Blast furnace molten iron silicon content feature analysis and prediction method

A blast furnace molten iron and characteristic analysis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as subcooling, furnace condition failure, overheating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

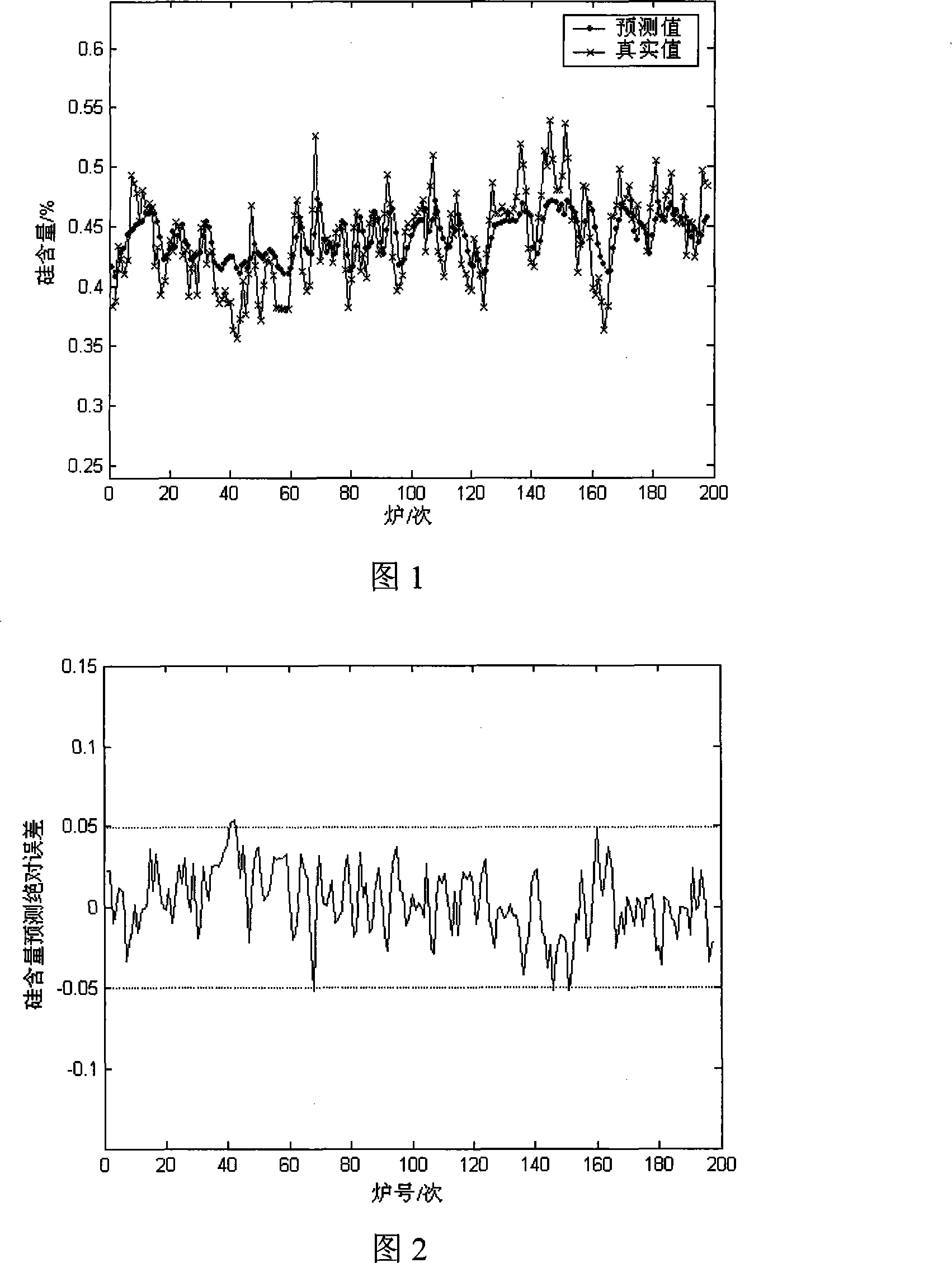

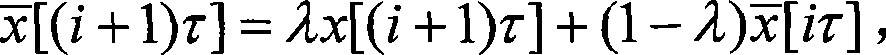

[0046] Aiming at the characteristics of high nonlinearity of the blast furnace ironmaking process and strong coupling between various blast furnace production parameters, the present invention combines the support vector machine algorithm and the independent component analysis algorithm in the blast furnace ironmaking production process, and establishes a blast furnace based on the support vector machine Furnace temperature forecast model. The invention has universal applicability to the prediction of the silicon content of molten iron in the blast furnace smelting process, improves the accuracy and hit rate of the prediction of the silicon content of the molten iron of the blast furnace, and provides technical guarantee for the smooth and reliable operation of the blast furnace.

[0047] The characteristic analysis and prediction method of silicon content in blast furnace hot metal includes the following steps:

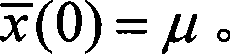

[0048] 1) Determine the model input variables for the predictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com