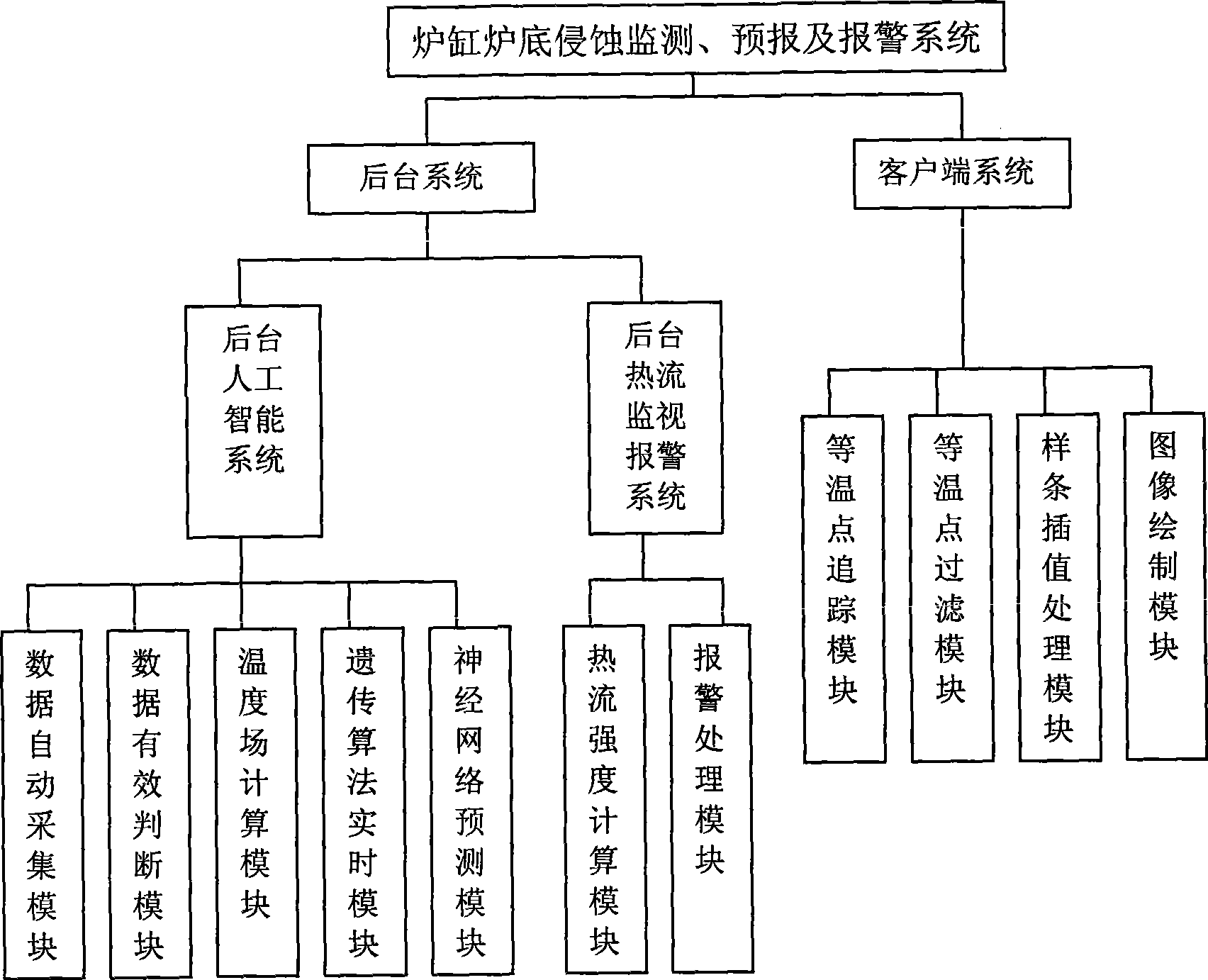

Monitoring, prediction and alarm system for blast furnace hearth and bottom

An alarm system and technology for blast furnaces, applied in the fields of forecasting, alarm systems, and hearth and bottom monitoring of blast furnaces, can solve problems such as large differences, and achieve the effects of prolonging service life, less investment, and no need for manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

