Chemical copper stripping potion and copper stripping method

A chemical and potion technology, applied in the field of chemical copper stripping potion and copper stripping of electroplating clamps, can solve the problems of environmental impact, easy decomposition of hydrogen peroxide, health hazards of employees, etc., and achieve the effect of accelerating stripping and prolonging stripping life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a chemical copper stripping potion and a copper stripping method.

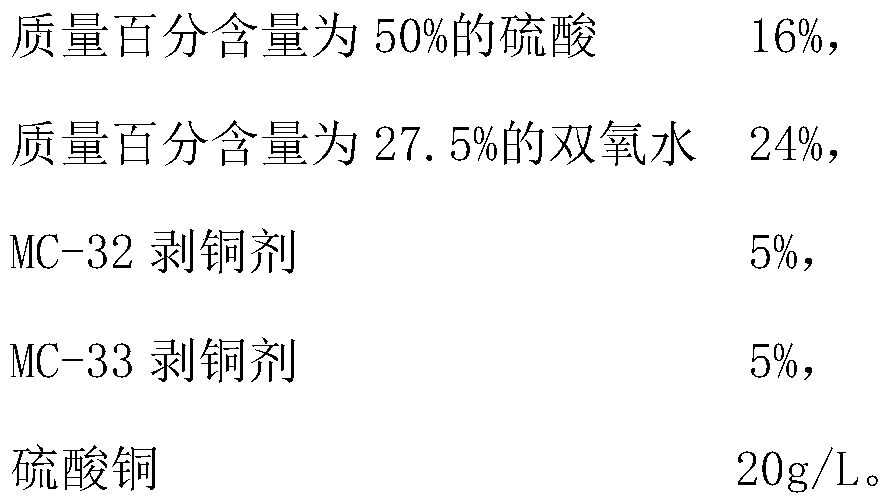

[0027] The formula of the chemical copper stripping potion is shown in Table 1. The formula is to add the following substances at the final concentration in the water:

[0028]

[0029] The stripping method comprises the steps:

[0030] (1) prepare the chemical copper stripping potion according to the formula in Table 1 in the frying stick groove;

[0031] (2) Carry out copper stripping treatment on the electroplating clamp rod by vertical immersion, the temperature of the chemical copper stripping solution is 50±2°C during the treatment process, and the supplementary amount of the chemical copper stripping solution is 16L every 40min;

[0032] (3) When Cu in the chemical copper stripping potion 2+ When the concentration reaches 55g / L, replace the chemical copper stripping solution in the deep frying tank.

[0033] In this embodiment, the time for copper stripping of the e...

Embodiment 2

[0035] This embodiment provides a chemical copper stripping potion and a copper stripping method.

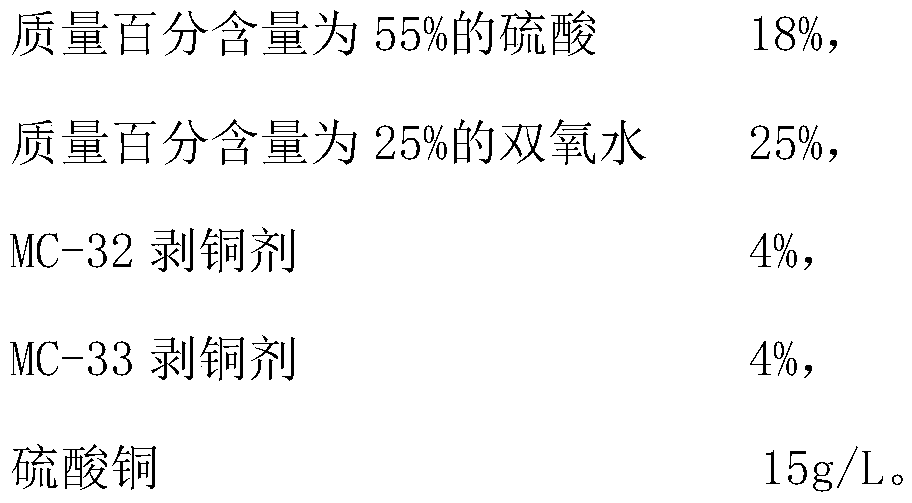

[0036] The formula of the chemical copper stripping potion is shown in Table 1. The formula is to add the following substances at the final concentration in the water:

[0037]

[0038] The stripping method comprises the steps:

[0039] (1) prepare the chemical copper stripping potion according to the formula in Table 1 in the frying stick groove;

[0040] (2) Carry out copper stripping treatment on the electroplating clamp bar by horizontal spraying, the temperature of the chemical copper stripping potion is 50±2°C during the treatment process, and the supplementary amount of the chemical copper stripping potion is 20L every 40min;

[0041] (3) When Cu in the chemical copper stripping potion 2+ When the concentration reaches 55g / L, replace the chemical copper stripping solution in the deep frying tank.

[0042] It takes 68 seconds for the electroplating clamp bar to carry...

Embodiment 3

[0044] This embodiment provides a chemical copper stripping potion and a copper stripping method.

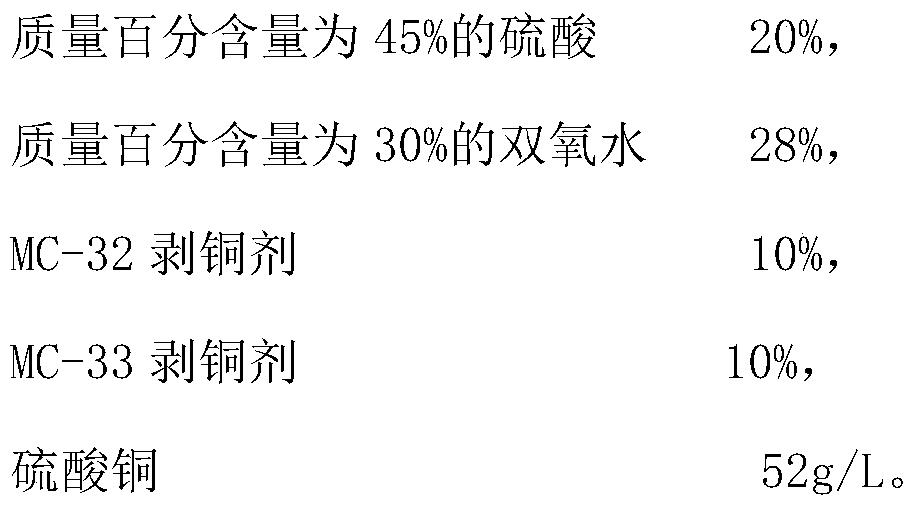

[0045] The formula of the chemical copper stripping potion is shown in Table 1. The formula is to add the following substances at the final concentration in the water:

[0046]

[0047] The stripping method comprises the steps:

[0048] (1) prepare the chemical copper stripping potion according to the formula in Table 1 in the frying stick groove;

[0049] (2) Carry out copper stripping treatment on the electroplating clamp rod by means of horizontal spraying, the temperature of the chemical copper stripping potion is 50±2°C during the treatment process, and the supplementary amount of the chemical copper stripping potion is 29L every 40min;

[0050] (3) When Cu in the chemical copper stripping potion 2+ When the concentration reaches 55g / L, replace the chemical copper stripping solution in the deep frying tank.

[0051] It takes 68 seconds for the electroplating clamp bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com