Composite lithium ion battery electrolyte and lithium ion battery comprising same

A technology of lithium-ion batteries and electrolytes, applied in electrolytes, secondary batteries, organic electrolytes, etc., can solve the problems of reduced initial charge and discharge capacity, improve cycle performance, improve high-temperature storage and cycle performance, and increase high-voltage capacity and the effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

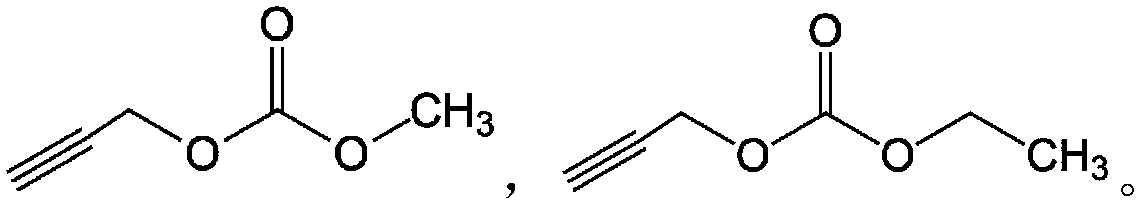

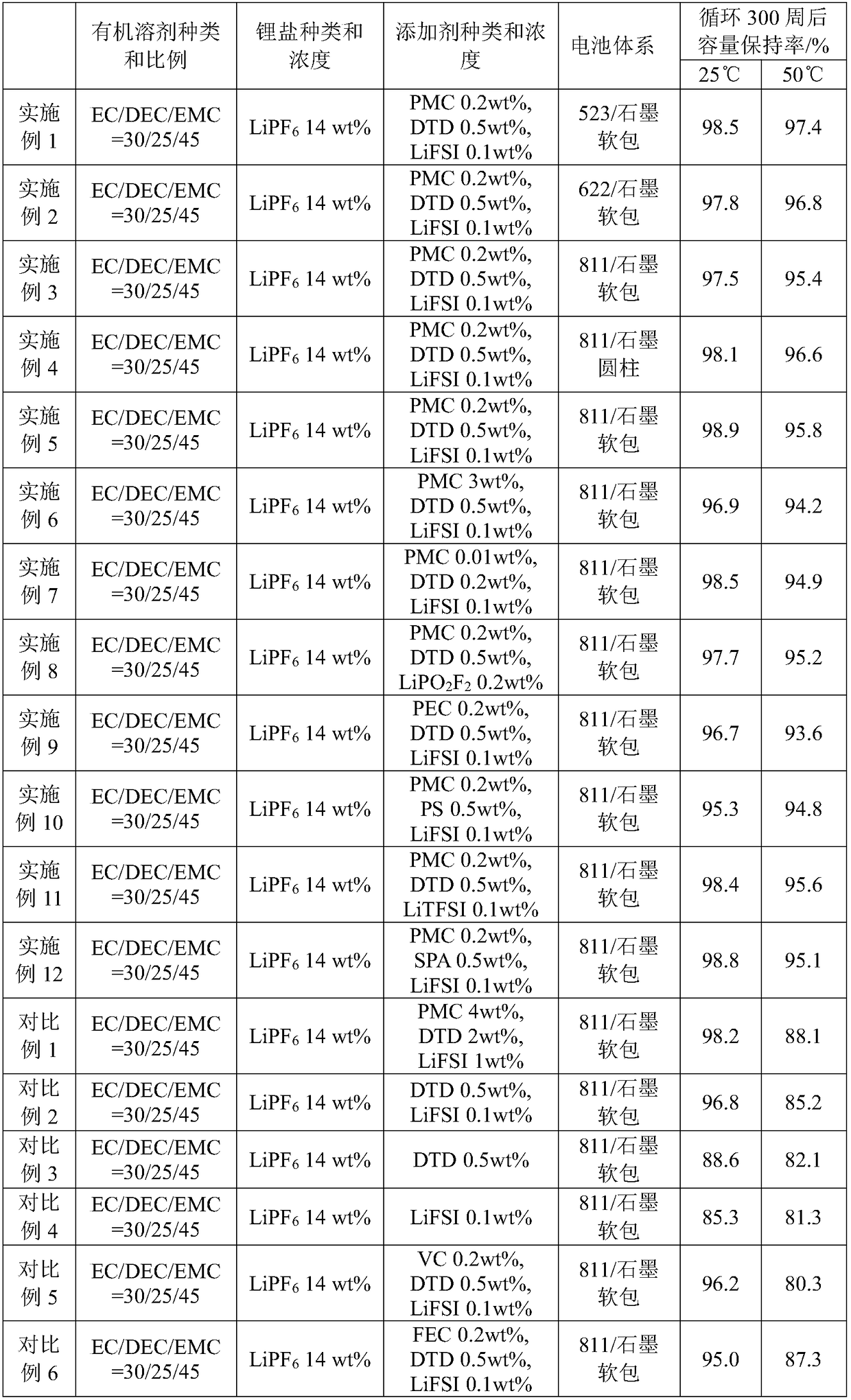

[0034] A composite lithium ion battery electrolyte is composed of organic solvent, lithium salt, 2-propargyl methyl carbonate, DTD and LiFSI. In an argon glove box with a moisture content of less than 10 ppm, EC, DEC, and EMC were mixed uniformly in a mass ratio of 30:25:45, and then slowly added LiPF accounting for 14wt% of the total electrolyte 6 Lithium salt, finally, adding 2-propargyl methyl carbonate accounting for 0.2 wt% of the total electrolyte, DTD accounting for 0.5 wt% of the total electrolyte, and LiFSI accounting for 0.1 wt% of the total electrolyte. Using the electrolyte of this example for LiNi 0.5 Co 0.2 Mn 0.3 O 2 / Graphite pouch battery (NCM523).

Embodiment 2

[0036] A composite lithium ion battery electrolyte is composed of organic solvent, lithium salt, 2-propargyl methyl carbonate, DTD and LiFSI. In an argon glove box with a moisture content of less than 10 ppm, EC, DEC, and EMC were mixed uniformly in a mass ratio of 30:25:45, and then slowly added LiPF accounting for 14wt% of the total electrolyte 6 Lithium salt, finally, adding 2-propargyl methyl carbonate accounting for 0.2 wt% of the total electrolyte, DTD accounting for 0.5 wt% of the total electrolyte, and LiFSI accounting for 0.1 wt% of the total electrolyte. Using the electrolyte of this example for LiNi 0.6 Co 0.2 Mn 0.2 O 2 / Graphite pouch battery (NCM622).

Embodiment 3

[0038] The preparation process of the electrolyte in this embodiment is the same as that in Example 1. The electrolyte is composed of an organic solvent, lithium salt, 2-propargyl methyl carbonate, DTD, and LiFSI. The organic solvent is composed of EC, DEC, and EMC, and the mass ratio of EC, DEC, and EMC is 30:25:45, and the lithium salt is LiPF 6 , accounted for 14wt% of the total electrolyte, additive 2-propargyl methyl carbonate accounted for 0.2wt% of the total electrolyte, DTD accounted for 0.5wt% of the total electrolyte, LiFSI accounted for 0.1wt% of the total electrolyte %. Using the electrolyte of this example for LiNi 0.8 Co 0.1 Mn 0.1 O 2 / Graphite pouch battery (NCM811).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com