Electrolyte system for preventing spinel lithium titanate radical lithium ion secondary battery from flatulence

A lithium titanate, secondary battery technology, applied in the field of batteries, can solve the problems of difficult formation of SEI film, affecting battery life, etc., and achieve the effects of improving cycle life, preventing flatulence, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

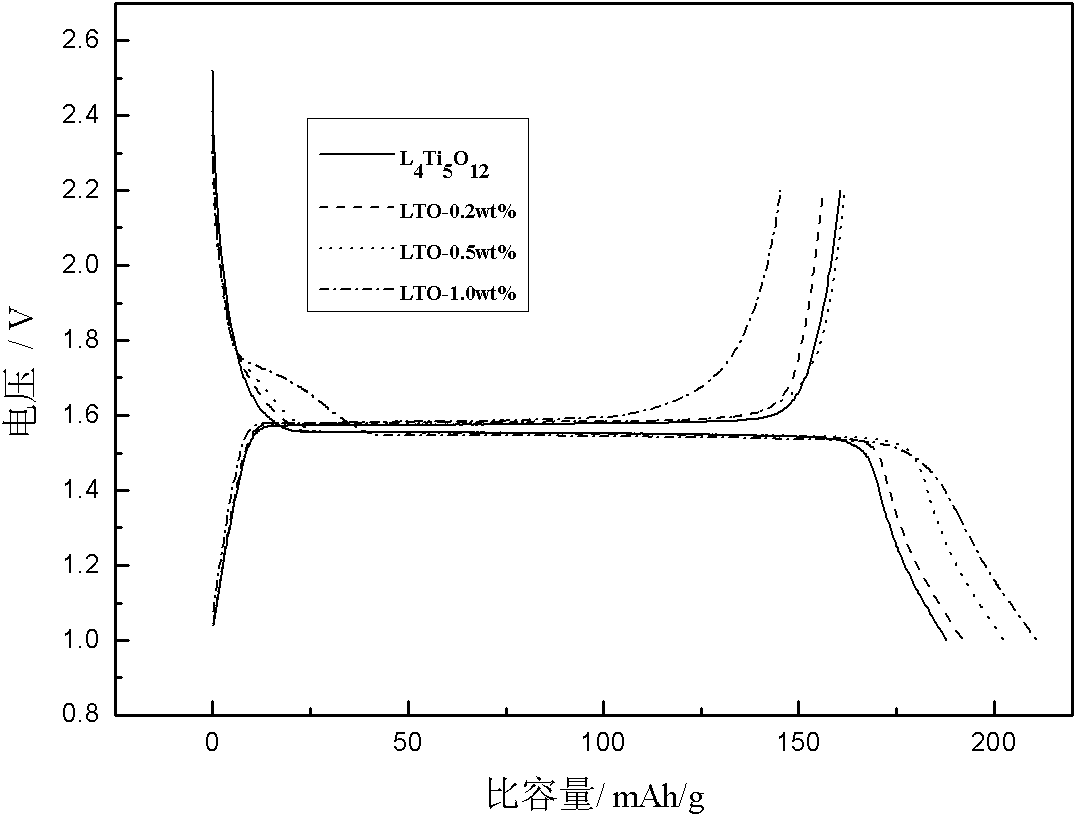

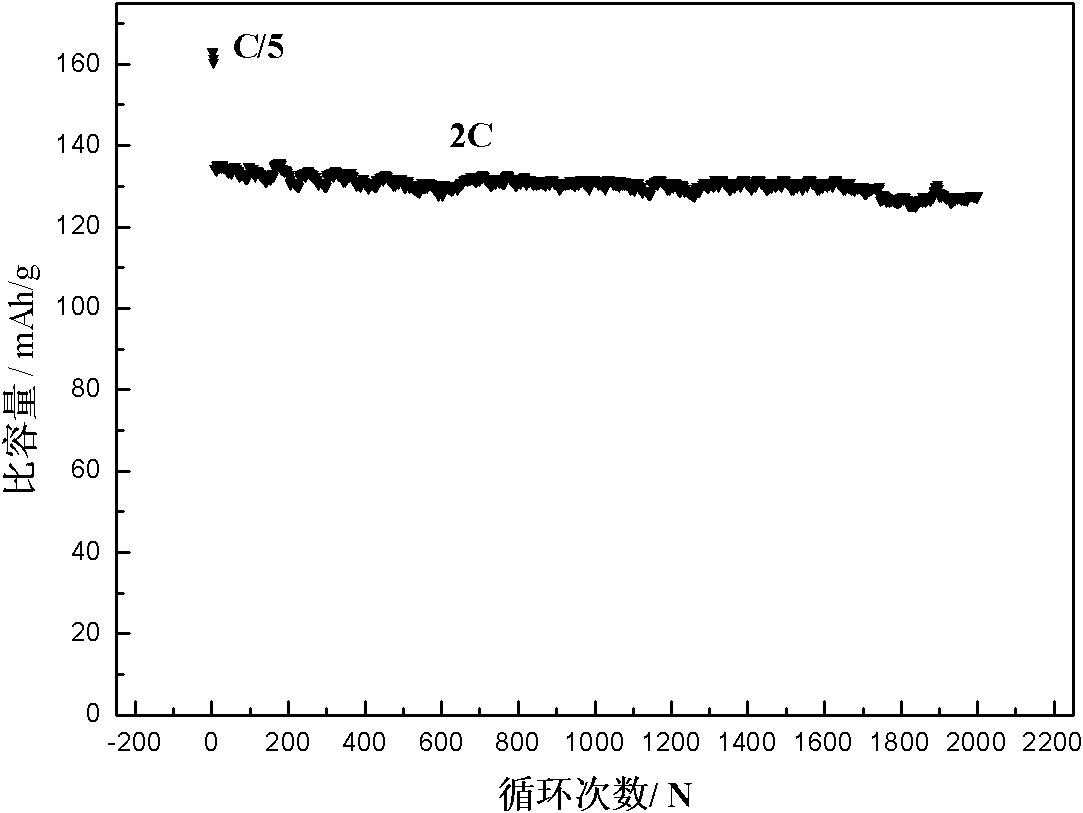

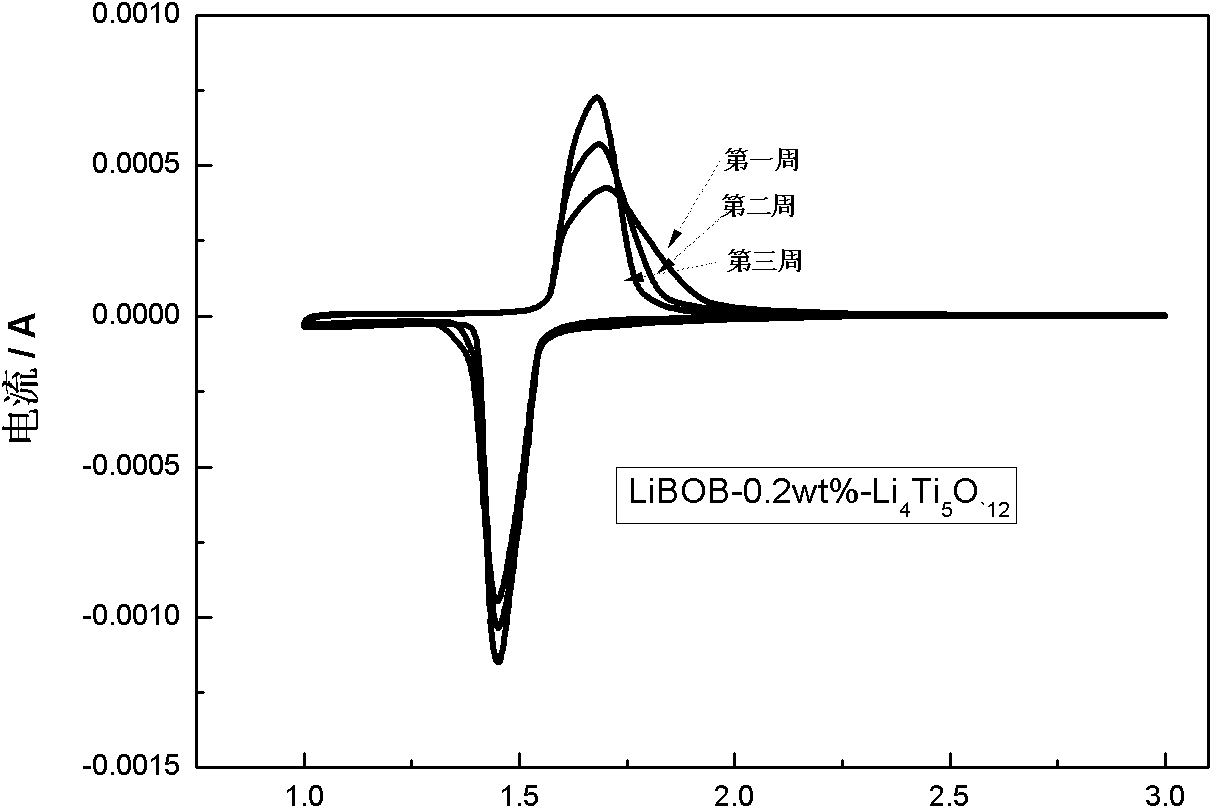

Embodiment 1

[0021] Li / Li 4 Ti 5 o 12 The system simulates the battery, the specific process is as follows:

[0022] Weigh Li respectively according to weight percentage 8:1:1 4 Ti 5 o 12 , acetylene black and polyvinylidene fluoride (PVDF), using pyrrolidone as a dispersant, stir and mix them evenly. Using aluminum foil as a current collector, the mixed slurry was rolled into a pole piece with a thickness of 50 μm by a rolling machine. The electrolyte uses