Composite lithium-calcium-based lubricating grease and preparation method

A technology of calcium-based grease and lithium complex, which can be used in lubricating compositions, petroleum industry, additives, etc., and can solve the problems of limiting the application of lithium-calcium complex grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

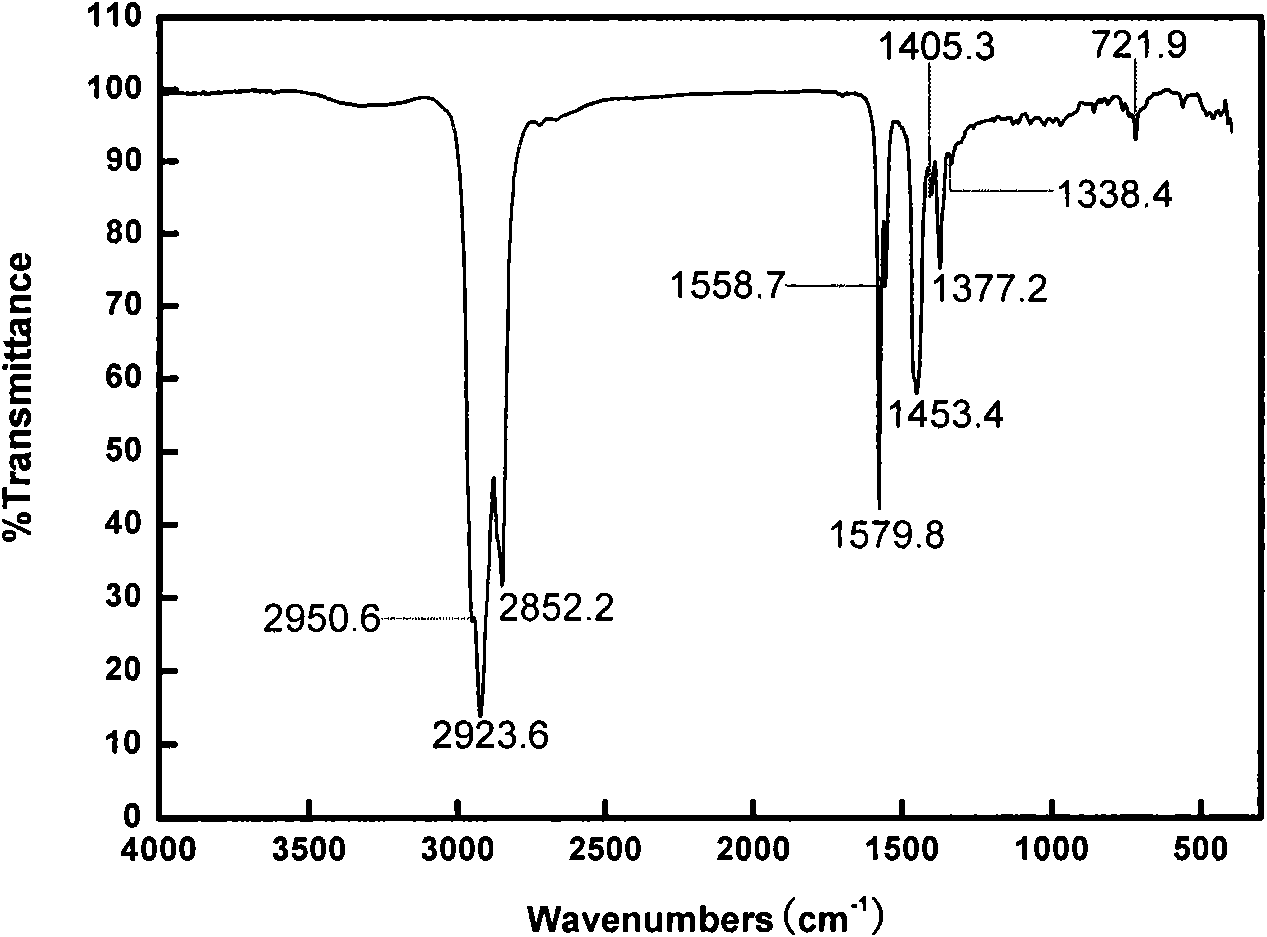

[0038] Embodiment 1, the preparation of the complex lithium-calcium base lubricating grease that is made up of reducing second-line base oil, complex lithium-calcium base thickener, surfactant and additive

[0039] Using naphthenic base oil (at 100°C, the kinematic viscosity is 8.01mm 2 / s) as a grease base oil. Get the 12-hydroxystearic acid of 50g, 200g naphthenic base oil, the lime emulsion that contains 2.2g calcium hydroxide and 2g cetyltrimethylammonium bromide drop in reactor, stir and gradually heat up, Rise to 95°C for 2 hours at a constant temperature. At this time, part of the 12-hydroxystearic acid and calcium hydroxide undergoes a saponification reaction. Then 12.5g of sebacic acid and 2.5g of boric acid were put into the reaction kettle, and after fully stirring for 10 minutes, the temperature was raised to 120°C, and the heated 10% aqueous solution containing 13.5g of lithium hydroxide monohydrate was added, and then saponified for 2 hours. Water can be added...

