Tungstic oxide nano-wire and method for preparing tungstic oxide nano-wire gas-sensitive sensor

A technology of tungsten oxide nanowires and gas sensor, which is applied in the field of wide-range hydrothermal preparation of hexagonal tungsten oxide nanowires and gas sensing applications, can solve the problems of expensive raw materials, difficult sensitive films, and long film forming cycles, and achieve The preparation method and preparation steps are simple, the process parameters are easy to control, and the preparation method has a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

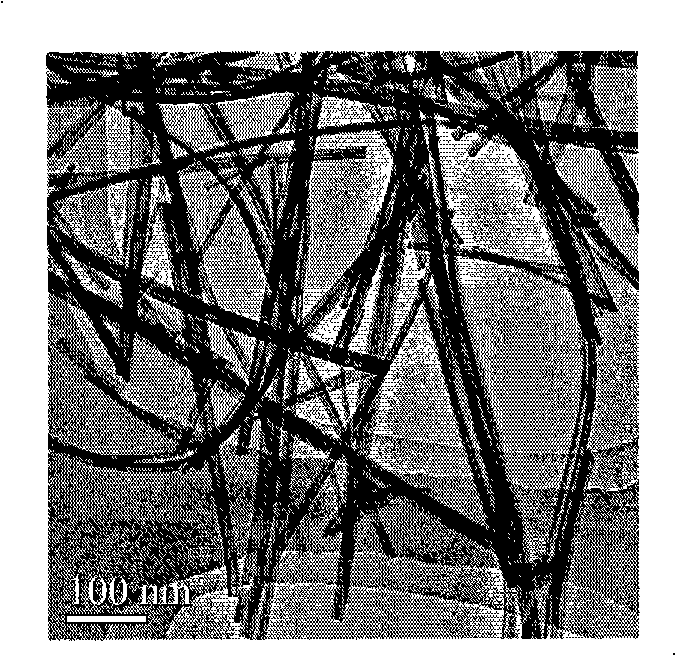

Image

Examples

preparation example Construction

[0032] The preparation process of the tungsten oxide nanowire gas sensor is the same as that described in the summary of the invention. Nine specific implementation examples of preparing tungsten oxide nanowire gas sensor in the present invention are shown in Table 2.

[0033] Table 2 prepares the specific embodiment of tungsten oxide nanowire gas sensor

[0034]

