Preparation of lithium ionic secondary cell

A secondary battery and lithium-ion technology, which is applied in secondary battery, electrolyte battery manufacturing, battery electrodes, etc., can solve the problems of poor comprehensive performance and achieve the effect of improving high-temperature storage performance and reducing the loss of irreversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

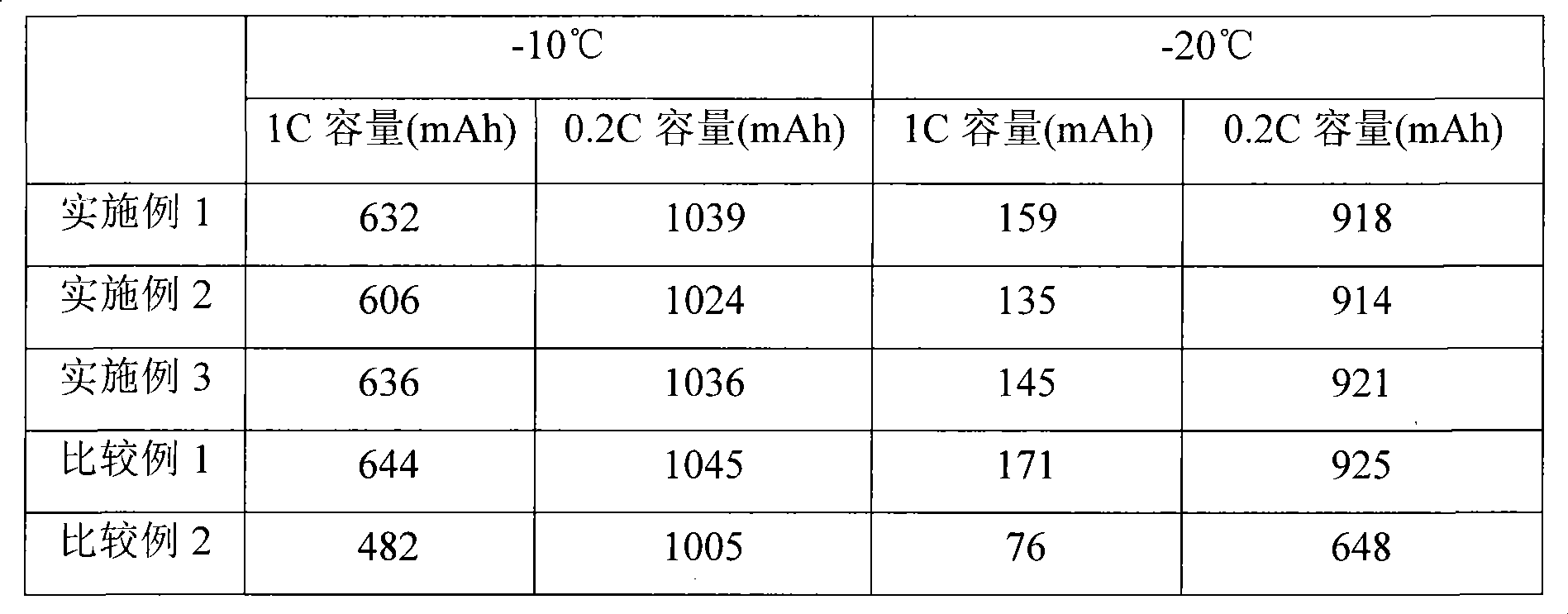

[0011] The preparation method of the lithium-ion secondary battery provided by the present invention includes putting the battery pack into the battery casing, and then injecting the electrolyte solution, wherein, the method of injecting the electrolyte solution includes two injections, and the two injections The liquid method includes injecting a part of the electrolyte into the battery casing for a liquid injection, and then temporarily sealing the battery casing for formation; then adding additives to the remaining part of the electrolyte, and then adding the remaining part of the electrolyte and additives inject together into the formed battery case for secondary liquid injection, and the additive is lithium bisoxalate borate.

