Manufacturing method of curved frequency selective surface array

A technology of frequency selective surface and fabrication method, applied in the direction of electrical components, antennas, etc., can solve the problem of inability to fabricate a patch-type FSS curved surface unit array, etc., and achieve the effect of strong versatility and good matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

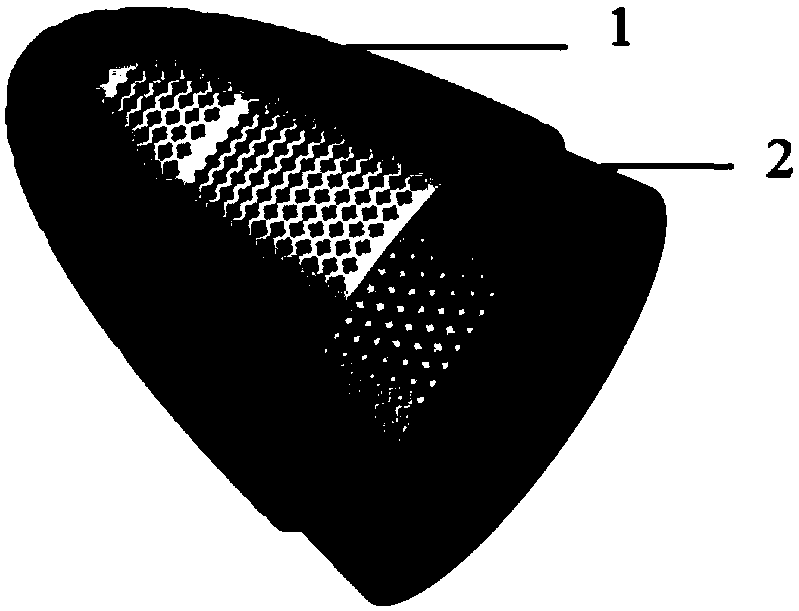

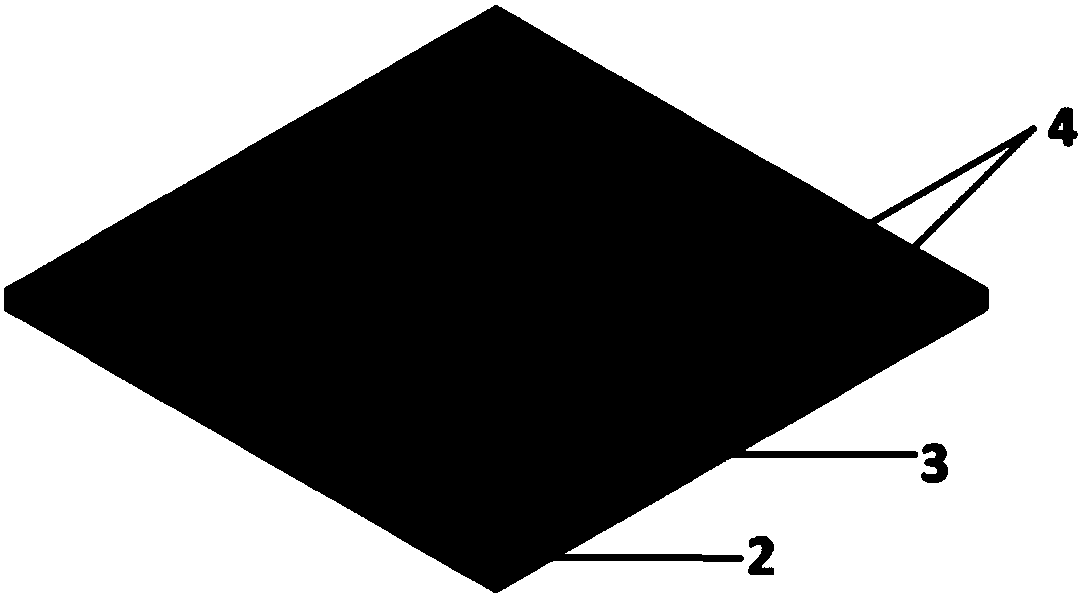

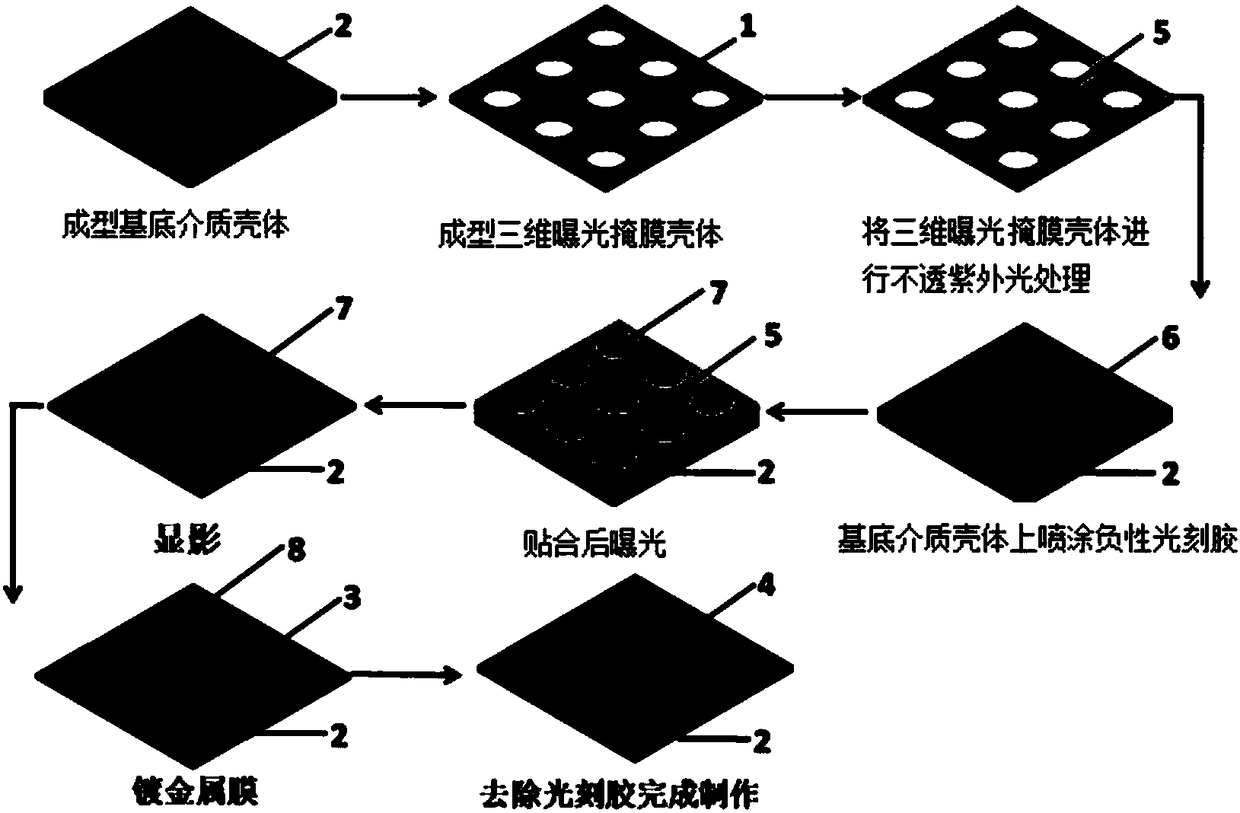

[0056] In this embodiment, a circular opening type (referred to as round hole) curved surface FSS array is formed on the above-mentioned base dielectric shell 2, such as figure 2 As shown, a metal layer 3 is attached to the base dielectric shell 2, and an array of circular hole units 4 is formed on the metal layer 3. The main manufacturing process is as follows image 3 As shown, it specifically includes the following steps:

[0057] (1) The three-dimensional exposure mask housing 1 is modeled with Solidworks software, and the three-dimensional exposure mask housing 1 is distributed with hollow circular holes, the size of which is consistent with the size of the finally formed circular hole unit 4; the three-dimensional exposure mask The shell 1 and the outer surface of the base dielectric shell 2 are shaped, and the thickness of the three-dimensional exposure mask shell 1 in this embodiment is 0.5mm;

[0058] (2) The photosensitive resin is used as the raw material, and the...

Embodiment 2

[0066] In this embodiment, a circular patch type (circular patch for short) FSS array is formed on the above-mentioned base dielectric shell 2, as Figure 4 As shown, an array of circular patch units 9 is prepared on the substrate dielectric shell 2, and the main process flow is as follows Figure 5 As shown, it specifically includes the following steps:

[0067] (1) Modeling the three-dimensional exposure mask housing 1 with Solidworks software, the three-dimensional exposure mask housing 1 is distributed with hollow circular holes, and the size of the circular holes is consistent with the size of the finally formed circular patch unit 9; the three-dimensional exposure mask The outer surface of the film case 1 and the base dielectric case 2 is shaped, and the thickness of the three-dimensional exposure mask case 1 in this embodiment is 0.5 mm;

[0068] (2) The photosensitive resin is used as the raw material, and the mask shell is printed by the stereolithography (SLA) proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com