Solid electrolyte and lithium battery comprising the solid electrolyte

A solid electrolyte, lithium battery technology, applied in solid electrolyte, electrolyte immobilization/gelation, non-aqueous electrolyte, etc., can solve the problems of deterioration, lack of flexibility, lithium-air battery is not effective, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] Example 1: Using PVDF, DEME, LiTFSI, 5% by weight SiO 2 , and do not use a separator to prepare a solid electrolyte membrane

[0149] Adding PVDF as a polymer and bis(trifluoromethanesulfonyl)imide N,N-diethyl-N as an ionic liquid to N-methylpyrrolidone (NMP) solvent at a weight ratio of 1:1:1 - After methyl-N-(2-methoxyethyl)ammonium (DEME), and LiTFSI as a lithium salt, 5 parts by weight of SiO as inorganic particles based on 100 parts by weight of DEME was added thereto 2 particles (having an average diameter of about 7 nm to about 20 nm) and stirred for about 20 minutes to prepare a mixed solution. The mixed solution was poured into a Teflon pan, dried in a drying room at room temperature for 2 days, and further dried under vacuum at a temperature of about 60° C. overnight to thereby obtain a solid electrolyte membrane. The solid electrolyte membrane is a flexible free-standing membrane and has a thickness of about 90 μm.

Embodiment 2

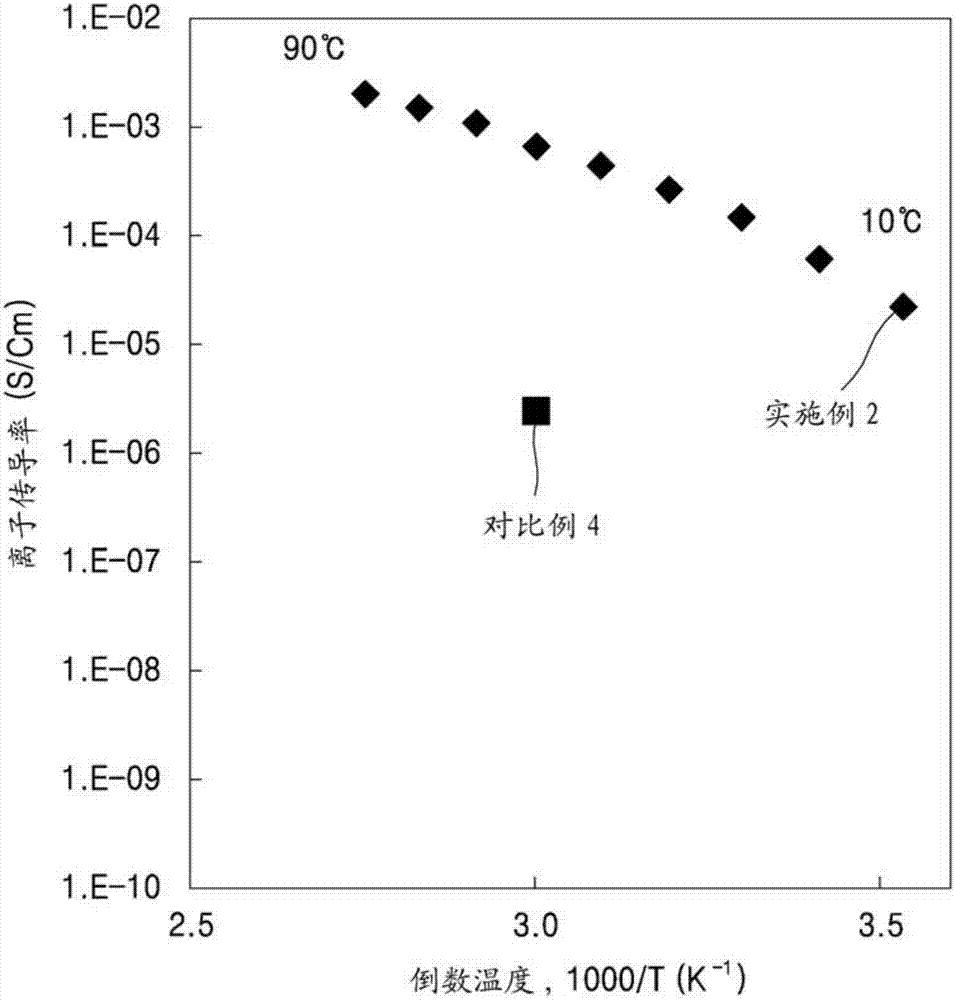

[0150] Example 2: Using PVDF, DEME, LiTFSI, 5% by weight SiO 2 , and a separator to prepare a 90 μm thick solid electrolyte membrane

[0151] After adding PVDF as a polymer, DEME as an ionic liquid, and LiTFSI as a lithium salt to the NMP solvent in a weight ratio of 1:1:1, 5 parts by weight of DEME based on 100 parts by weight of inorganic Granular SiO 2 particles (with an average diameter of about 7nm-20nm) and stirred for about 20 minutes to obtain a mixed solution. The mixed solution permeates the porous separator , dried in a drying room at room temperature for 2 days, and further dried under vacuum at about 60° C. overnight to remove the solvent and thereby obtain a solid electrolyte membrane. The solid electrolyte membrane is a flexible free-standing membrane and has a thickness of about 90 μm.

Embodiment 3

[0152] Example 3: Using PVDF, DEME, LiTFSI, 5% by weight SiO 2 , and a separator to prepare a 60 μm thick solid electrolyte membrane

[0153] A solid electrolyte membrane was prepared in the same manner as in Example 2, except that the thickness of the solid electrolyte membrane was changed to about 60 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com