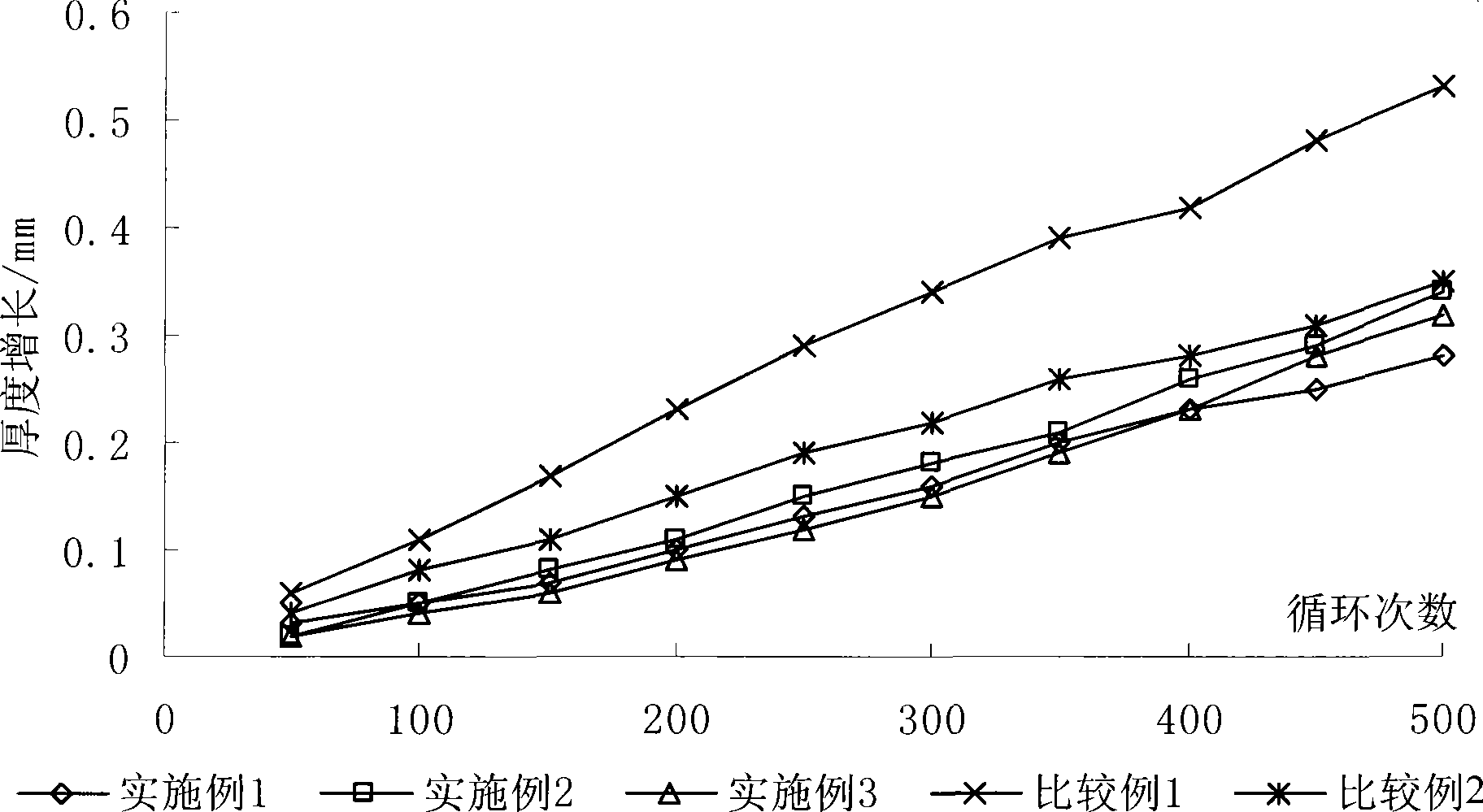

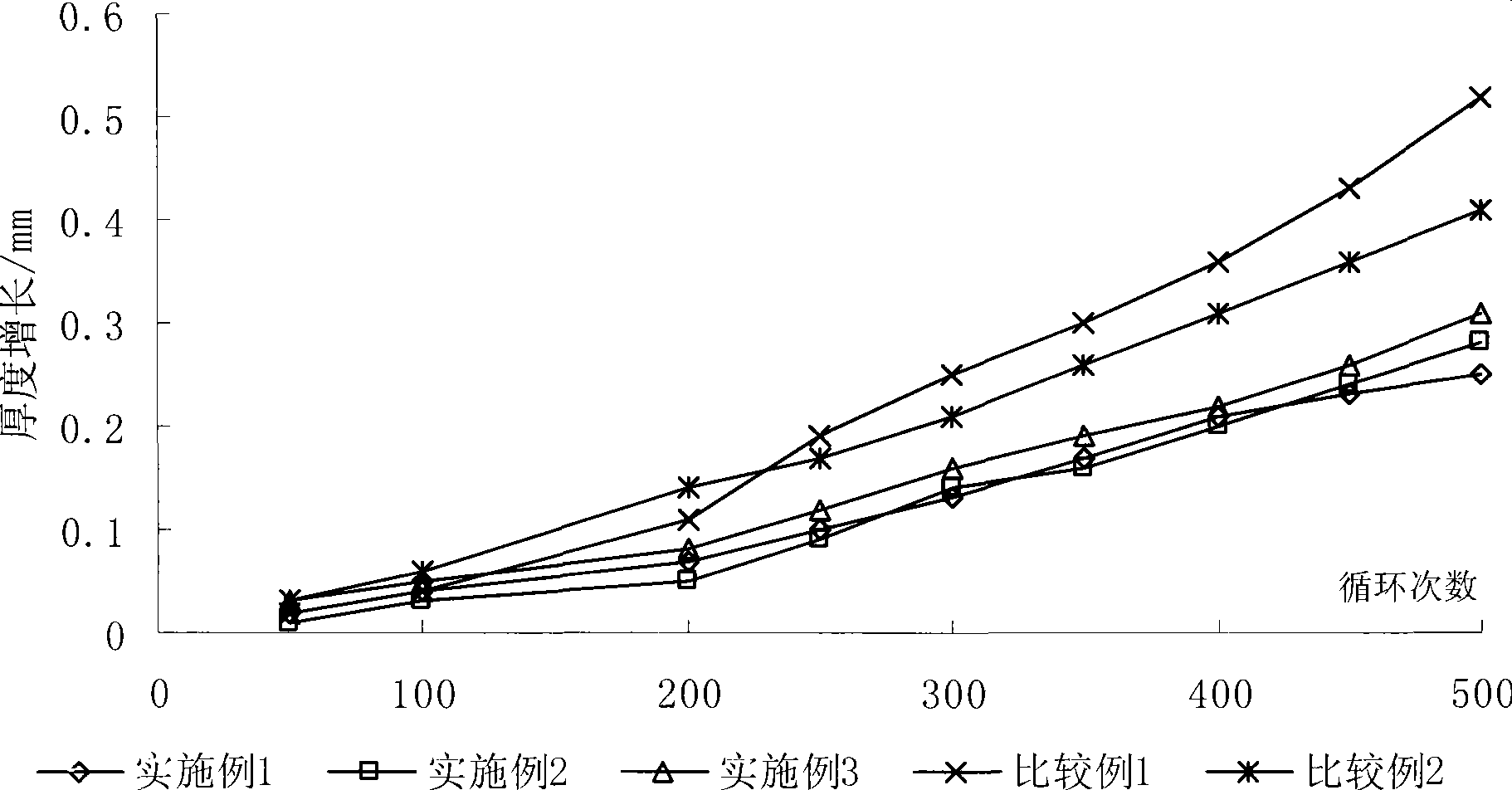

[0012] According to the method provided by the present invention, in the process of injecting the electrolyte into the battery casing, in order to prevent the additive bisoxalate lithium borate (LiBOB) from making the SEI film thicker during the for...

Embodiment 1

[0020] 1. Preparation of positive electrode

[0021] 60 grams of polyvinylidene fluoride (PVDF) was dissolved in 2000 grams of N-methylpyrrolidone (NMP) solvent to prepare a binder solution, and then 1900 grams of lithium cobaltate (LiCoO 2 ) and 40 grams of acetylene black powder were added to the above solution, fully stirred and mixed to obtain a positive electrode slurry; the positive electrode slurry was evenly coated on both sides of the aluminum foil with a pulper, and dried under vacuum at 150°C for 1 hour. Rolled and cut into pieces to make a positive electrode of 485 mm × 44 mm × 125 microns, each positive electrode contains 8 grams of LiCoO 2 .

[0022] 2. Preparation of negative electrode

[0023] 950 grams of graphite, 20 grams of carbon fiber and 30 grams of styrene-butadiene rubber (SBR) were mixed. Add 1500 ml of water and stir evenly to make a negative electrode slurry, apply it evenly on both sides of the copper foil with a pulper, heat and dry under vacuu...

Embodiment 2

[0030] Lithium-ion secondary batteries were prepared in the manner described in Example 1, the difference was that the amount of electrolyte injected during the first liquid injection was 1.75 grams, and during the second liquid injection, 0.0035 grams of LiBOB was added to 1.7465 grams of electrolyte Mix well, and then pour into the battery case.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com