Water-resistant extreme pressure lithium lubricating grease and preparation method thereof

A lithium-based grease, water-resistant technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of low drop point of water-resistant grease, poor water-scouring resistance, poor mechanical stability, etc., and shorten the saponification. Dehydration time, not easy to soften and lose, good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

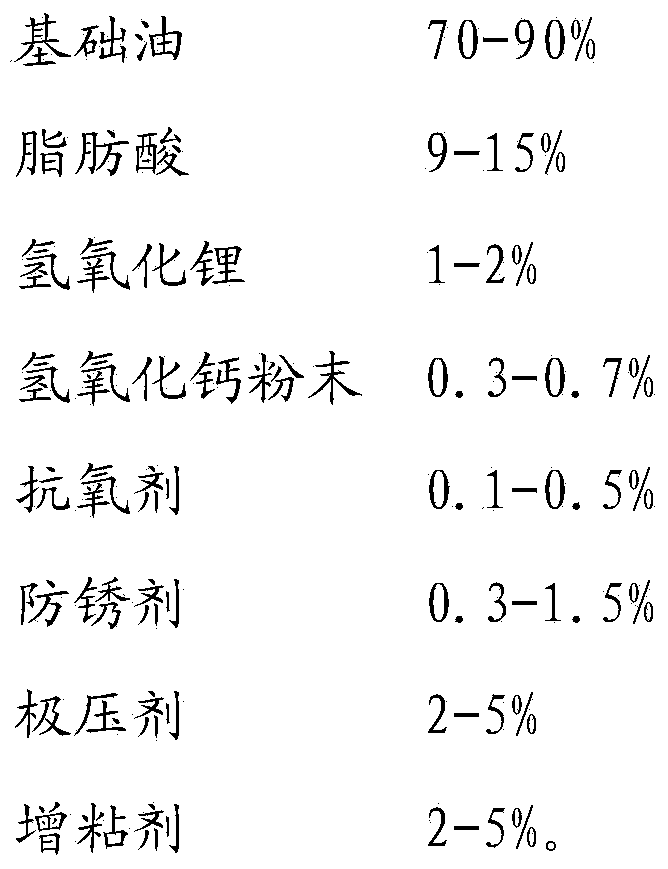

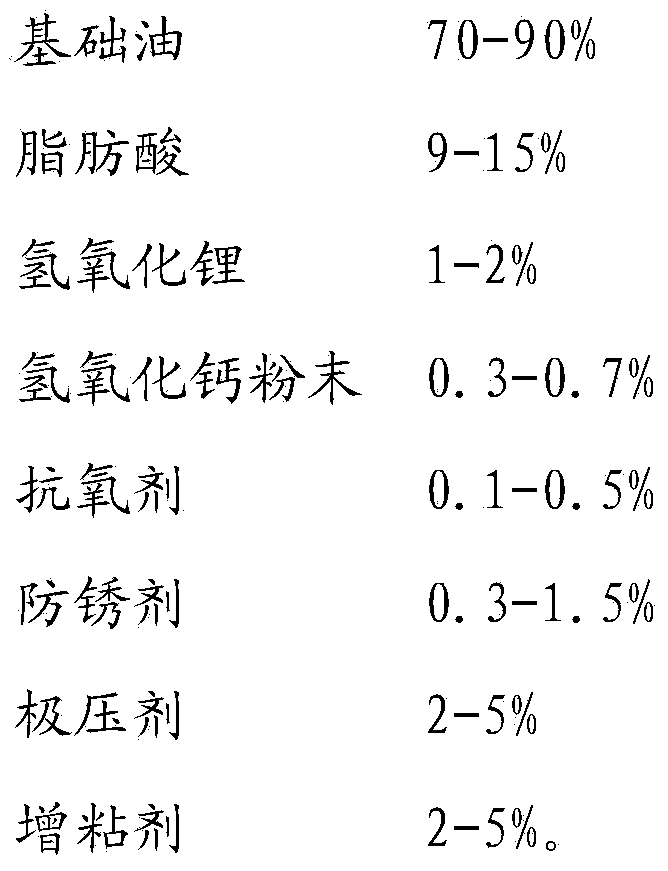

Method used

Image

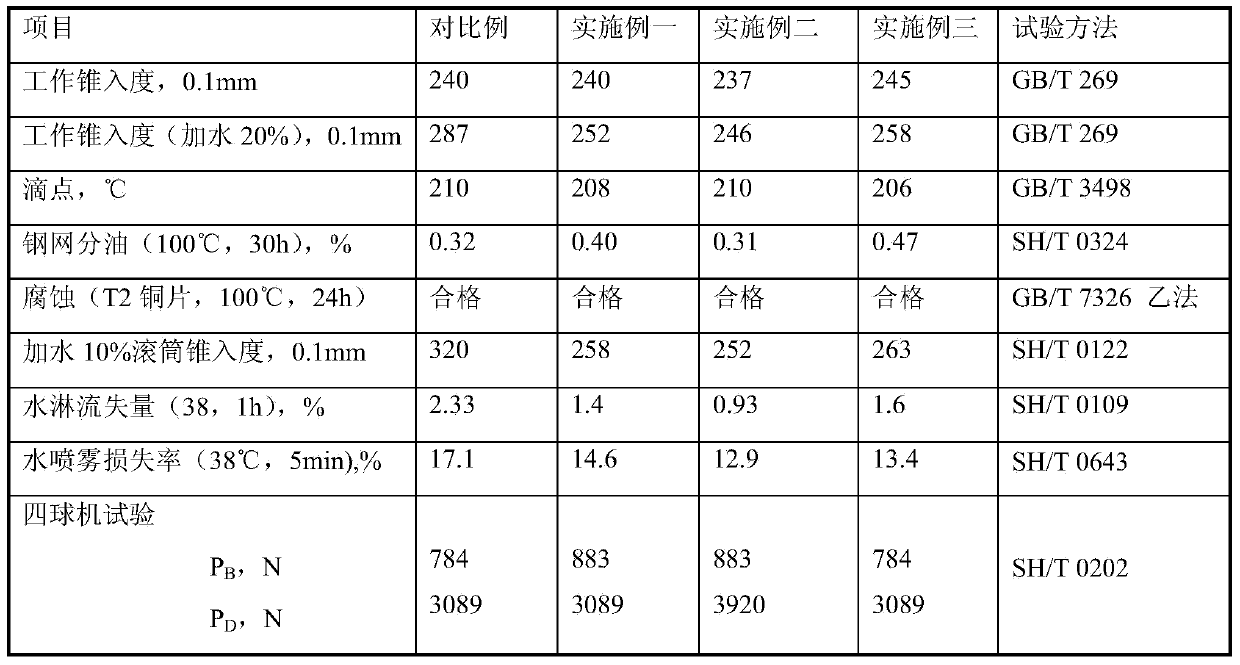

Examples

Embodiment 1

[0025] In this embodiment, the raw materials are prepared according to the following method for water-resistant extreme pressure lithium-based grease:

[0026] Step 1: Add 1500kg of base oil 500SN (kinematic viscosity at 40°C to 92mm 2 / s), 375kg of 12-hydroxystearic acid and 93kg of stearic acid were put into the saponification tank in sequence, and the stirring was started and the temperature was raised to 80°C to dissolve all the fatty acids;

[0027] Step 2: add a solution of 54kg lithium hydroxide dissolved in 250kg water, and heat up to 105°C, and saponify for 60min;

[0028] Step 3: Continue to raise the temperature to 165°C, add 11.2kg of calcium hydroxide powder, and stir for 35 minutes to react, then raise the temperature to 210°C for high-temperature refining, and keep warm for 3 minutes;

[0029] Step 4: Add 1200kg of base oil 500SN to the saponification kettle, quench the material to 170°C, then transfer to the blending kettle, circulate and filter, add the remai...

Embodiment 2

[0032] In this embodiment, the raw materials are prepared according to the following method for water-resistant extreme pressure lithium-based grease (the base oil used in this embodiment is 500SN and L-AN100, and the kinematic viscosity at 40°C after mixing is 110mm 2 / s):

