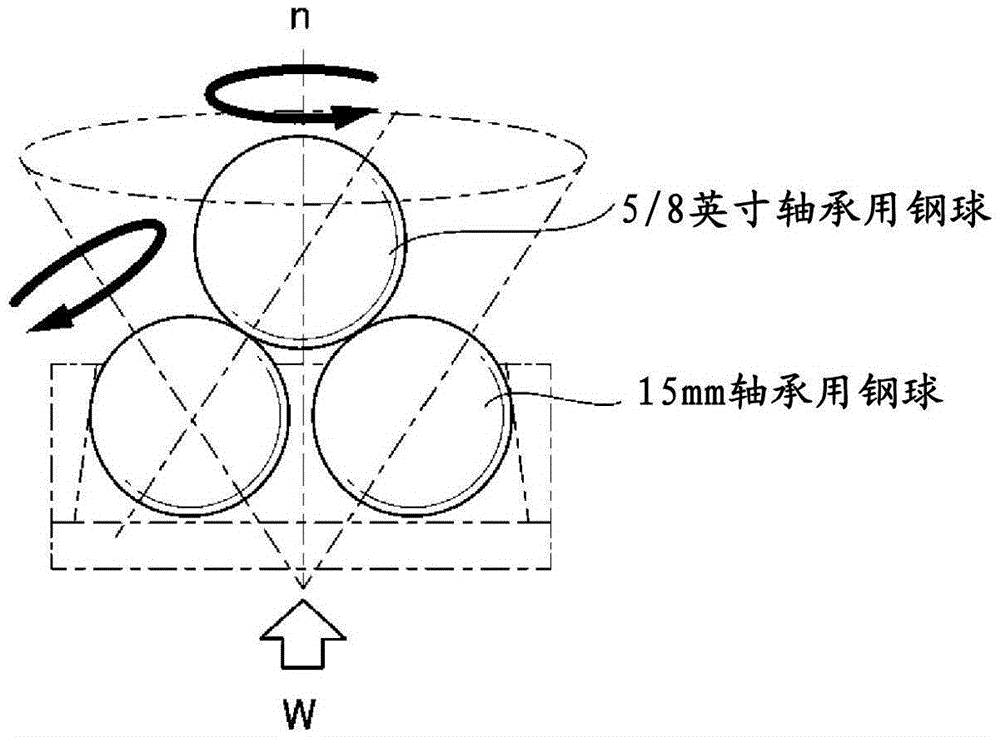

[0129] Base grease is obtained by reacting diphenylmethane diisocyanate with a specified amount of amines (octylamine, cyclohexylamine, octadecylamine, p-toluidine) in base oil, adding base oil and additives, Grinding treatment was performed so that the mixing consistency was 280 (JIS K2220), and a grease was prepared.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

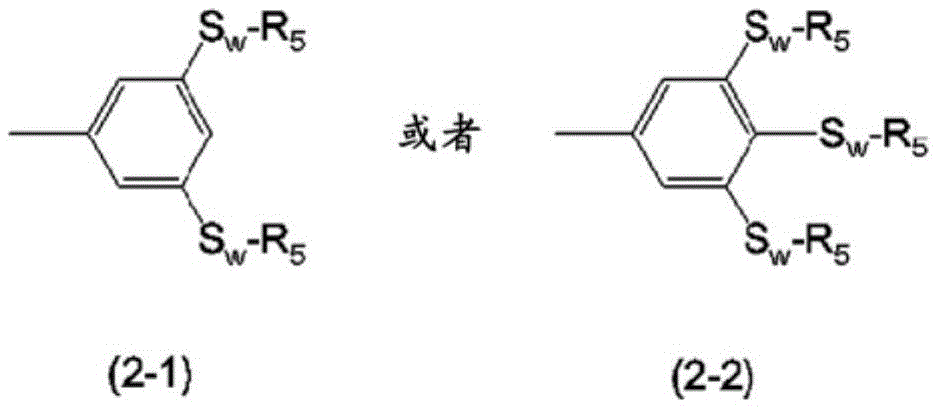

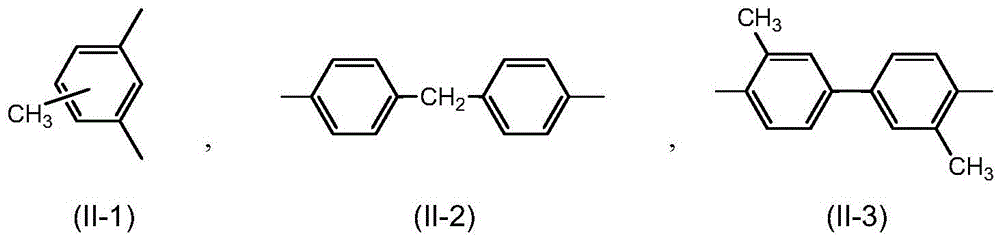

The present invention provides a grease composition which contains a base oil, a thickening agent and an anti-flaking additive such as a compound represented by, for example, formula (1-1), and which suppresses white layer flaking in a rolling bearing. (In the formula, R1 and R4 are each independently a straight chain or branched chain alkyl or alkenyl group having 1-20 carbon atoms.)

Description

technical field [0001] The present invention relates to a grease composition for suppressing white layer exfoliation of rolling bearings. Background technique [0002] Responding to the demand for smaller, lighter and more usable space in automobiles, it is necessary to reduce the space in the engine compartment. Along with this demand, electrical appliances such as alternators and tensioners, and auxiliary parts are also required to be smaller and lighter. In addition, the engine room is sealed for quietness, and the operating environment becomes high temperature. Therefore, a grease that can withstand high temperature is required. [0003] In addition, in order to reduce the diameter of the pulley, increase the transmission torque, and improve the durability of the belt, since the mid-1980s, multi-V belts have been gradually adopted. Since then, there have been occurrences on the rolling surface of rolling bearings. Specific early abnormal peeling problem with white tissu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M135/04C10M135/06C10M135/22C10M135/28C10M135/34C10M135/36C10M169/00C10M169/04C10M169/06C10M101/02C10M105/18C10M105/32C10M115/08C10N30/00C10N40/02C10N50/10

CPCC10M135/36C10M2215/1026C10M2219/022C10M2219/024C10M2219/082C10M2219/086C10M2219/102C10M2219/106C10N2030/06C10N2040/02C10N2050/10C10M101/02C10M105/04C10M105/18C10M105/42C10M115/08C10M135/04C10M135/06C10M169/00

Inventor 吉成照小森谷智延广冈岩树武藤正誉中泽圣福岛由伦森诚之

Owner KYODO YUSHI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com