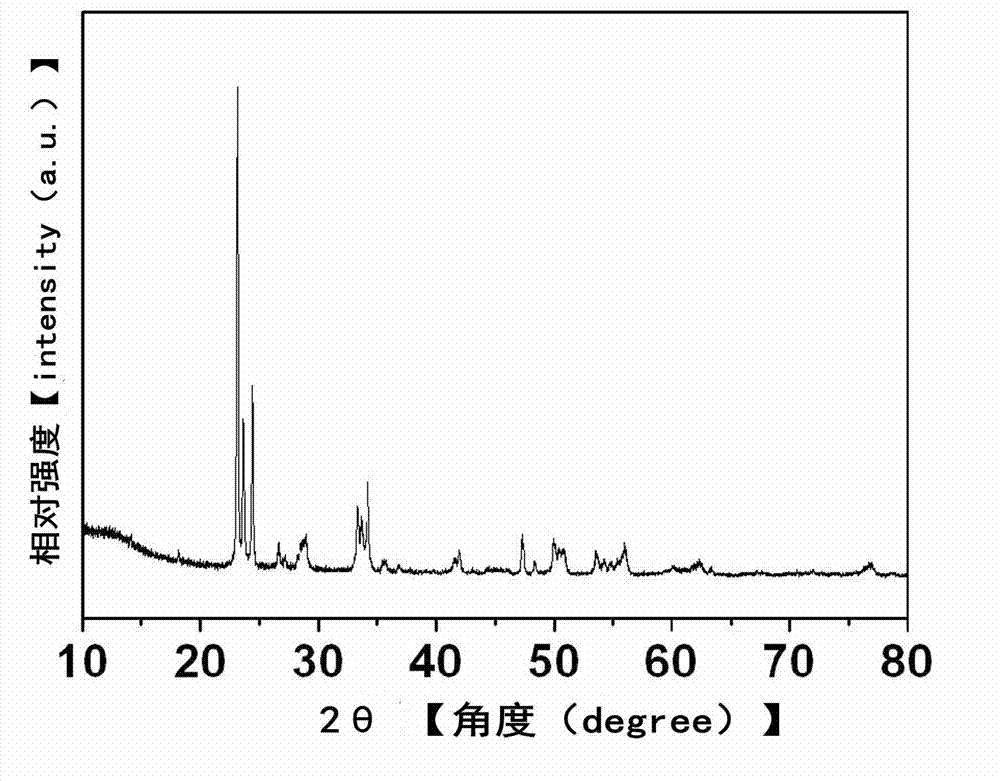

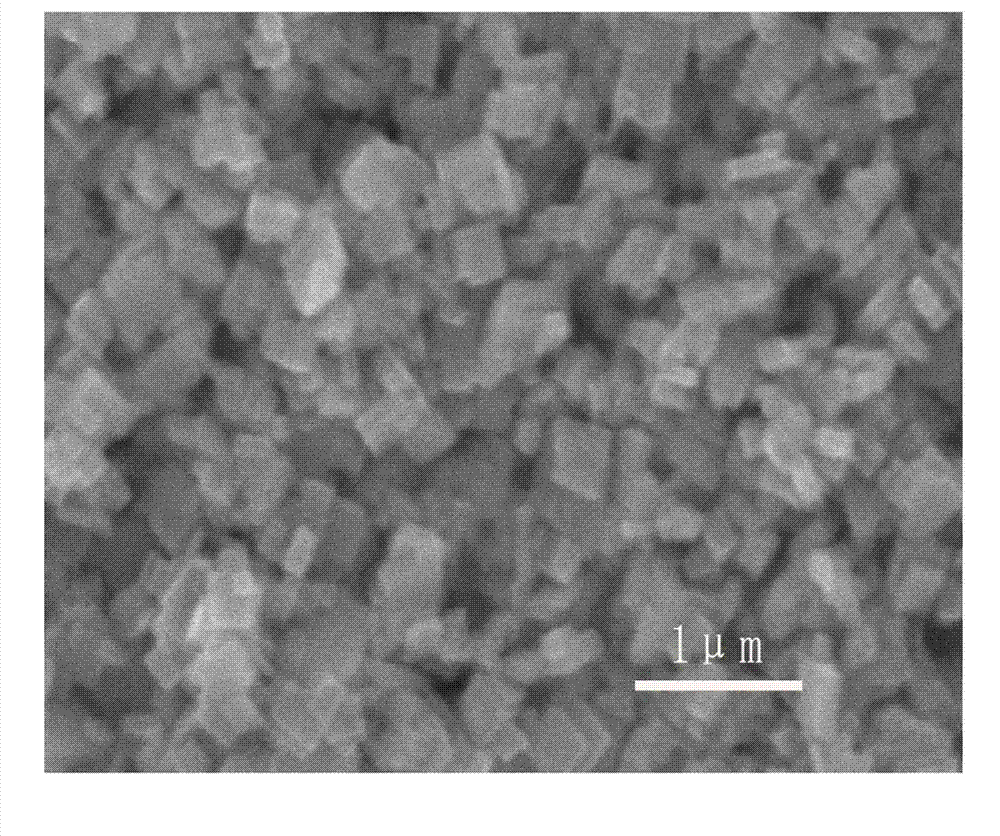

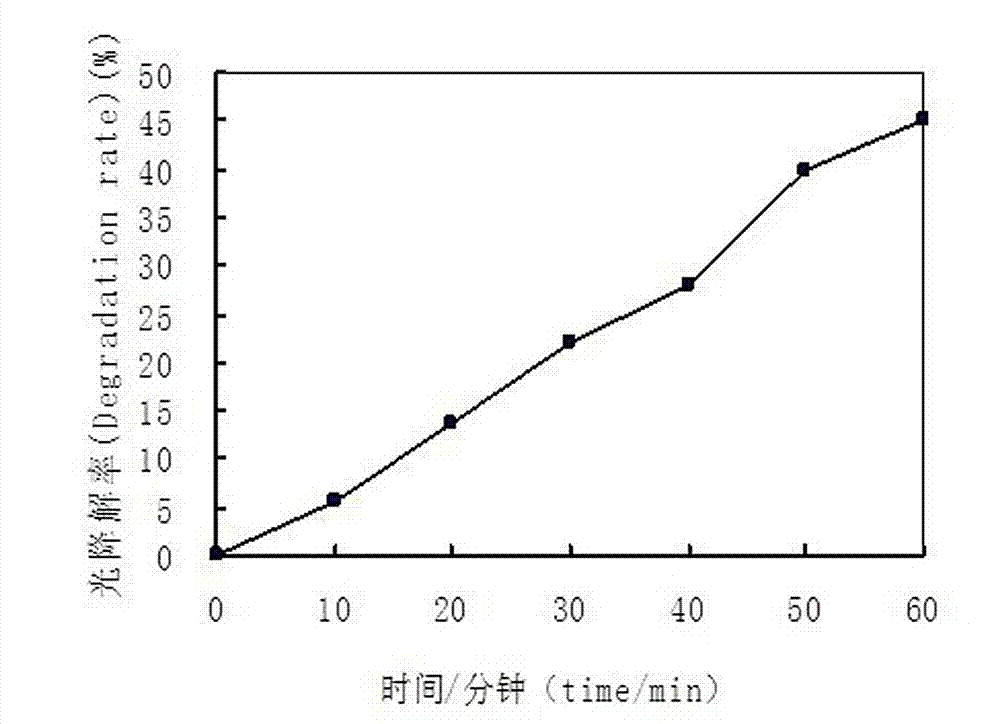

Tungsten trioxide nano-sheet prepared by hydrothermal method and application of tungsten trioxide nano-sheet

A technology of tungsten trioxide and nanosheets, applied in tungsten oxide/tungsten hydroxide, nanotechnology, nanotechnology, etc., to achieve good reproducibility, convenient mass production, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of tungsten trioxide (WO 3 ) The preparation method of nanosheets is carried out according to the following steps:

[0030] A. Dilute concentrated nitric acid with a concentration of 65% into 30 mL of dilute nitric acid with a concentration of 10%;

[0031] B. Weigh 0.5 g Na 2 WO 4 2H 2 O, add 5 mL of deionized water and stir to mix well to form Na 2 WO 4 2H 2 O transparent solution;

[0032] C, the Na 2 WO 4 2H 2 O transparent solution was added in the 30 mL dilute nitric acid solution described in step A, stirred for 30 min, accompanied by the color of the precipitate turning from white to light yellow;

[0033] D. Transfer the mixed system obtained in step C to a polytetrafluoroethylene-lined reactor, raise the temperature to 140° C. for 18 h, and cool naturally to obtain a hydrothermal product;

[0034] E, centrifuging the hydrothermal product obtained in step D, washing with deionized water and ethanol three times respectively;

[0035] F. Dry th...

Embodiment 2

[0043] A kind of tungsten trioxide (WO 3 ) The preparation method of nanosheets is carried out according to the following steps:

[0044] A. Dilute concentrated nitric acid with a concentration of 65% into 30 mL of dilute nitric acid with a concentration of 10%;

