Method and apparatus to determine and control the carbon content of steel in a BOF vessel

a technology of carbon content and bof vessel, which is applied in the direction of optical radiation measurement, instruments, furnaces, etc., can solve the problems of large margin of error in the prediction of carbon levels, insufficient carbon predictions based on flame intensity measurements, and insufficient temperature calculations for more stringent present day needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

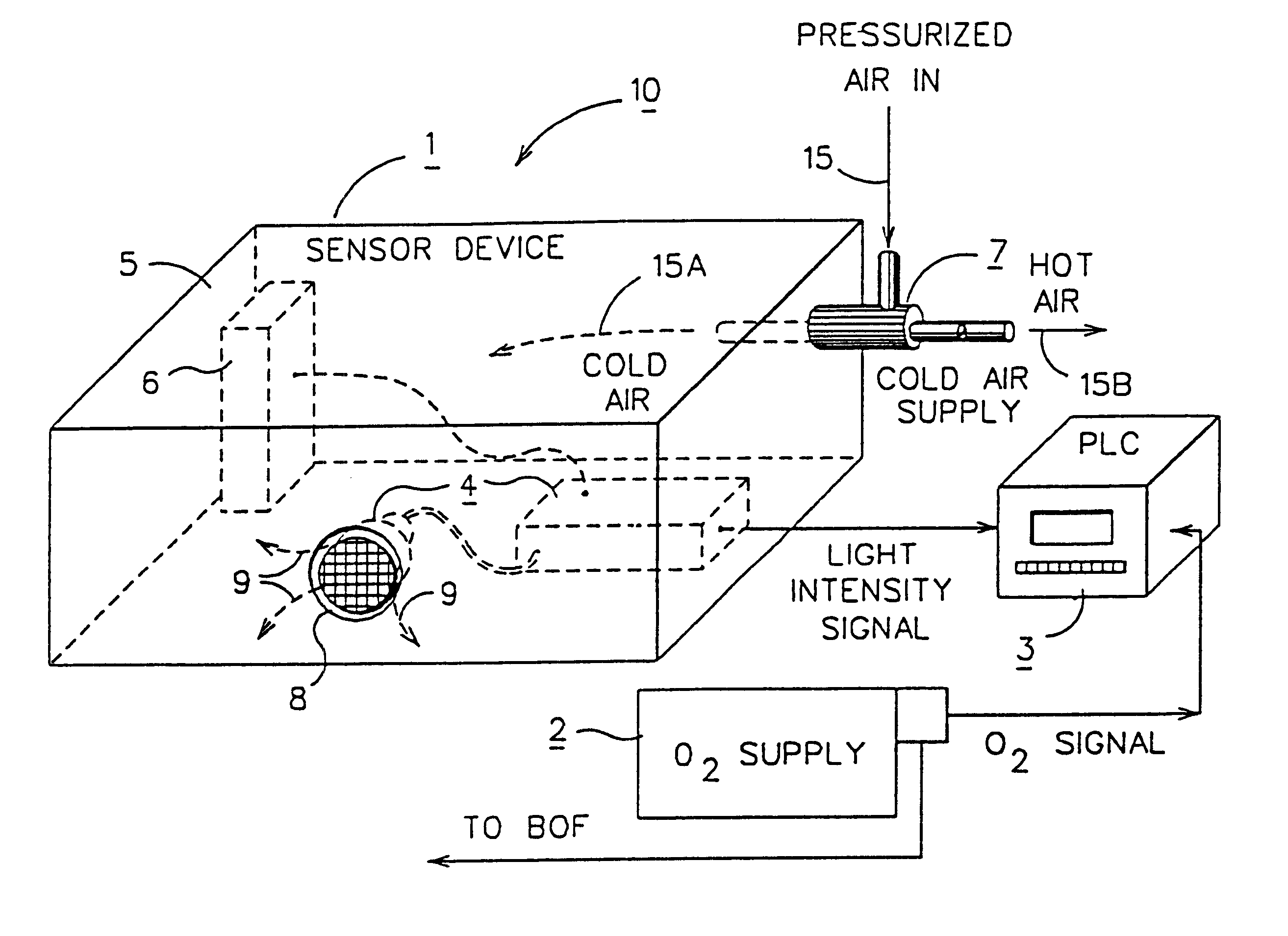

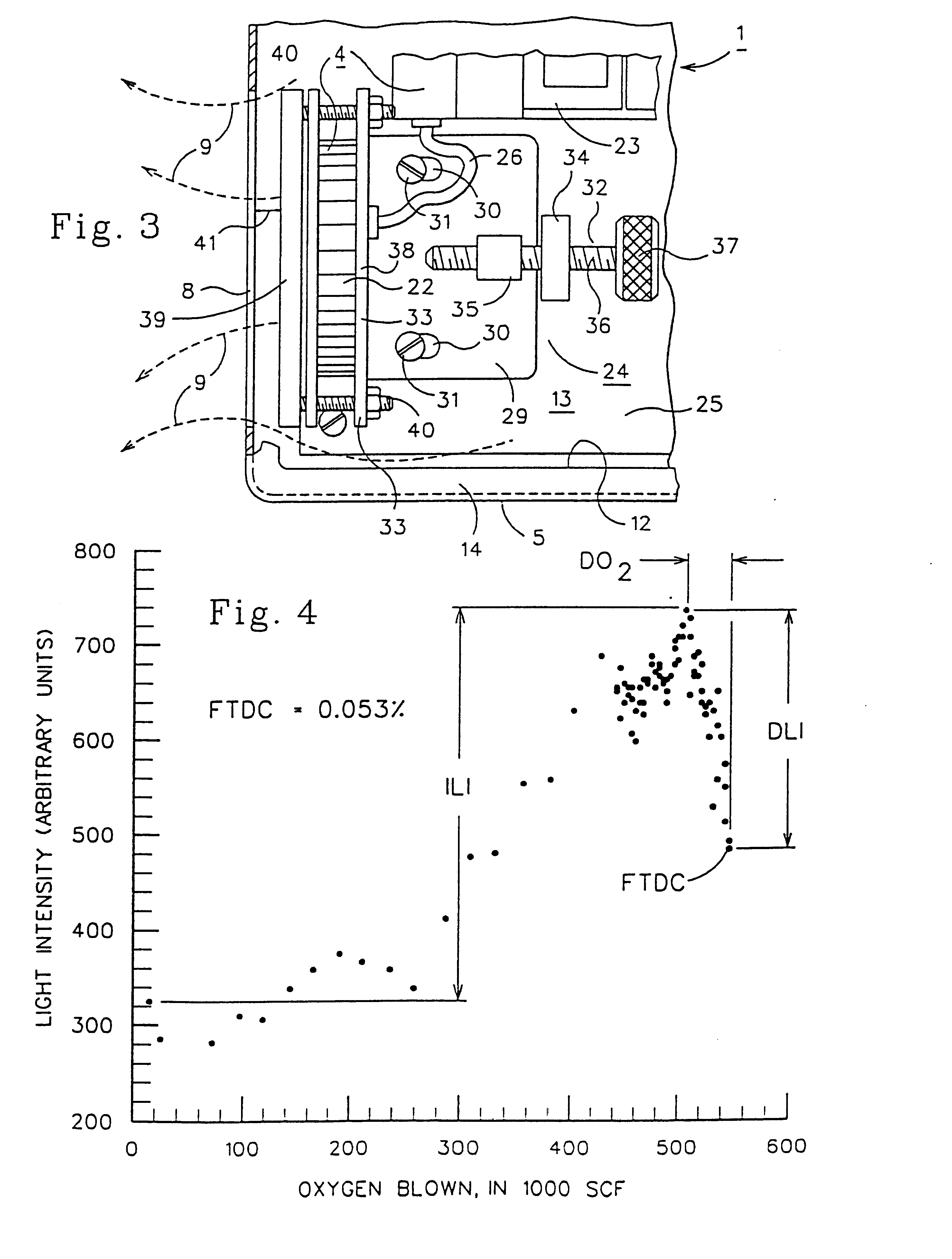

Referring to the drawings, FIG. 1 shows the preferred embodiment of the sensor system 10 for carrying out the steps of the method to determine in-blow % carbon content and FTDC levels of BOF heats. Throughout this specification, "in-blow carbon content" shall mean realtime carbon levels determined at any point during an oxygen blow, and "FTDC" shall mean First Turn Down Carbon determined at the end of the first oxygen blow into a BOF.