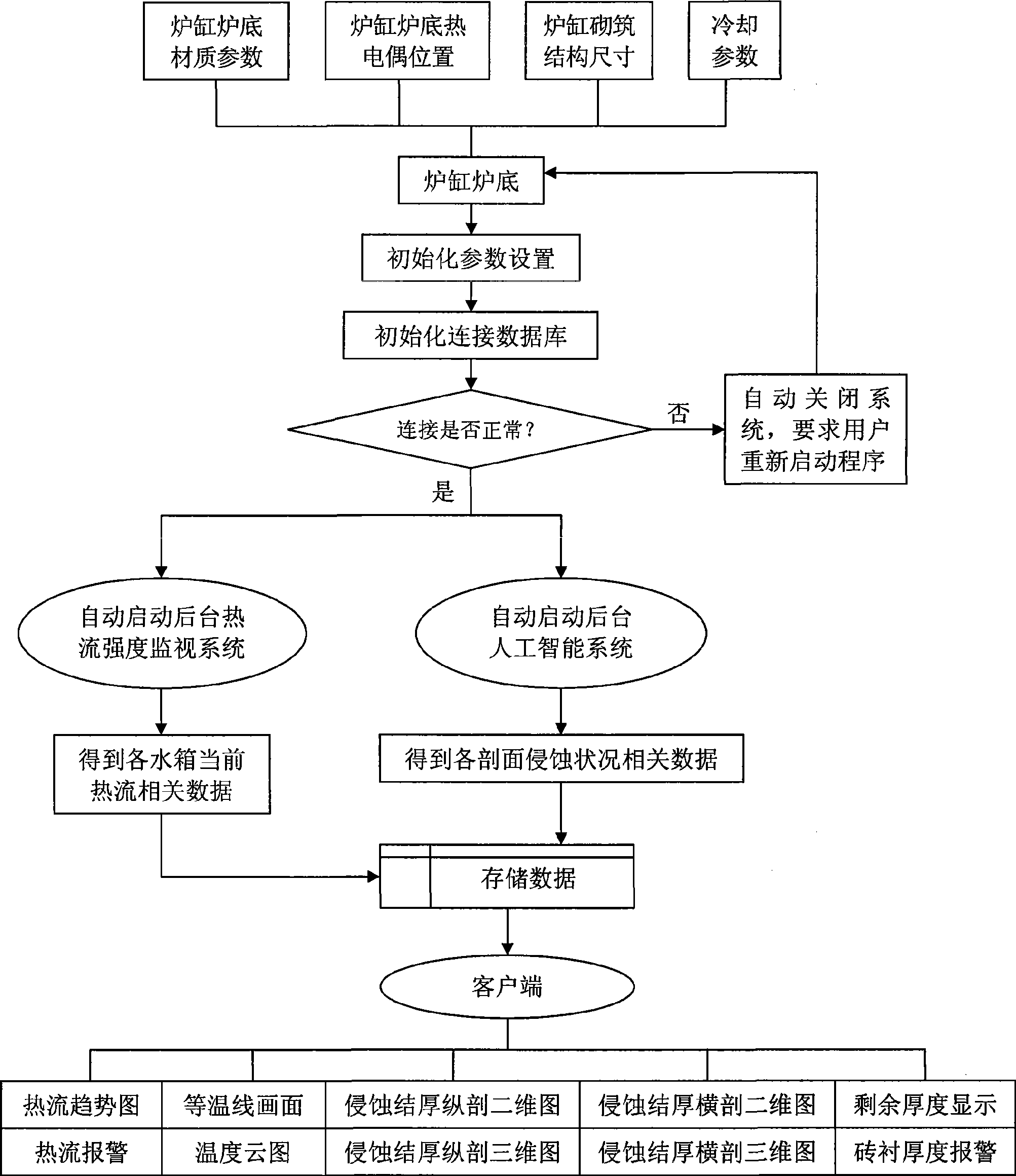

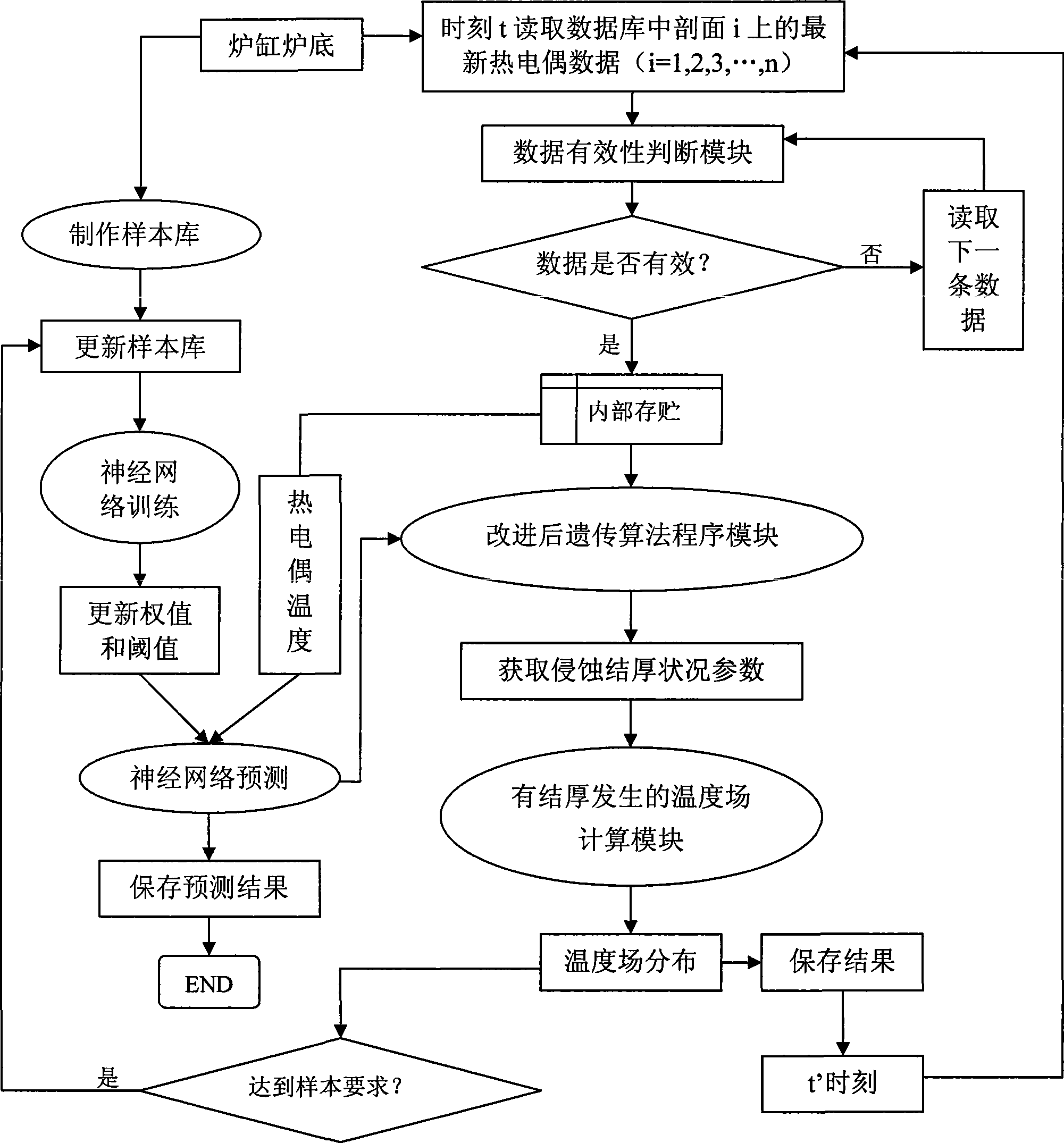

[0054] The thermocouple installed in the brick lining of the blast furnace hearth bottom and the detection point in the cooling device send data such as brick lining temperature, water temperature difference, flow rate, etc. to the primary system, and then communicate with the secondary system through Ethernet to send the data Server, the system automatically collects the data in the data server, and after the data validity is judged as the basic data, the temperature field model, the "inverse problem" model of the temperature field and the erosion knot thickness prediction model are respectively established to describe the hearth bottom area. Temperature field, simulated erosion and thickening conditions; establish a blast furnace hearth bottom erosion, junction thickness and heat flow monitoring, forecast and alarm system based on thermocoupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com