[0045] B. Weigh 0.6 g Na 2 WO 4 2H 2 O, add 10 mL of deionized water, stir to mix evenly, and form Na 2 WO 4 2H 2 O transparent solution;

[0046] C, the Na 2 WO 4 2H 2 O solution was added in the 30 mL dilute nitric acid solution described in step A, stirred for 30 min, and the color of the precipitate changed from white to light yellow;

[0047] D. Transfer the mixed system obtained in step C to a polytetrafluoroethylene-lined reaction kettle, raise the temperature to 200° C. for 30 h, and cool naturally to obtain a hydrothermal product;

[0048] E, centrifuging the hydrothermal product obtained in step D, washing with deionized water and ethanol three times respectively;

[0049] F. Dry the centrifuged...

Embodiment 3

[0051] A kind of tungsten trioxide (WO 3 ) The preparation method of nanosheets is carried out according to the following steps:

[0052] A. Dilute concentrated nitric acid with a concentration of 65% into 30 mL of dilute nitric acid with a concentration of 12%;

[0053] B. Weigh 0.5 g Na 2 WO 4 2H 2 O, add 5 mL of deionized water and stir to mix well to form Na 2 WO 4 2H 2 O transparent solution;

[0054] C, the Na 2 WO 4 2H 2 O solution was added in the 30 mL dilute nitric acid solution described in step A, stirred for 30 min, and the color of the precipitate changed from white to light yellow;

[0055] D. Transfer the mixed system obtained in step C to a polytetrafluoroethylene-lined reactor, raise the temperature to 140° C. for 30 h, and cool naturally to obtain a hydrothermal product;

[0056] E, centrifuging the hydrothermal product obtained in step D, washing with deionized water and ethanol three times respectively;

[0057] F. Dry the centrifuged product i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com