organic electrolytes EC (ethylene carbonate) and DEC (diethyl carbonate), EC:DEC=1:1, and the electrolyte is 1mol / L LiBF 4 5 wt% lithium bisoxalate borate (LiBOB) is added into the system as a film-forming additive, and the water content of the obtained electrolytic solution is lower than 10 ppm.

Embodiment 2-6

[0024] Weigh a certain amount of Li according to the weight percentage 8:1:1 4 Ti 5 o 12 , acetylene black and polyvinylidene fluoride (PVDF), using pyrrolidone as a dispersant, stir and mix them evenly. Using aluminum foil as a current collector, the mixed slurry was rolled into a pole piece with a thickness of 50 μm by a rolling machine.

[0025] As described in Example 1, the film-forming additives are respectively 0.001wt%, 1wt%, 3wt% and 10wt%, 30wt%, the organic electrolyte solvent is PC (propylene carbonate), and the electrolyte is 1mol / L LiPF 6 , The water content of the obtained electrolyte is lower than 10ppm.

Embodiment 7-42

[0027] Li / Li 4 Ti 5 o 12 The system simulates the battery, the specific process is as follows:

[0028] Weigh a certain amount of Li according to the weight percentage 8:1:1 4 Ti 5 o 12 , acetylene black and polyvinylidene fluoride (PVDF), using pyrrolidone as a dispersant, stir and mix them evenly. Using aluminum foil as a current collector, the mixed slurry was rolled into a pole piece with a thickness of 50 μm by a rolling machine.

[0029] As described in Example 1, the film-forming additives are sequentially used bis(2,3-naphthalenediol)lithium borate (LBNB), bis(2,2'-biphenyldioxy)lithium borate (LBBPB), di Lithium (salicylic acid) borate (LBSB), lithium bis(2,3-pyridyldioxy)borate (LBPB), malonate oxalate borate (LiMOB), lithium bis(catechol)borate (LBBB) ) instead, the additions are respectively: 0.001wt%, 1wt%, 3wt% and 10wt%, 30wt%, the electrolyte adopts organic electrolyte EC and DMC (dimethyl carbonate), EC: DMC=1: 1, electrolyte 1mol / L LiBF 4 , The water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com