Preparation method of quantum dot self-assembling nano structural material

A nanostructure and self-assembly technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of complex preparation process, high process requirements, difficult mass preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

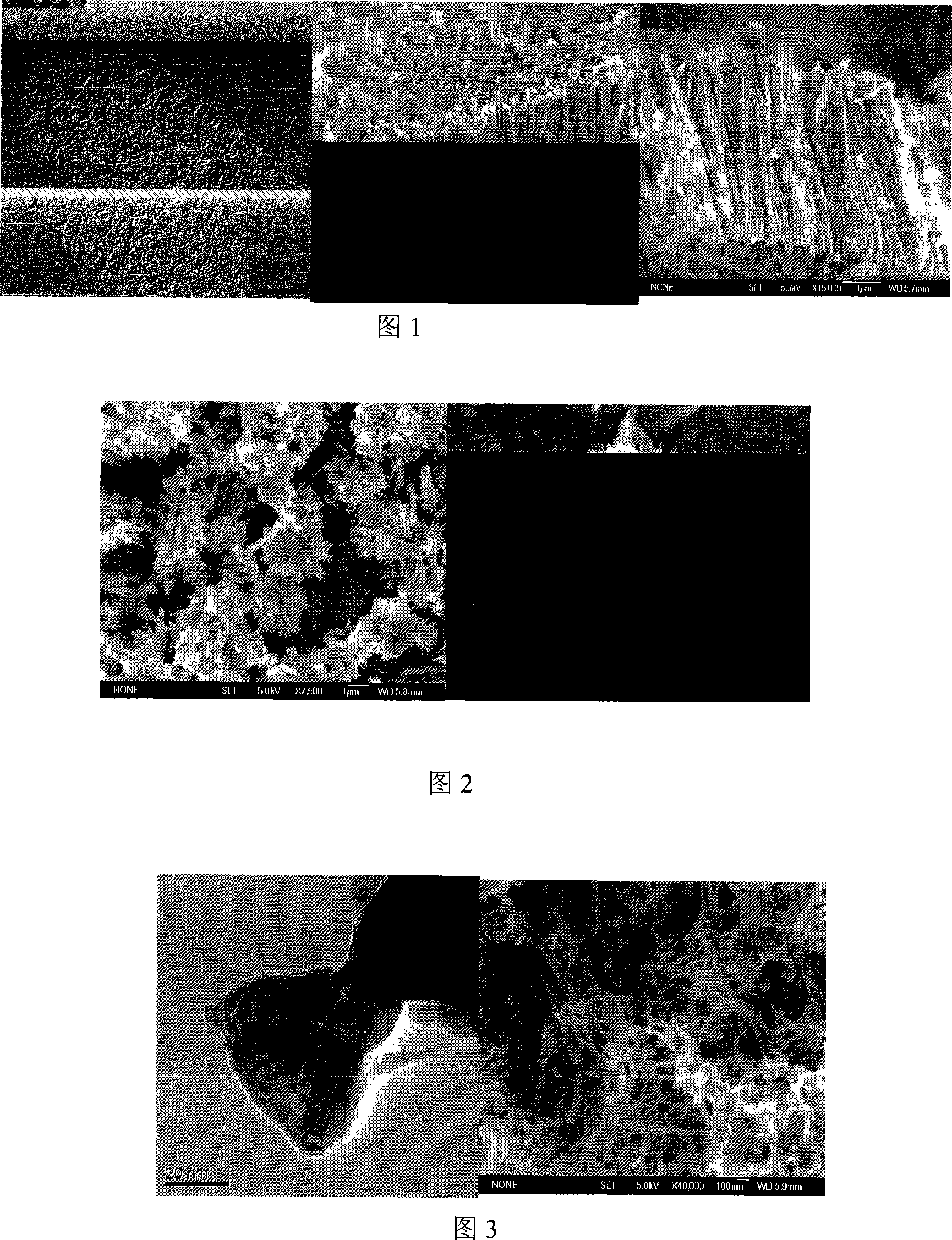

[0038] Example 1: 0.4 g of copper acetate monohydrate was dissolved in 70 ml of diethylene glycol, and the solution was heated to 180° C. with stirring. At the same time, 0.075 g of thioacetamide was dissolved in 30 ml of diethylene glycol by ultrasonic method, and the solution was sealed and allowed to stand for 3 hours, then added to the above-mentioned 180°C copper acetate solution, and reacted for 3 hours to obtain black suspension. After the system was naturally cooled to room temperature, the black product was separated by centrifugation, washed three times with absolute ethanol, and dried in a vacuum oven to obtain the final self-assembled upright nanorod array of cuprous sulfide quantum dots. It can be seen from the transmission and scanning electron microscope photos (Fig. 1) that the upright nanorod array is self-assembled by small particles of about 5 nanometers.

