Membrane-grease composite lubrication method

A technology of lubricating grease and lubricating film, used in engine lubrication, gear lubrication/cooling, belt/chain/gear, etc. Working conditions and other problems, to achieve the effect of good lubrication effect and prolong lubrication life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

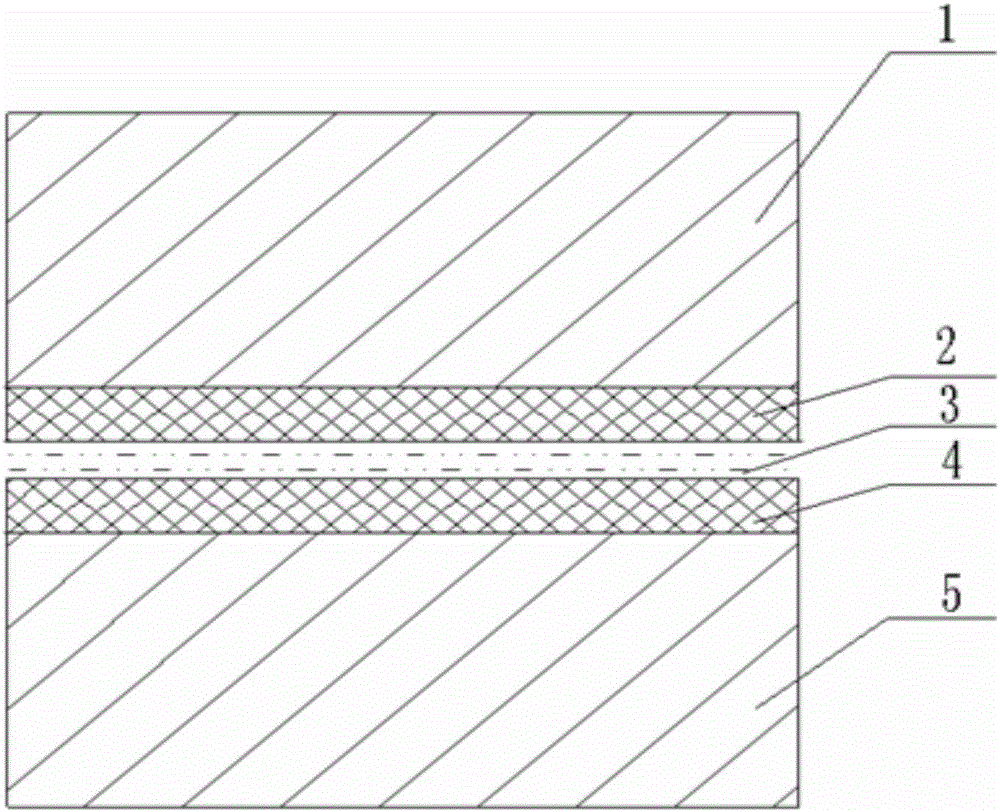

[0026] Specific embodiment 1: This embodiment is a film-grease composite lubrication method, the process is as follows: the surface of the workpiece is pretreated, then a solid lubricating film is processed on the surface of the workpiece, and then grease is coated on the surface of the solid lubricating film or on the solid lubrication Grease is injected into the friction interface of the membrane to complete the membrane-grease compound lubrication;

[0027] The solid lubricating film is a composite film composed of one or more of a soft metal film, a polymer material film, a layered structure material film, and a ceramic film; the soft metal film is gold, silver, lead, tin or indium The polymer material film is nylon, polytetrafluoroethylene or polyimide; the layered material film is graphite, molybdenum disulfide, tungsten disulfide or boron nitride; the ceramic film is Al 2 O 3 , ZrO 2 , Si 3 N 4 , SiC, TiO 2 , WC or Cr 2 O 3 The grease is a composite titanium-based grease, a...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment is different from Embodiment 1 in that the workpiece surface is a gear tooth surface, a bearing ball surface, a bearing inner ring surface, or a bearing outer ring surface. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that the method for preparing the soft metal film is an ion plating method or an ion implantation method. Other steps and parameters are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com