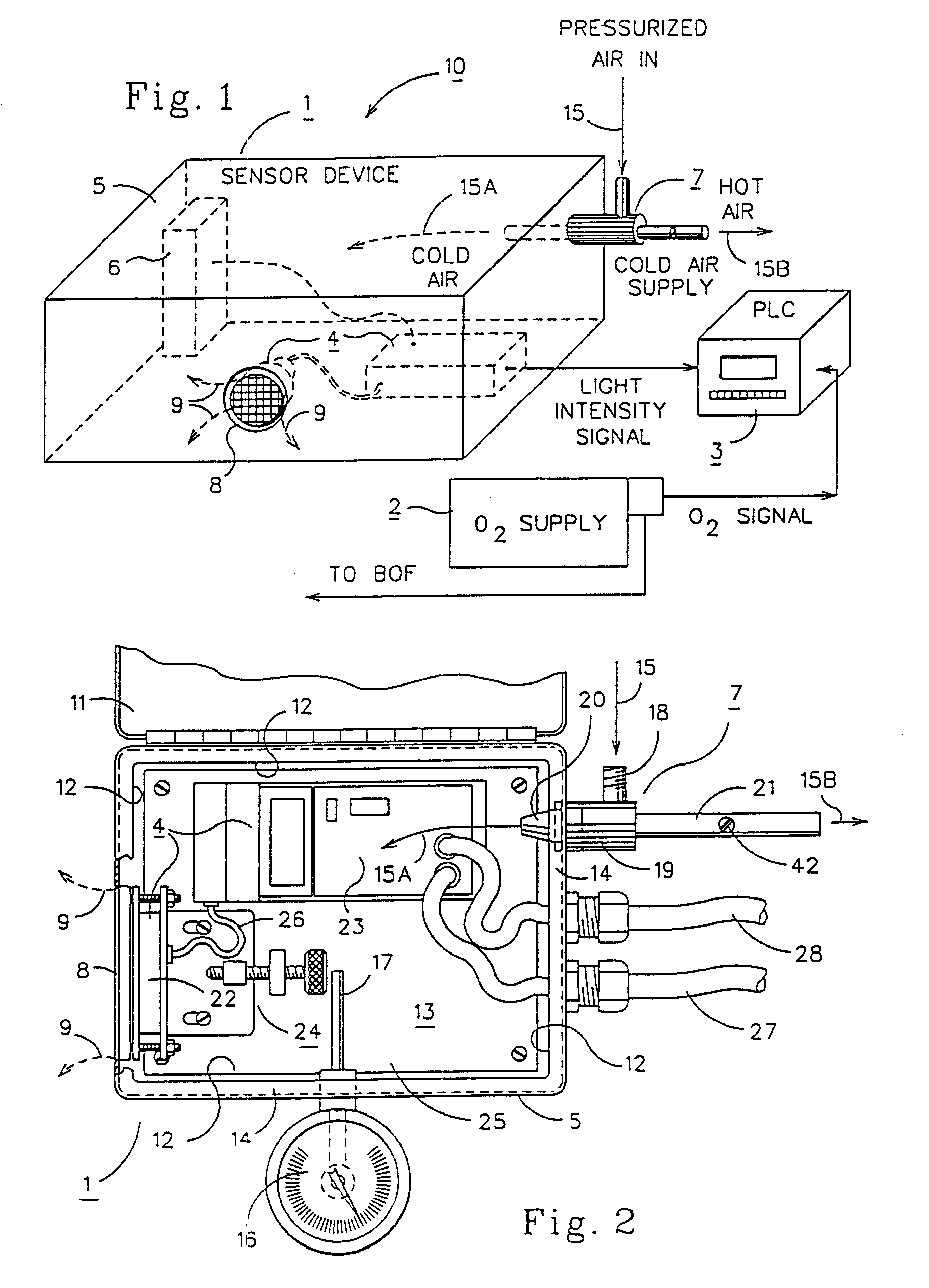

The system comprises a sensor device 1, an oxygen source 2, and a Programmable Logic Controller 3, (PLC). The sensor device 1 comprises a case or housing 5 to hold various electronic components of the sensor device including a light meter 4 having means to amplify light intensity signals to a level suitable for use in the PLC, a power supply 6, and a cold air supply 7 to prevent the hot steelmaking environment from overheating the sensor device. The sensor device further includes a sighting window 8 that extends through a wall of the case 5 to expose th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com