Composite positive electrode of lithium ion battery as well as preparation method and application to all-solid-state battery thereof

A lithium-ion battery, composite cathode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of limiting the area specific capacity of the composite cathode, the energy density of the all-solid-state battery, the instability of the interface between the chalcogenide electrolyte and some cathode materials, and the limitations The electrochemical performance of composite cathodes can achieve good area specific capacity and energy density, shorten migration distance, and improve energy density and cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

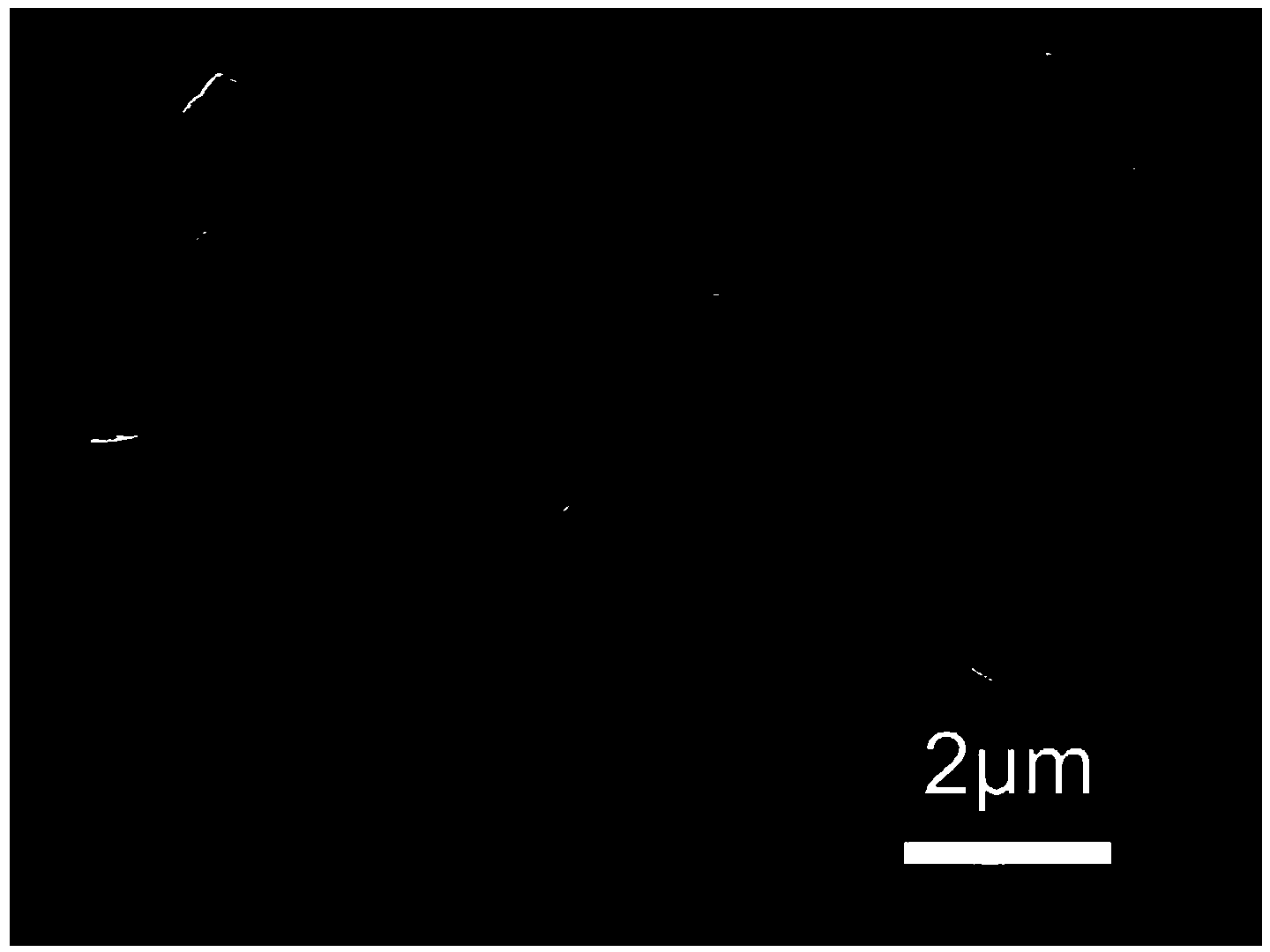

[0051] Embodiment 1, preparation lithium-ion battery composite cathode

[0052] (1) The nickel-cobalt-manganese ternary material (LiNi 0.5 co 0.2 mn 0.3 o 2 ) positive electrode active material, lithium metaborate and lithium fluoride mixed solid electrolyte (mass ratio 3:1), indium tin oxide conductive additive mixed, then mixed by ball milling for 12 hours, dried at 70°C for 10 hours, and dried The mixed powder is pressed into ceramic sheets;

[0053] (2) The ceramic sheet was sintered at 1000° C. for 2 hours to obtain a composite positive electrode, and the thickness was ground to 150 μm with sandpaper.

[0054] In the lithium-ion battery composite positive electrode prepared in this example, the mass fraction of nickel-cobalt-manganese ternary material is 80%, the mass fraction of lithium metaborate and lithium fluoride mixed solid electrolyte is 10%, and the mass fraction of indium tin oxide conductive additive 10%.

Embodiment 2

[0055] Embodiment 2, preparation lithium ion battery composite cathode

[0056] (1) After mixing lithium cobaltate positive electrode active material, lithium borate solid electrolyte and tin dioxide conductive additive, ball milling and mixing for 24 hours, drying at 100°C for 6 hours, and pressing the dried mixed powder into ceramics piece;

[0057] (2) The ceramic sheet was sintered at 700° C. for 10 hours to obtain a composite positive electrode, which was ground into a sheet with a thickness of 1000 μm by sandpaper.

[0058] In the lithium ion battery composite positive electrode prepared in this embodiment, the mass fraction of lithium cobaltate is 90%, the mass fraction of lithium borate solid electrolyte is 5%, and the mass fraction of tin dioxide conductive additive is 5%.

Embodiment 3

[0059] Embodiment 3, preparation lithium ion battery composite cathode

[0060] (1) After mixing lithium manganate positive electrode active material, lithium borate, lithium metaborate and lithium fluoride mixed solid electrolyte (mass ratio 1:1:1), nickel oxide conductive additive, and then ball milling and mixing for 36 hours, at 150 Dry at ℃ for 2 hours, and press the dried mixed powder into ceramic sheets;

[0061] (2) The ceramic sheet was sintered at 800° C. for 4 hours to obtain a composite positive electrode, and the thickness was ground to 500 μm with sandpaper.

[0062] In the lithium ion battery composite cathode prepared in this embodiment, the mass fraction of lithium manganate is 40%, the mass fraction of lithium borate, lithium metaborate and lithium fluoride mixed solid electrolyte is 40%, and the mass fraction of nickel oxide conductive additive is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com