Forecasting method of content of sulfur in blast-furnace molten iron

A technology for blast furnace molten iron and silicon content in molten iron, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as ineffective prediction of sulfur content in molten iron, reduced hit rate, and high hit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

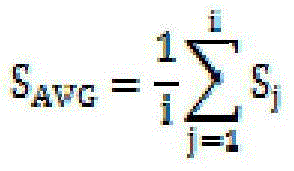

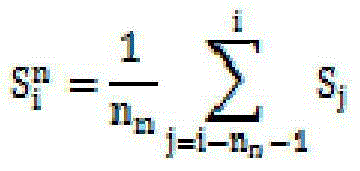

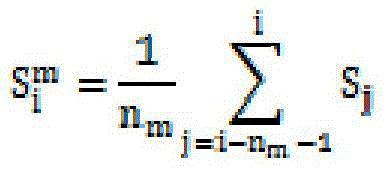

[0063] The method for predicting the sulfur content of blast furnace molten iron in the present invention is mainly based on the short-term average value of sulfur content, the medium-term average value of sulfur content, the long-term average value of sulfur content, the slag basicity corresponding to the previous molten iron, the silicon content of the previous molten iron, the S content of coke entering the furnace, the Furnace pulverized coal S content is used as the input variable of molten iron sulfur prediction, using the chemical reaction process of blast furnace to form molten iron, combined with RBF neural network, to predict the sulfur content of the next molten iron, relying on the average system when the furnace condition fluctuates When it is large, the slag basicity and the silicon content of the previous molten iron are automatically added to obtain better prediction accuracy with fewer independent variables and improve the prediction hit rate of sulfur content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com