Dynamic stereo monitoring system and detection method for charge surface shape in blast furnace

A blast furnace material level and monitoring system technology, applied in the direction of inspection devices, etc., can solve problems such as online real-time monitoring, and achieve the effect of strong echo effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

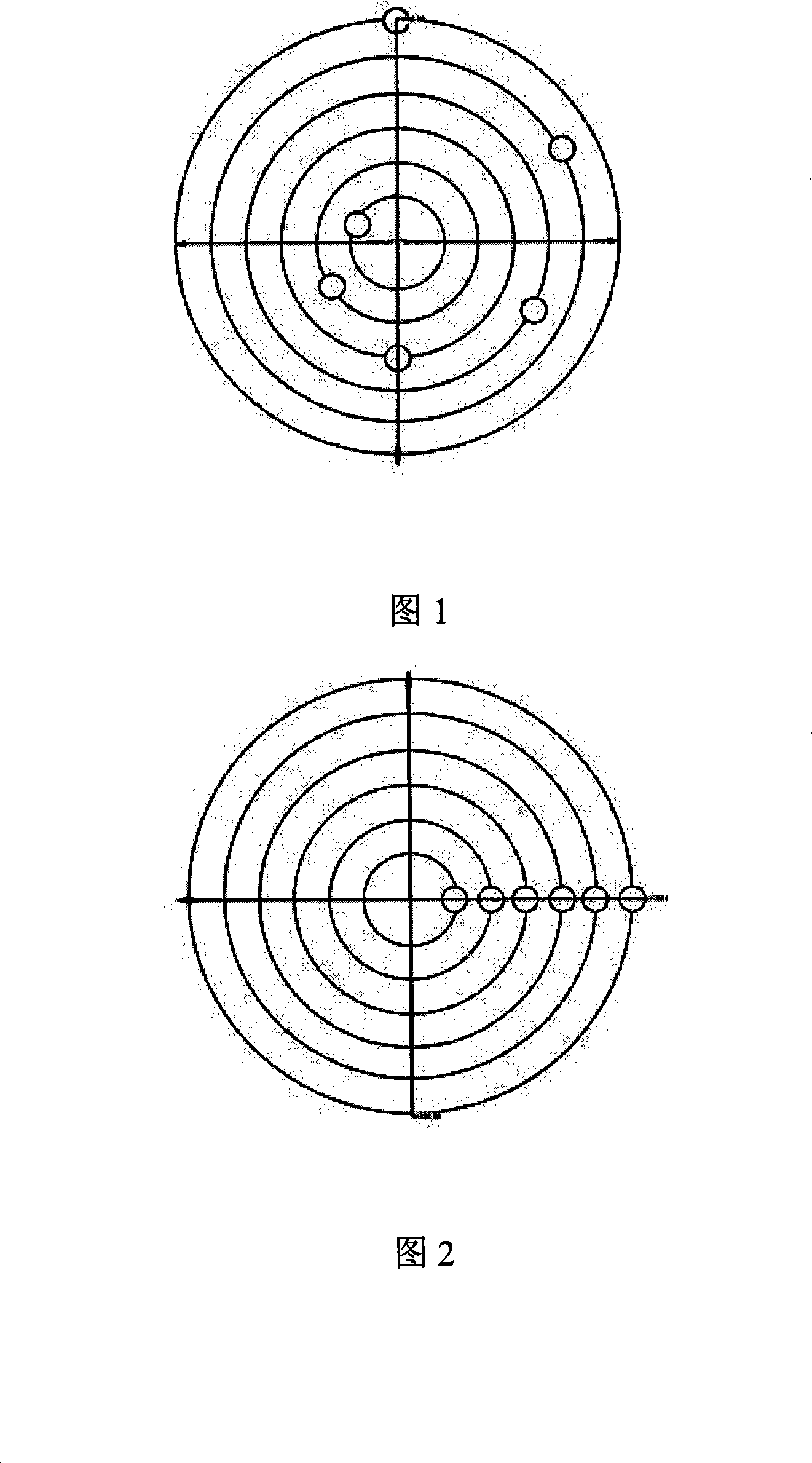

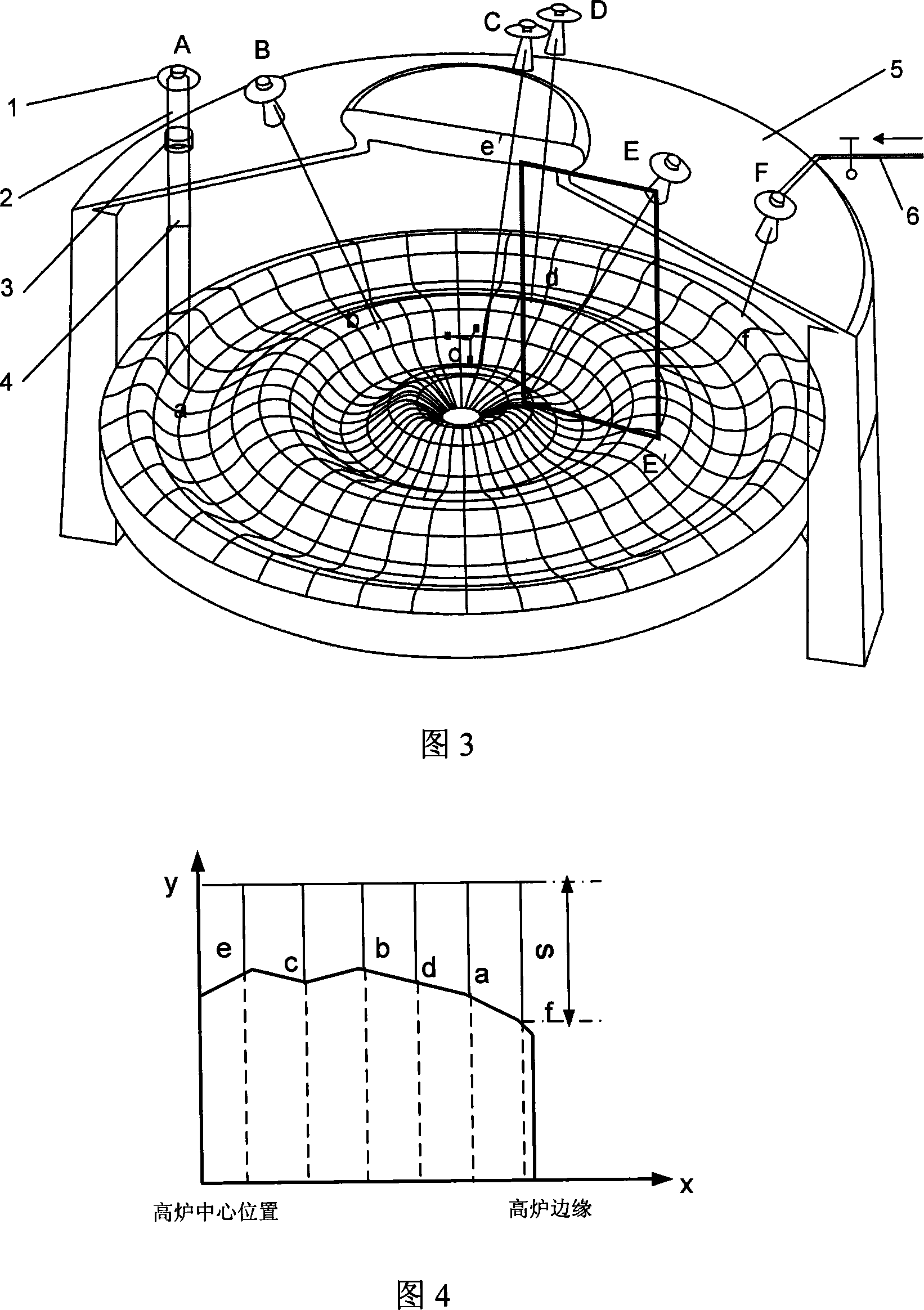

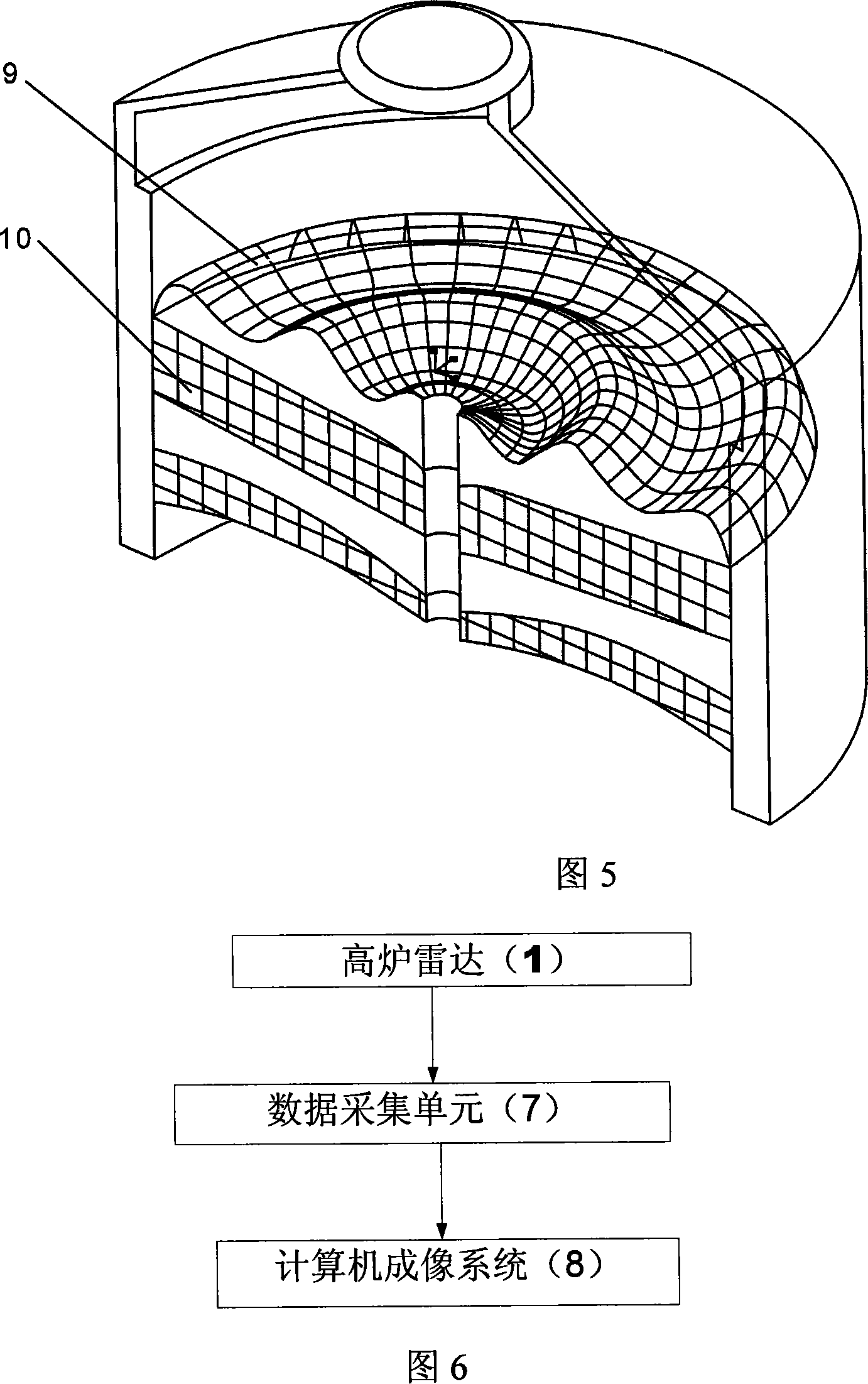

[0050]1 to 6 are specific embodiments of the present invention. As shown in Figure 3. A, B, C, D, E, F are six blast furnace charge level radars, a, b, c, d, e, f are A, B, C, D, E, F corresponding to the six radars Measuring point. Among them, the radars B, C, D, E, and F of the measuring points b, c, d, e, and f are installed obliquely, and the radar A is installed vertically. The vertically installed radar A can reach the measuring point according to its installation position and the radar. The distance directly obtains the effective measured height value.

[0051] For the radar installed obliquely, take the E-point radar as an example, where Ee is the oblique measurement path of the radar E, and ee′ is the vertical distance from the oblique radar E to the material level measurement point e contour. After the distance Ee, according to the Pythagorean theorem and the position and angle of the radar installation, the accurate radial position Ee′ of the corresponding measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com