[0033] Step 1: Put 1600kg of the above-mentioned mixed base oil and 450kg of 12-hydroxystearic acid into the saponification tank in sequence, start stirring and heat up to 85°C to dissolve all the fatty acids;

[0034] Step 2: Add a solution of 53kg lithium hydroxide dissolved in 300kg water, and heat up to 110°C, saponification reaction for 45min;

[0035] Step 3: Continue to heat up to 170°C, add 14kg of calcium hydroxide powder, and stir for 45 minutes to react, then heat up to 215°C for high-temperature refining, and keep warm for 5 minutes;

[0036] Step 4: Add 1200kg of the above-mentioned mixed base oil into the saponification kettle, quench the material to 175°C, then transfer it to the blending ...

Embodiment 3

[0039] In this embodiment, the raw materials are prepared according to the following method to prepare water-resistant extreme pressure lithium-based grease (the base oils selected in this embodiment are 400SN and 150BS, and the kinematic viscosity at 40°C after mixing is 160mm 2 / s):

[0040] Step 1: put 1500kg of the above-mentioned mixed base oil and 445kg of 12-hydroxystearic acid into the saponification tank in turn, start stirring and raise the temperature to 82°C to dissolve all the fatty acids;

[0041] Step 2: add a solution of 55kg lithium hydroxide dissolved in 300kg water, and heat up to 105°C, saponification reaction for 60min;

[0042] Step 3: Continue to heat up to 165°C, add 12.4kg of calcium hydroxide powder, and stir for 30 minutes to react, then heat up to 210°C for high-temperature refining, and keep warm for 3 minutes;

[0043] Step 4: Add 1200kg of the above-mentioned mixed base oil into the saponification kettle, quench the material to 175°C, then trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com