Ionic liquid compound electrolyte material

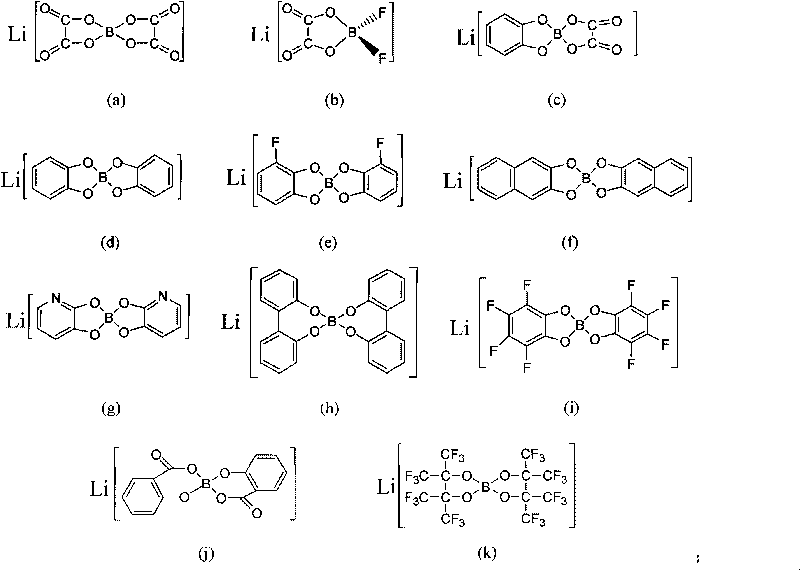

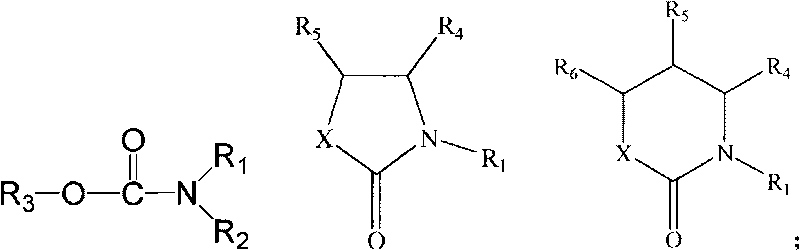

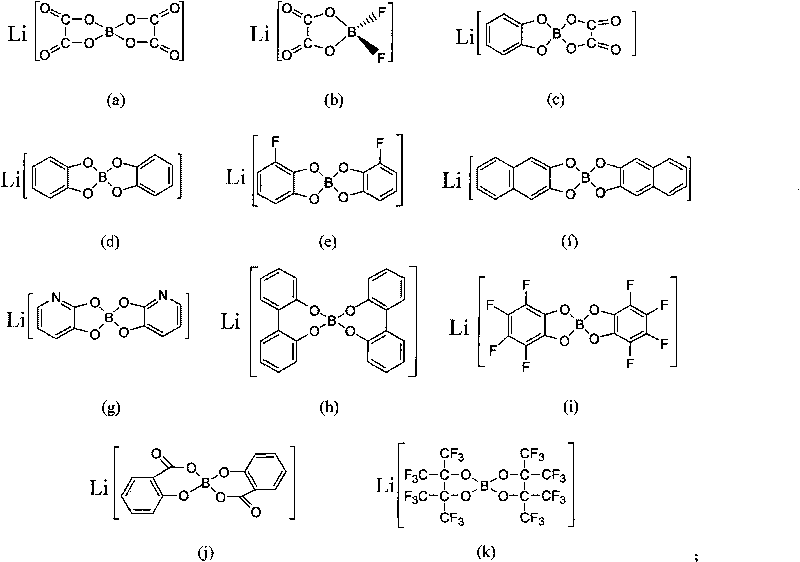

A composite electrolyte and ionic liquid technology, which is used in the manufacture of hybrid capacitor electrolytes, non-aqueous electrolyte batteries, and electrolyte batteries, can solve problems such as gas-liquid leakage, potential safety hazards, and restricting the high-power performance of new batteries and capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dry organic borate lithium (a) and 1,3-nitroxan-2-one and put them in a glove box. Weigh 15g and 45g samples respectively and mix them in a weighing bottle, and stir thoroughly at room temperature A homogeneous liquid is formed and an ionic liquid is obtained. The melting point measured by DSC2010 differential scanning calorimeter is -5℃; the conductivity (25℃) measured by CHI660a electrochemical workstation using AC impedance method is 1.25mS / cm.

[0020] Based on the good electrochemical and thermal properties of the above-mentioned ionic liquid, it is combined with a porous polyoxyethylene membrane, and the conductivity can reach 0.23mS / cm at room temperature at 25°C; the conductivity of the sample at different temperatures is measured, and the conductivity changes with temperature The curve relationship conforms to the Arrhenius equation.

Embodiment 2

[0022] Dry organic borate lithium (b) and 1,3-nitroxan-2-one and put them in a glove box. Weigh 15g and 45g samples respectively and mix them in a weighing bottle, and stir thoroughly at room temperature A homogeneous liquid is formed and an ionic liquid is obtained. The melting point measured by DSC2010 differential scanning calorimeter is -32℃; the conductivity (25℃) measured by CHI660a electrochemical workstation using AC impedance method is 2.4mS / cm.

[0023] Based on the good electrochemical and thermal properties of the above-mentioned ionic liquid, it is compounded with a porous polyoxyethylene membrane, and the conductivity can reach 0.8mS / cm at room temperature at 25℃; the conductivity of the sample at different temperatures is measured, and the conductivity changes with temperature The curve relationship conforms to the Arrhenius equation.

Embodiment 3

[0025] Based on the good electrochemical and thermal properties of the ionic liquid prepared in Example 2, it is compounded with a polyacrylonitrile membrane, and the conductivity can reach 0.65mS / cm at room temperature at 25°C; the conductivity of the sample at different temperatures is measured, and the conductivity varies with The relationship of the temperature curve conforms to the Arrhenius equation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com