[0039] Keep above-mentioned same preparation condition, just change the time that thioacetamide digly...

Embodiment 2

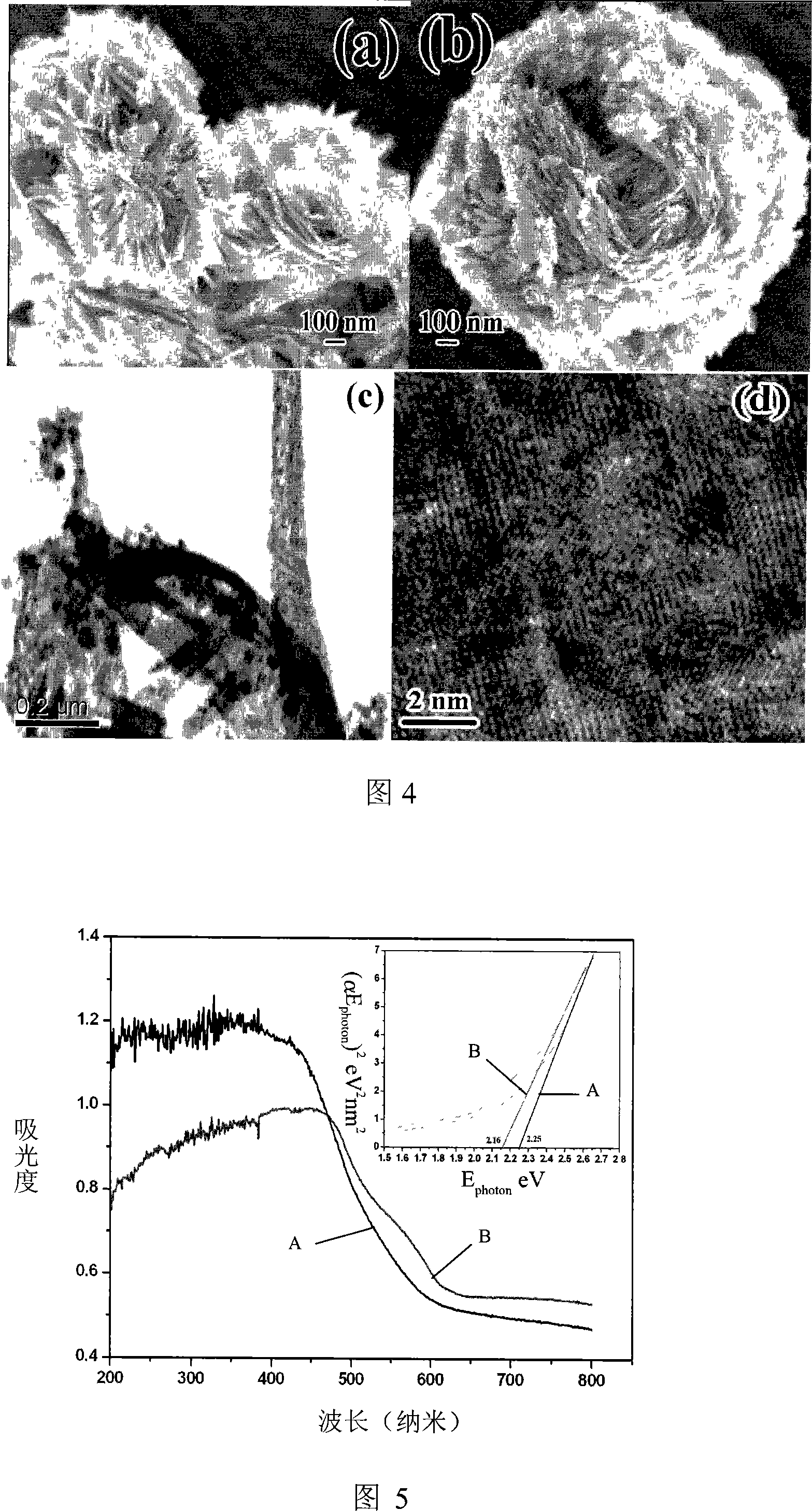

[0043] Example 2: 2.3 mmol / L anhydrous copper acetate and 4.3 mmol / L acetamide were ultrasonically dissolved in 50 ml of diethylene glycol solvent, the solution was heated to 180° C. and kept at this temperature for 8 hours, A yellow precipitate precipitated out. After the suspension solution was cooled to room temperature, the precipitate was separated by centrifugation, and the solvent was washed away with ethanol, and a yellow product was obtained after drying in a vacuum oven for 5 hours. The product is a flower-like super nanostructure formed by self-assembly of 3-5 nanometer quantum dots, and its scanning and transmission electron microscope photos are shown in FIG. 4 . What Fig. 5 shows is the spectrogram of the ultraviolet diffuse reflectance of this structural material and corresponding calculated energy band width (bandgap energy) (curve A in the figure), with our own cuprous oxide 200 nanometer cube (curve B in the figure ), the absorption peak of the flower-like n...