Embodiment 2

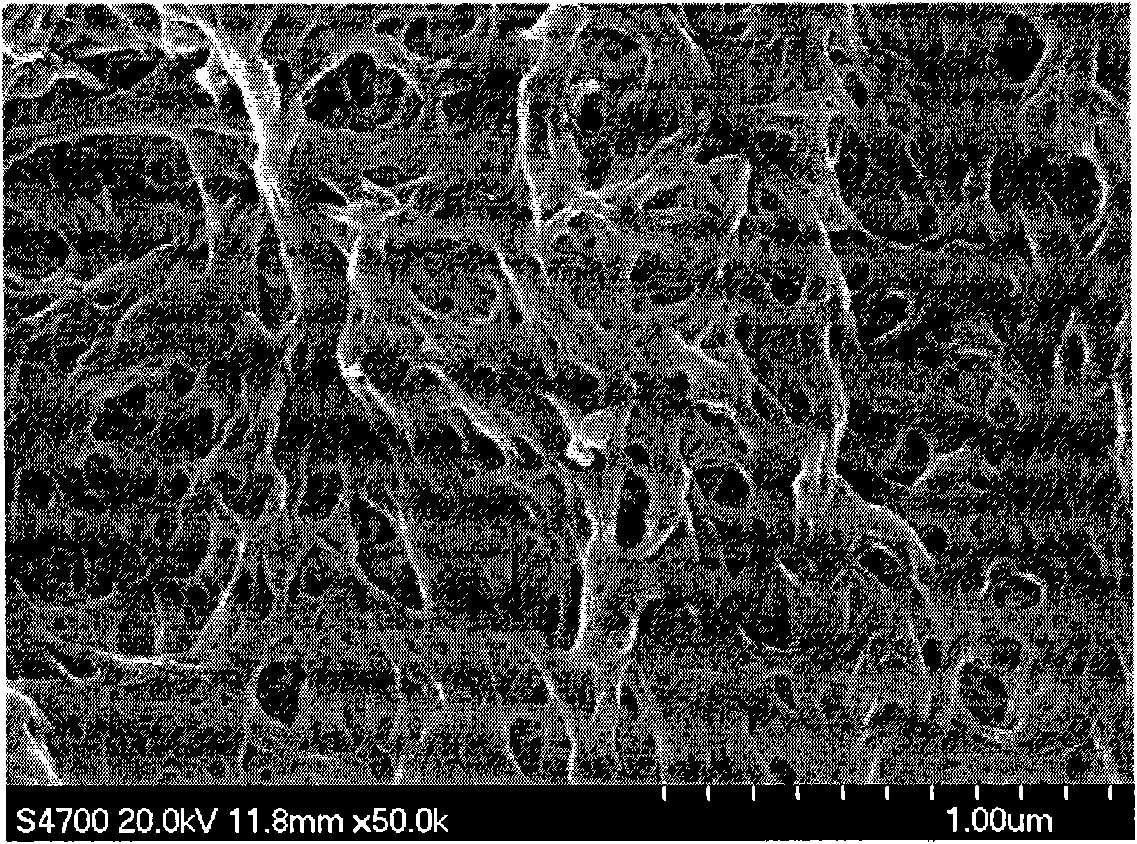

[0040] Embodiment 2, the preparation of the complex lithium-calcium base lubricating grease that is made up of three-line base oil, complex lithium-calcium base thickener, surfactant and additive

[0041] Using naphthenic base oil minus the third line (at 100°C, the kinematic viscosity is 19.98mm 2 / s) as a grease base oil. Get the 12-hydroxystearic acid of 50g, 200g naphthenic base oil minus three lines, the lime emulsion that contains 2.2g calcium hydroxide and 2g cetyltrimethylammonium bromide drop in reactor, stir and gradually heat up, Rising to 98°C for 1 hour constant temperature reaction. At this time, part of the 12-hydroxystearic acid and calcium hydroxide undergoes a saponification reaction. Then 12.5g of sebacic acid and 2.5g of boric acid were put into the reaction kettle, and after fully stirring for 10 minutes, the temperature was raised to 123°C, and the heated 10% aqueous solution containing 13.5g of lithium hydroxide monohydrate was added, and then saponifi...

