Novel mechanical scanning radar device for measuring shape of shaft furnace charge level

A blast furnace material surface and scanning radar technology, which is applied to the three-dimensional imaging of the near-field surface and the imaging field of the three-dimensional material surface in the blast furnace. problems, to achieve the effect of flexible selection, reduced difficulty, and extended working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, the features and functions of the embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

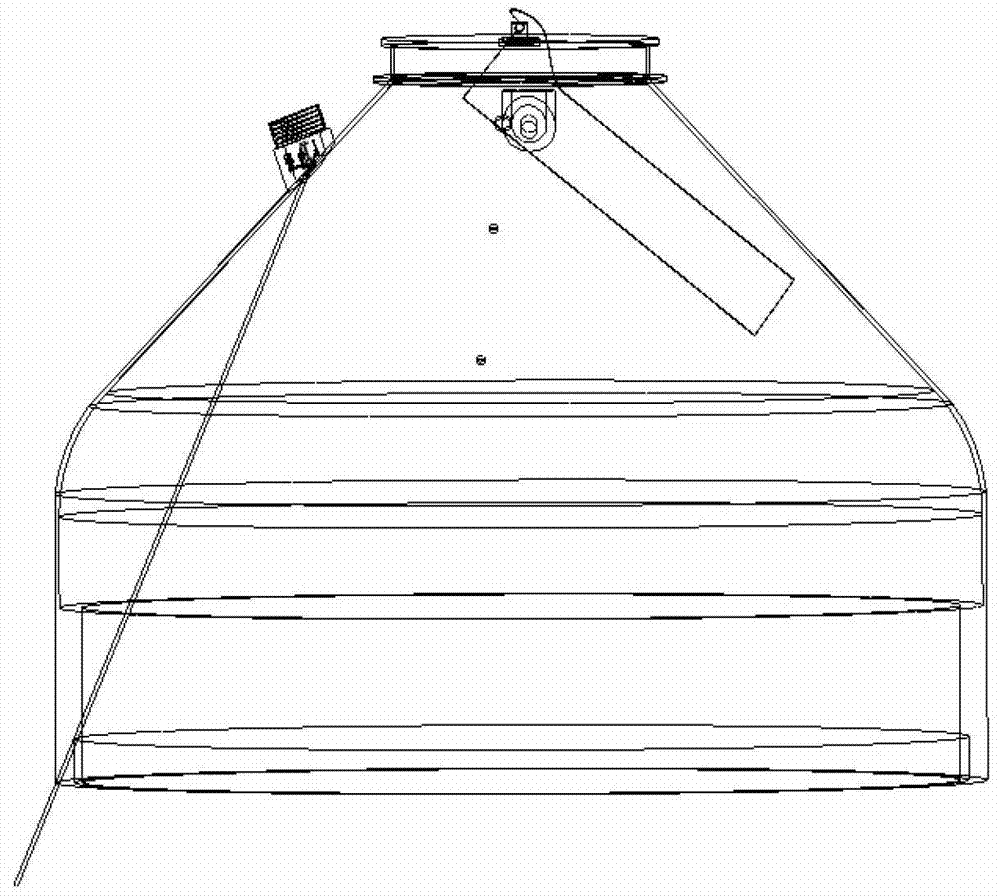

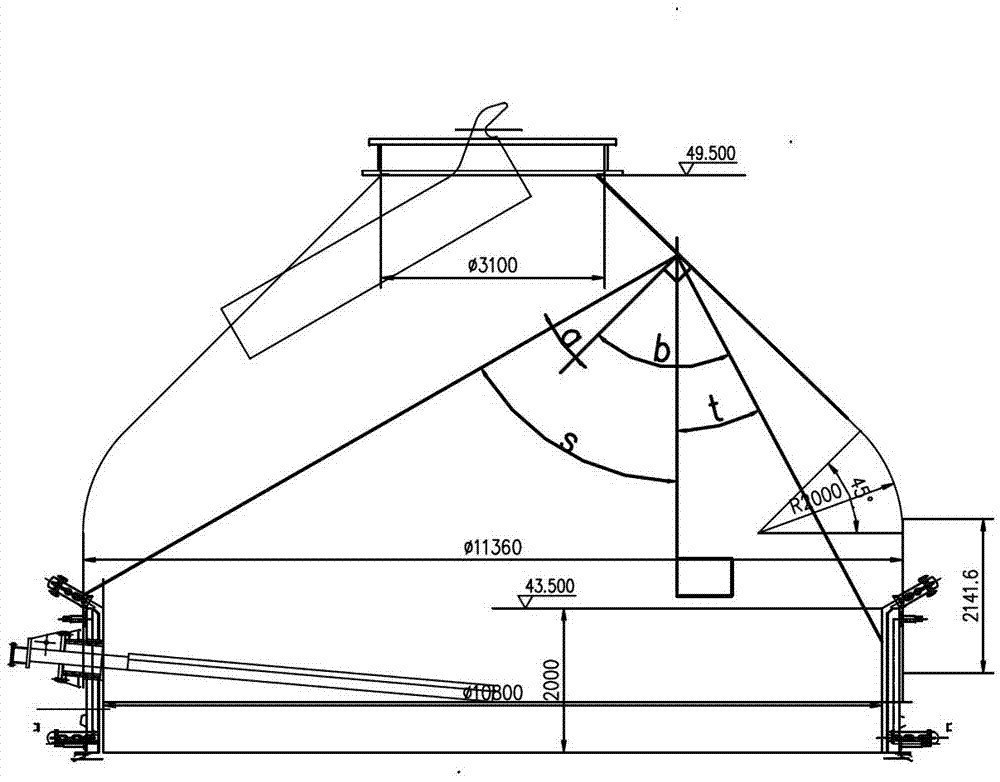

[0061] figure 1 and 3 The size drawing of blast furnace is adopted, and the proportion is shown according to the actual proportion of general blast furnace.

[0062] Such as figure 1 As shown, the radar is installed outside the blast furnace. Holes on the top of the furnace are opened according to the overall blast furnace installation drawing, and the pitch angle θ of the through holes with a diameter of Φ200-400m is calculated and determined according to site requirements. The system includes: radar installation tube, mechanical structure, field control box. The radar installation tube is welded on the furnace wall, and there is a water-cooling structure device inside the radar installation tube; the mechanical structure and high-temperature antenna are fixed in the radar protection tube, and the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com