Embodiment 3

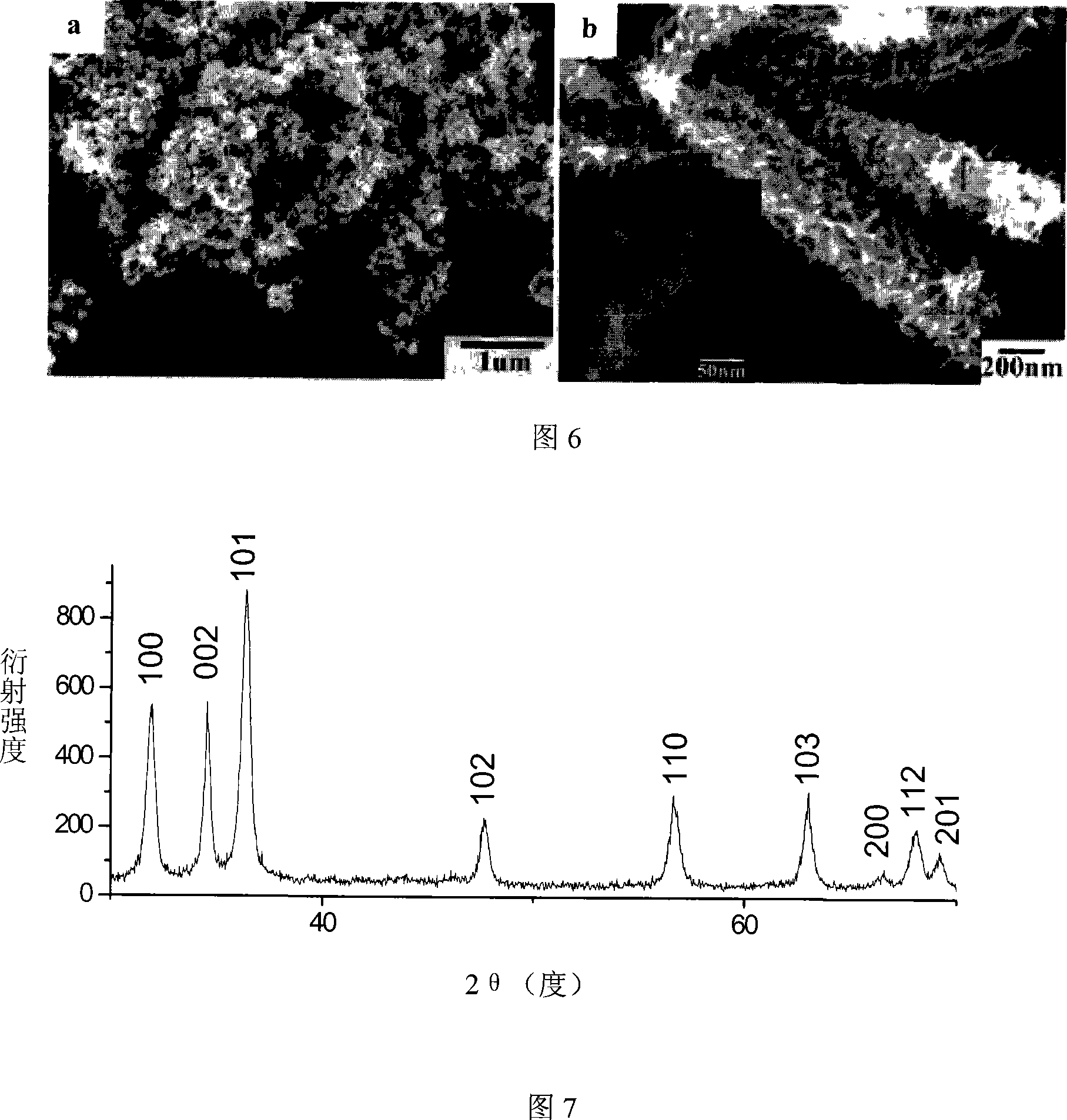

[0044] Example 3: 3 grams of zinc acetate was mixed with 300 milliliters of ethylene glycol solvent, ultrasonically dissolved, and the temperature was raised to 250° C. under vigorous stirring. After the hydrolysis reaction continued for 2 hours, it was cooled to room temperature. After centrifugation, washing, and repeating 3 times, the white ZnO super nanostructure can be obtained by drying in an oven. Observation by high-resolution transmission electron microscopy reveals that the nanostructure is a dendritic structure formed by self-assembly of single crystals of 3-10 nanometers (as shown in FIG. 6 ). XRD detection proves that the crystal is ZnO (see Figure 7).

[0045] The preparation process of the CdO quantum dot self-assembled super nanostructure is basically the same as the above, except that the solvent is butanediol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com