Method for forecasting silicon content in blast-furnace hot metal

A technology for blast furnace molten iron and silicon content, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as unsatisfactory results

Active Publication Date: 2011-04-27

ANGANG STEEL CO LTD

View PDF3 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

result in unfavorable predictions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0069] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

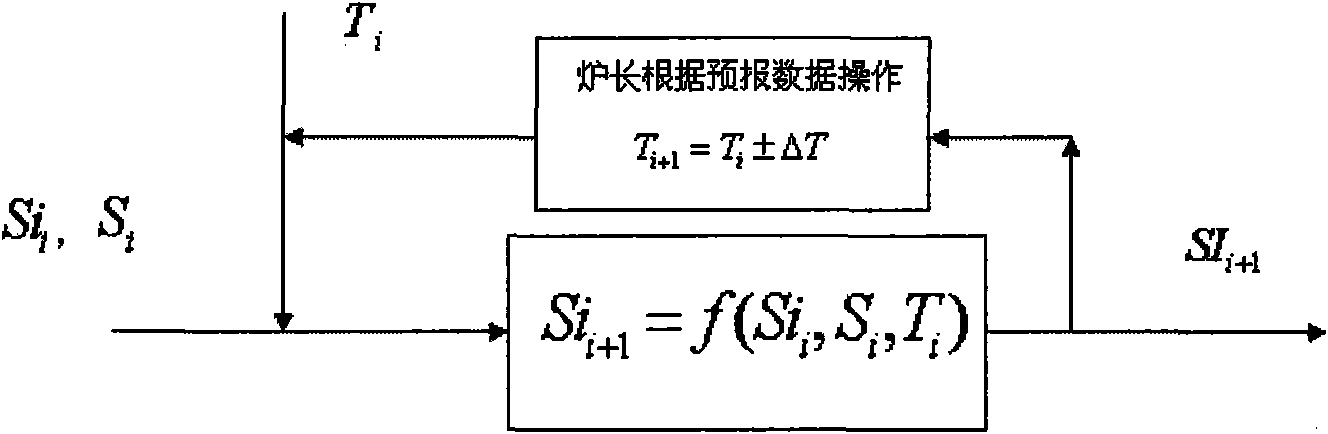

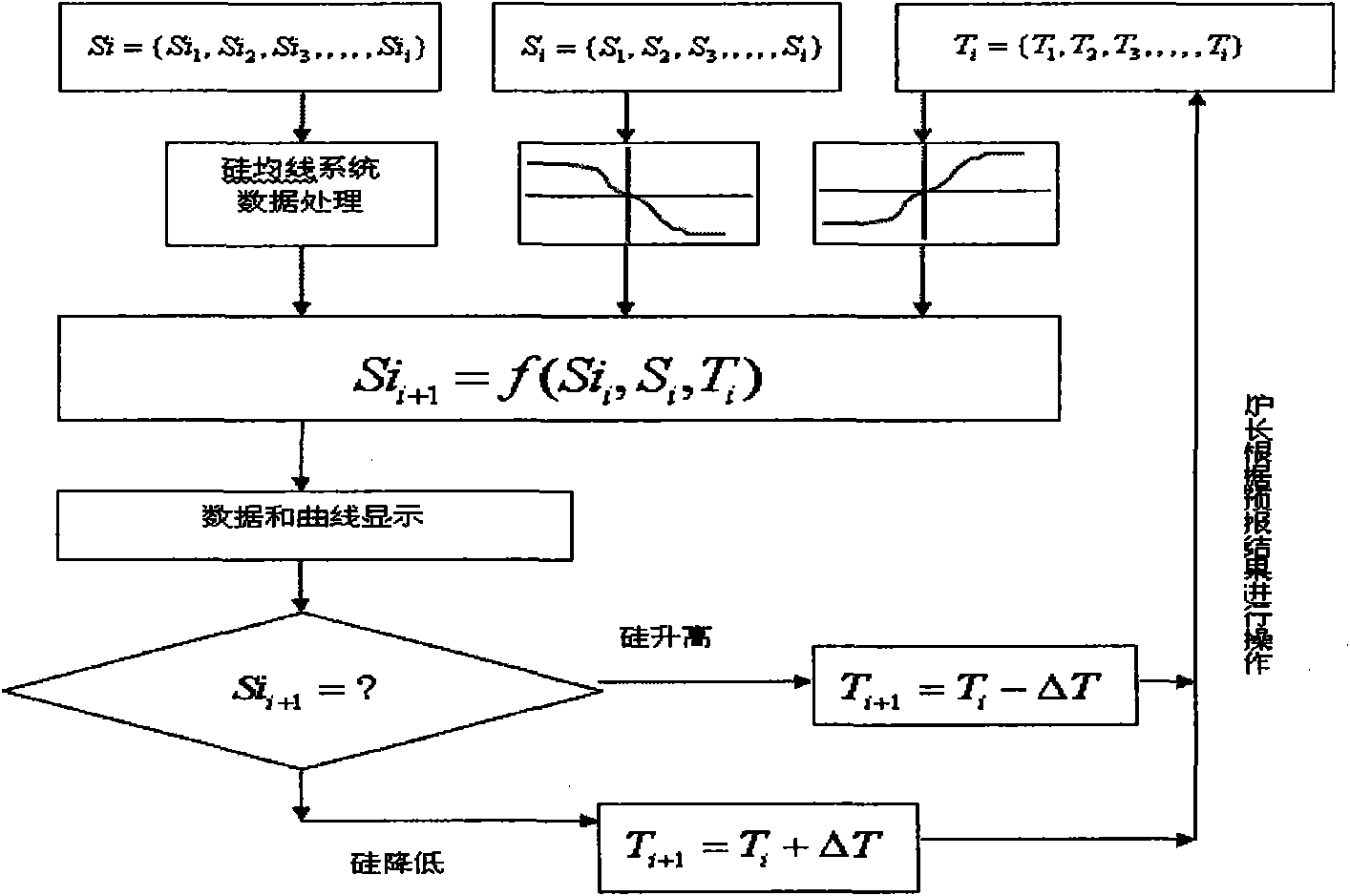

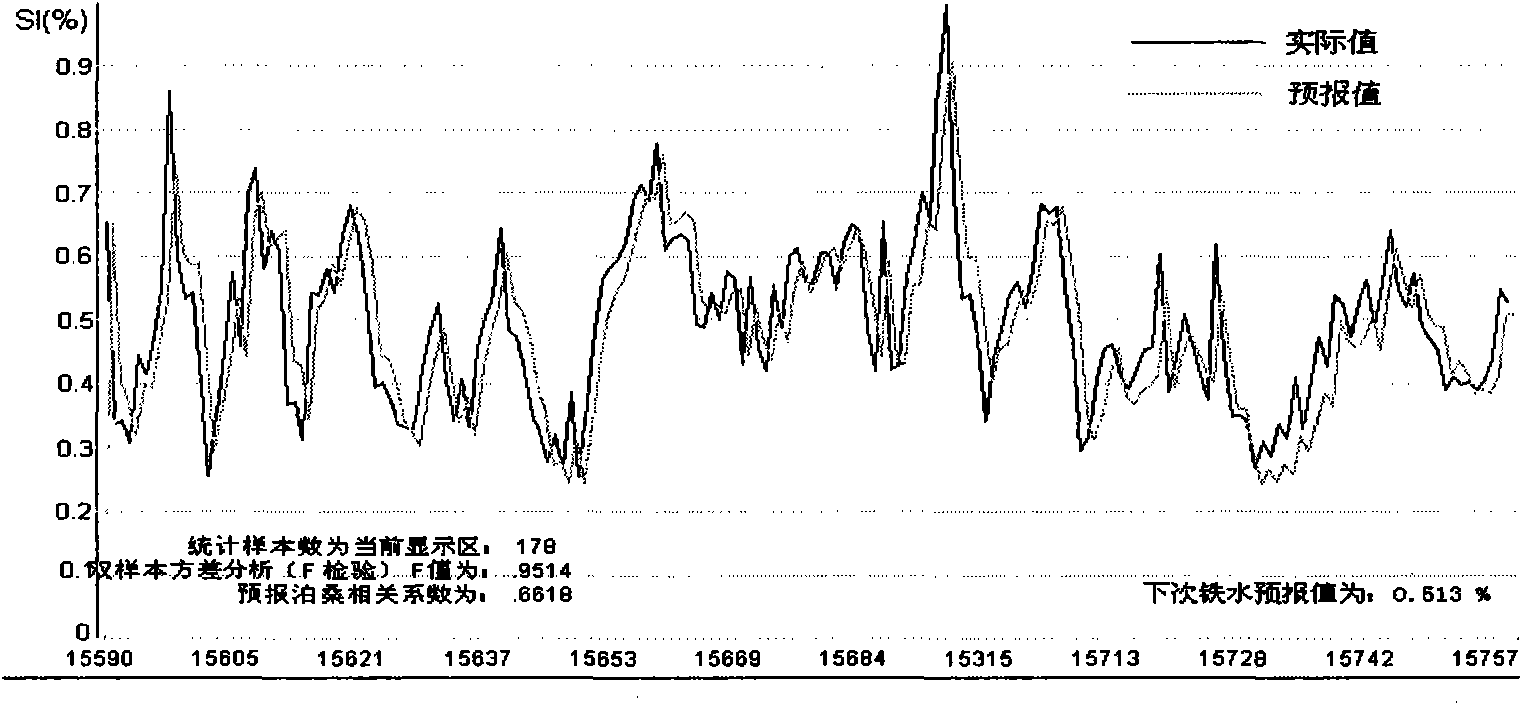

The invention discloses a method for forecasting the silicon content in blast-furnace hot metal, which comprises the steps of data parameter selection, pre-processing, prediction algorithm, result output and operation guidance. In the step of data parameter selection, five parameters such as short-term mean value of the silicon content, medium-term mean value of the silicon content, long-term mean value of the silicon content, tuyere theoretical combustion temperature corresponding to the previous hot metal and sulfur content in the previous hot metal are adopted, and the silicon content is predicted through the prediction algorithm. When the furnace condition fluctuation is small, an average line system is mainly used; and when the furnace condition fluctuation is large, the tuyere theoretical combustion temperature and the sulfur content in the previous hot metal are automatically added. In the invention, less data parameters are adopted, better forecasting precision is obtained andthe forecasting correctness of the silicon content in the blast-furnace hot metal is improved.

Description

technical field [0001] The invention belongs to the technical field of automatic detection, and in particular relates to a method for predicting the silicon content of molten iron in the blast furnace during the blast furnace smelting process. Background technique [0002] The blast furnace is a closed high-temperature reaction vessel. The production process is accompanied by complex physical and chemical reactions and heat and mass transfer processes, and its internal changes cannot be directly detected. Generally, the process parameters are used to indirectly judge the working status of the blast furnace. In the smelting process, furnace temperature control is the most important link in blast furnace operation. If the furnace temperature fluctuates, the formation of "overheating" or "overcooling" will directly affect the smoothness of the furnace condition. Experience shows that there is a positive correlation between the silicon content of molten iron and the furnace te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21B5/00G06F17/10

Inventor 李连成车玉满孙波孙鹏郭天永

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com