Variable selection and forecast method of silicon content in molten iron of blast furnace

A blast furnace hot metal, variable selection technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as noise, silicon content prediction accuracy obstacles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

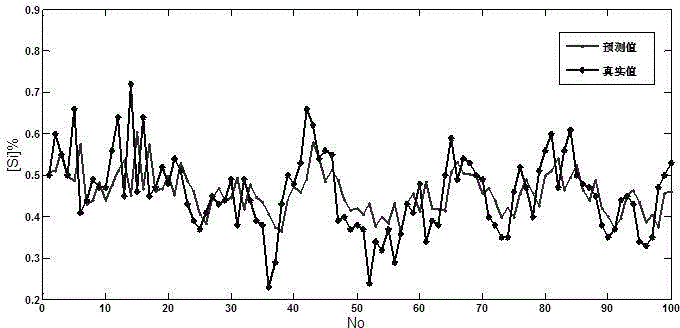

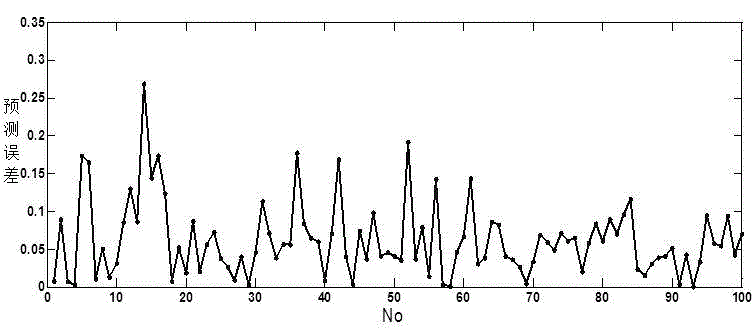

[0068] In order to verify the effectiveness of the proposed method of the present invention, a 2500m 3 The actual production data of the blast furnace was used to carry out the application experiment of the prediction of the silicon content of molten iron. Selection includes furnace top pressure, furnace top temperature, material velocity, CO in furnace top gas, CO 2 and the silicon content of the previous furnace are used as the input variables of the silicon content prediction model. For the sampling data of all variables used in the process of model training and model prediction, the measured average value in units of molten iron furnaces is used as the sampling and forecasting period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com