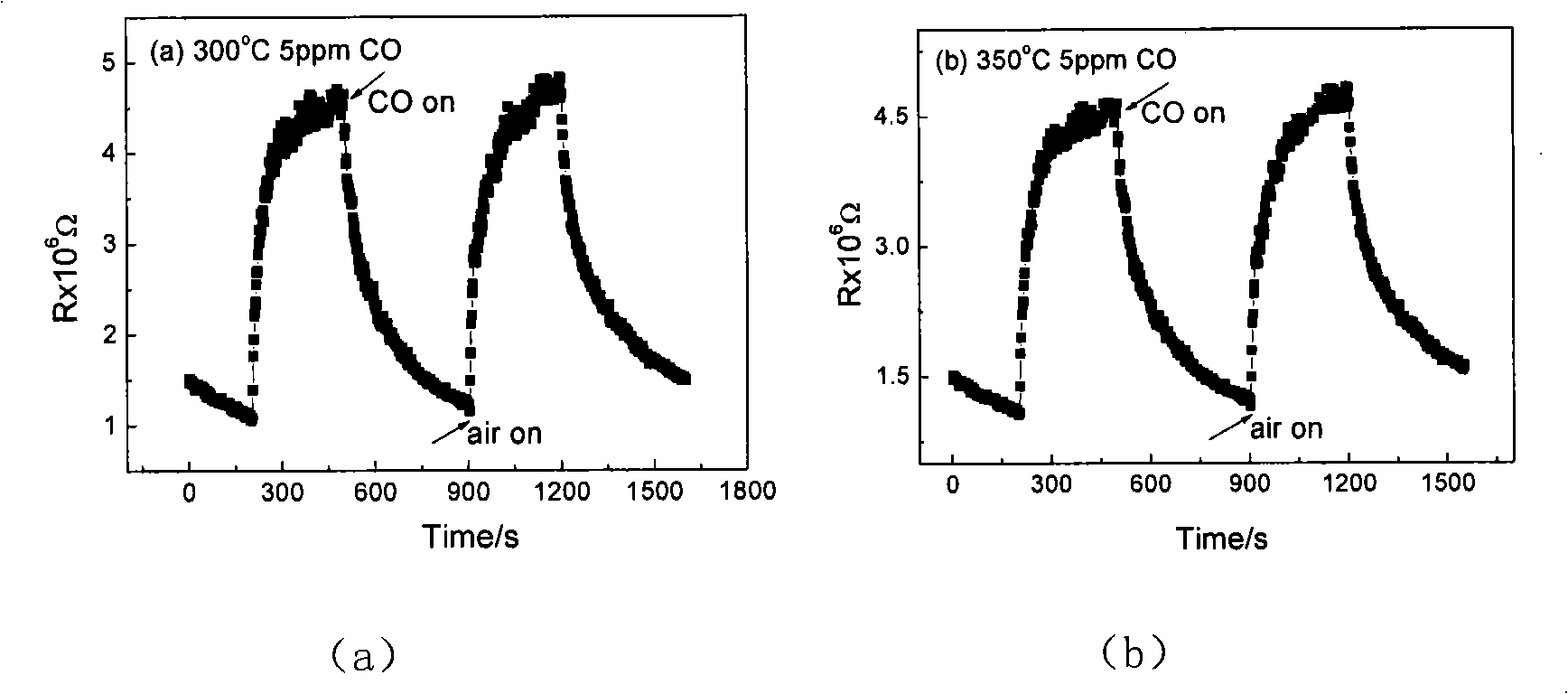

[0035] 3. Gas sensing characteristics of tungsten oxide nanowire gas sensor

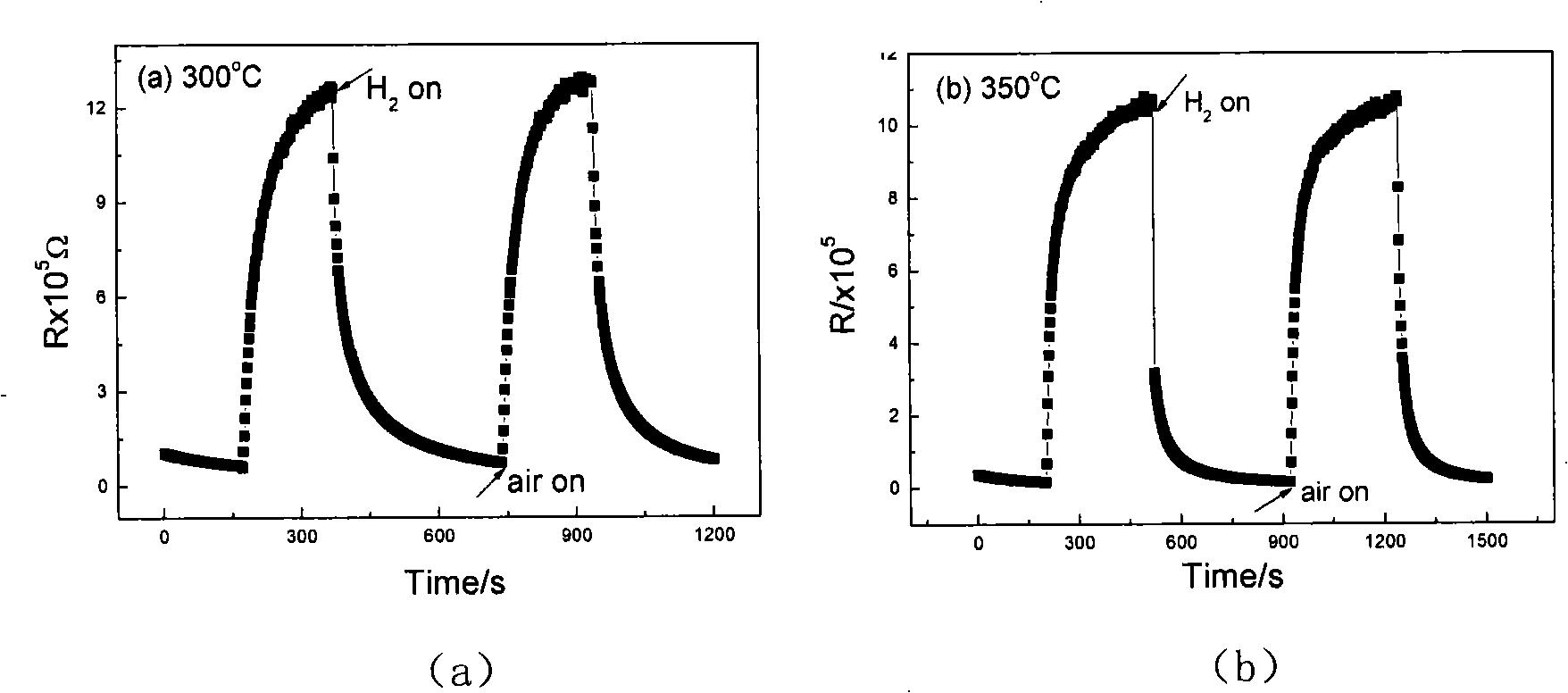

[0036] 1. Tungsten oxide nanowire gas sensor for H 2 gas sensitive properties

[0037] With the tungsten oxide nanowires prepared in the third embodiment in Table 1 as the gas-sensing material, the tungsten oxide nanowire gas sensor was prepared in the second embodiment of the tungsten oxide nanowire gas sensor in Table 2. The gas sensitivity characteristics to 1ppmH2 at ℃ and 350℃ are as follows: figure 2 (a) and (b) shown. from figure 2 It can be seen from (a) and (b) that during the test of 1ppm H2, the resistance value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com