Composite aluminum soap grease and preparation method thereof

A technology for base grease and lubricating grease, applied in the field of composite aluminum base grease and its preparation, can solve the problems of single technology and high cost, and achieve the effect of overcoming low reactivity, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

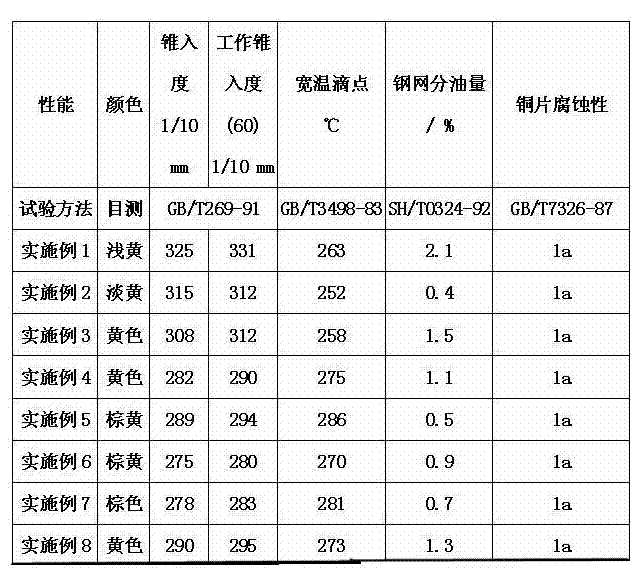

Examples

Embodiment 1

[0020] Example 1: Add 100g of 150BS base oil into an atmospheric pressure esterification kettle, stir and heat up to 60°C, add 0.5g of benzoic acid, 12g of stearic acid, and 7g of 12-hydroxystearic acid, and stir at constant temperature until completely dissolved. Raise the temperature to 100°C, add 1.5g of sodium metaaluminate, saponify at 105°C for 2 hours at low temperature, then slowly raise the temperature to 170°C for 2 hours at medium temperature. Then, continue to heat up to 200 ° C high temperature refining for 1 hour. Finally, add 79g of 150BS base oil, stir, cool, grind, and degas to obtain the composite aluminum-based grease.

Embodiment 2

[0021] Example 2: Add 100g of PAO-20 (polyalphaolefin) base oil into an atmospheric pressure esterification kettle, stir and raise the temperature to 60°C, add 3g of benzoic acid and 16g of stearic acid respectively, and stir at constant temperature until completely dissolved. Raise the temperature to 100°C, add 2g of sodium metaaluminate, saponify at 105°C for 2 hours at low temperature, then slowly raise the temperature to 170°C for 2 hours at medium temperature. Then, continue to heat up to 200 ° C high temperature refining for 1 hour. Finally, 79 g of PAO-20 base oil was added, stirred, cooled, ground and degassed to obtain a composite aluminum-based grease.

Embodiment 3

[0022] Example 3: Add 100g of 150BS base oil into an atmospheric pressure esterification kettle, stir and raise the temperature to 60°C, add 6g of benzoic acid and 12g of stearic acid respectively, and stir at constant temperature until completely dissolved. Raise the temperature to 110°C, add 3 g of sodium metaaluminate, saponify at 120°C for 2 hours at low temperature, then slowly raise the temperature to 160°C for 2 hours at medium temperature. Then, continue to heat up to 210 ° C high temperature refining for 1 hour. Finally, add 79g of 150BS base oil, stir, cool, grind, and degas to obtain the composite aluminum-based grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com