Embodiment 3

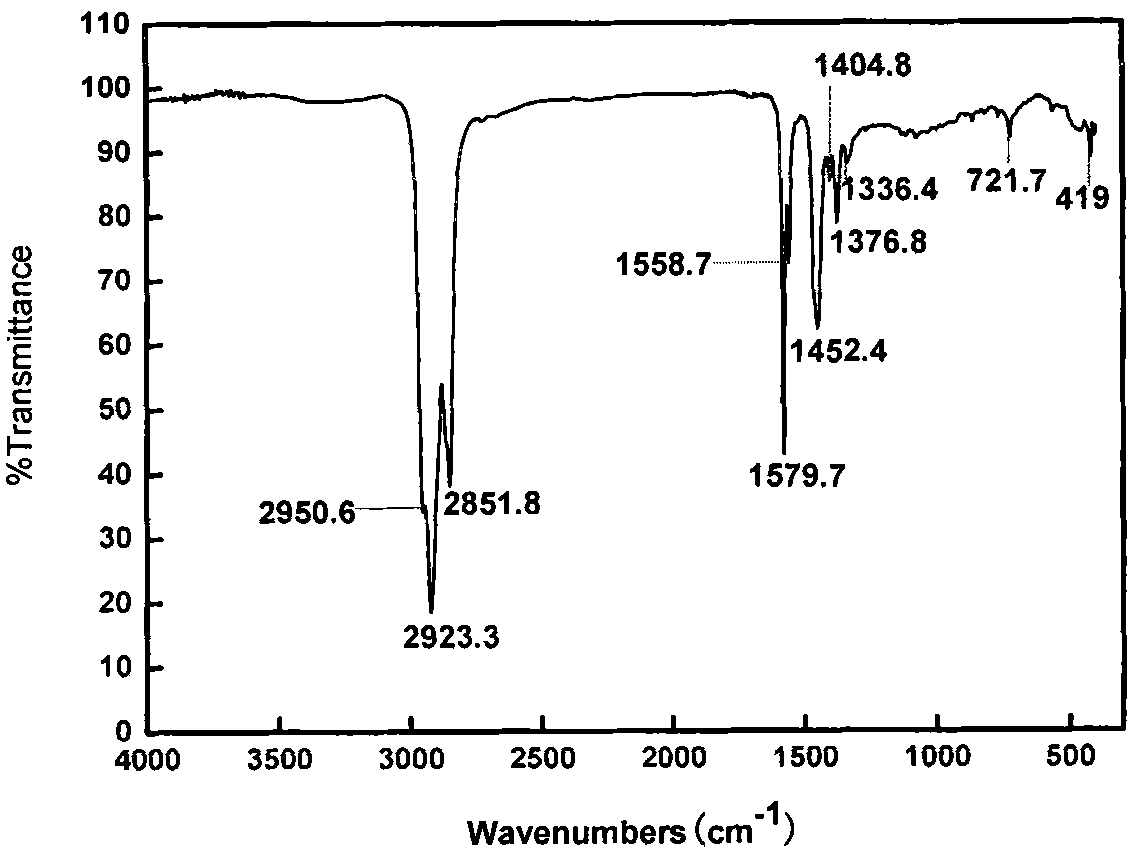

[0042] Embodiment 3, the preparation of the complex lithium-calcium base lubricating grease that is made up of minus four line base oil, complex lithium-calcium base thickener, surfactant and additive

[0043] Use naphthenic base oil minus four lines (at 100°C, the kinematic viscosity is 25.46mm 2 / s) as a grease base oil. Get 50g of 12-hydroxystearic acid, 250g naphthenic base oil and contain 2.2g calcium hydroxide, lime emulsion and 2g ditetradecyl dimethyl ammonium bromide and drop into the reactor, stir and gradually The temperature was raised to 101° C. for a constant temperature reaction for 2 hours. Then 12.5g of azelaic acid and 2.5g of boric acid were put into the reaction kettle, and after fully stirring for 10 minutes, the temperature was raised to 125°C, and a heated 10% aqueous solution containing 13.5g of lithium hydroxide monohydrate was added, and then saponified for 3 hours. Water can be added appropriately. After saponification, the temperature is raised t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com