Environment-friendly lubricating grease and preparation method thereof

An environmentally friendly, grease technology, applied in lubricating compositions, petroleum industry, base materials, etc., can solve the problem of low degradation rate of grease, achieve good environmental friendliness, improved oxidation stability, and excellent conventional physical and chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

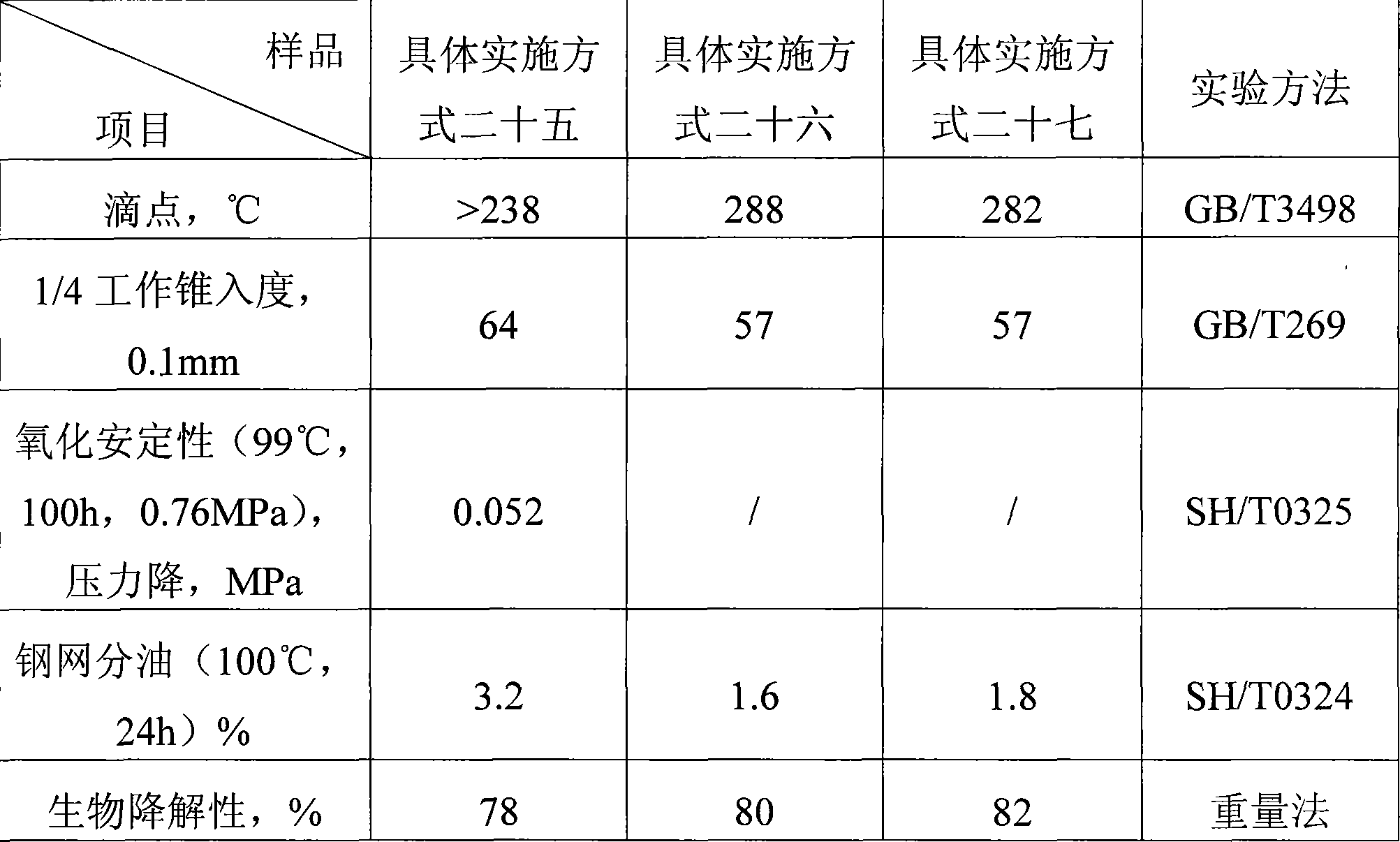

Image

Examples

specific Embodiment approach 1

[0011] Embodiment 1: In this embodiment, an environmentally friendly lubricating grease consists of a base oil accounting for 15-95% of the weight of the grease and a thickener accounting for 5-85% of the weight of the grease.

specific Embodiment approach 2

[0012] Specific Embodiment 2: In this embodiment, an environmentally friendly lubricating grease adds additives accounting for 0-5% of the weight of the lubricating grease.

specific Embodiment approach 3

[0013] Specific embodiment three: a kind of environment-friendly lubricating grease in this embodiment is by accounting for the base oil of 15~94% of lubricating grease weight, accounting for the thickening agent of 6~85% of lubricating grease weight and accounting for 0.05~5% of lubricating grease weight additive composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com