A kind of ultra-low density aluminum-lithium alloy and preparation method thereof

An aluminum-lithium alloy, ultra-low density technology, applied in the field of aluminum alloys, can solve problems such as insufficient plasticity and toughness, achieve the effects of reducing oxidation slag inclusions, ensuring yield, and improving performance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

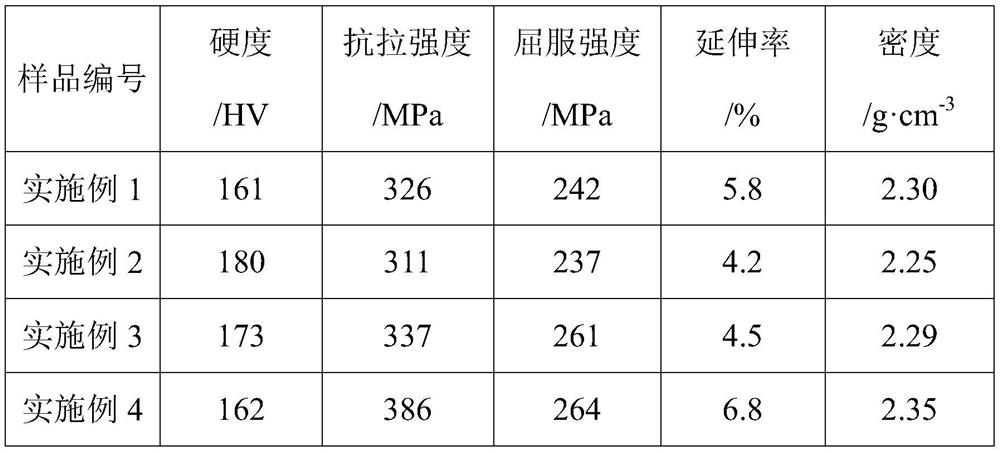

Examples

Embodiment 1

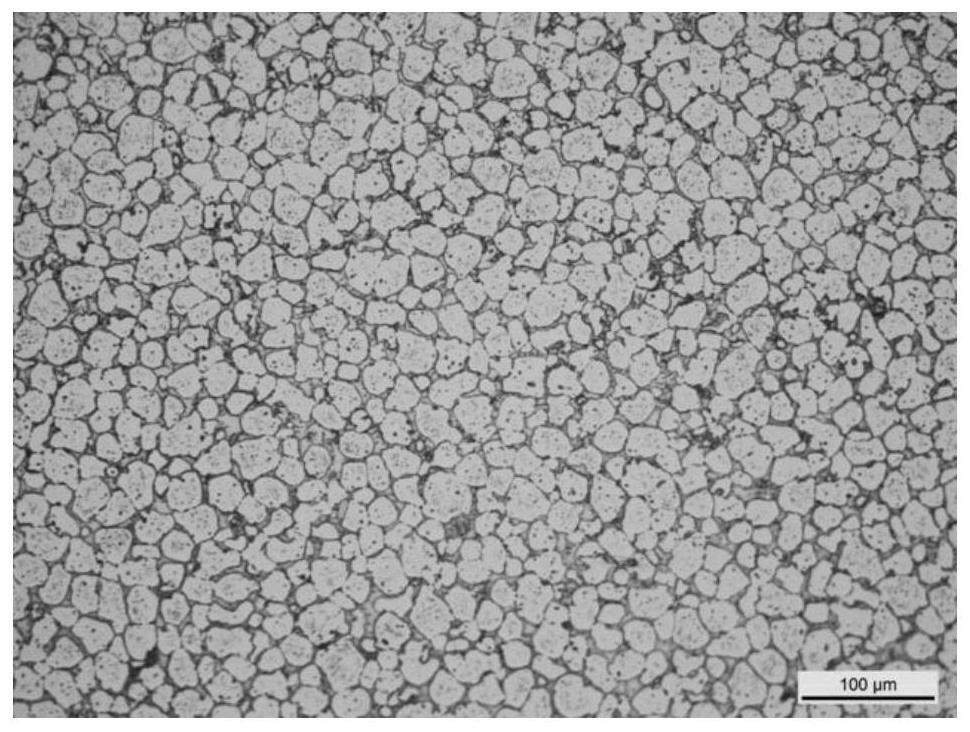

[0030] like figure 1 As shown, an ultra-low density aluminum-lithium alloy is composed of the following mass percentage components: magnesium: 9.0%, lithium: 2.1%, beryllium: 0.01%, manganese: 0.1%, zinc: 0.1%, rare earth: 0.05%, The balance is aluminum.

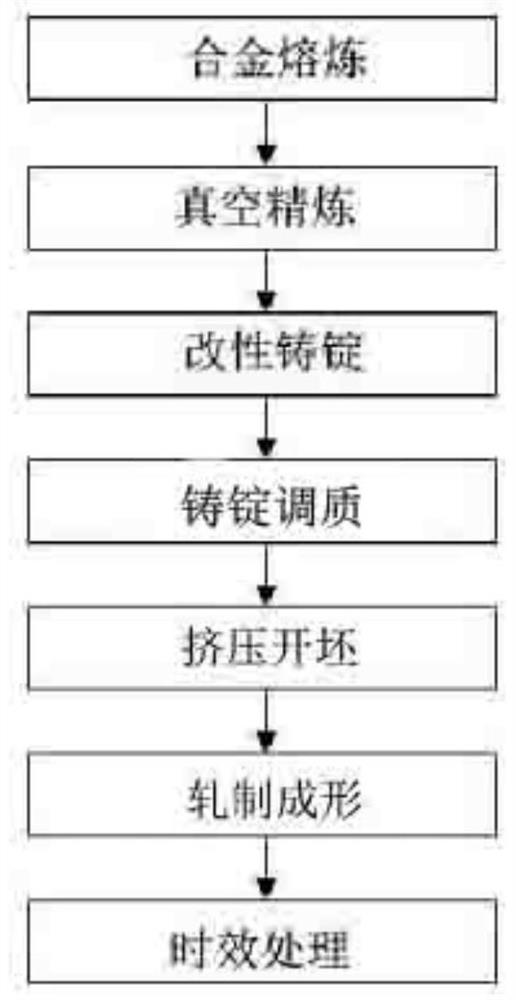

[0031] like figure 2 Shown, a kind of preparation method of ultra-low density aluminum-lithium alloy comprises the following steps:

[0032] S1, alloy smelting, mixing all raw materials, and preheating to 100°C at a constant speed, at the same time, decompressing the melting furnace, heating up and preheating and feeding argon, and making the internal vacuum of the melting furnace reach to 2Pa, the temperature is constant at 300°C, and finally the preheated raw material mixture is added to the vacuum induction melting furnace, and the temperature is raised to 740°C at a constant speed for heat preservation and melting to obtain molten metal;

[0033] S2, vacuum refining, after completing step S1, mechanically stir the ob...

Embodiment 2

[0043] like figure 1As shown, an ultra-low density aluminum-lithium alloy is composed of the following mass percentage components: magnesium: 12.5%, lithium: 3.5%, beryllium: 0.1%, manganese: 0.5%, zinc: 0.5%, rare earth: 0.5%, The balance is aluminum.

[0044] Such as figure 2 Shown, a kind of preparation method of ultra-low density aluminum-lithium alloy comprises the following steps:

[0045] S1, alloy smelting, mixing all raw materials, and preheating to 260°C at a constant speed, at the same time, decompressing the melting furnace, heating up and preheating and feeding argon, and making the internal vacuum of the melting furnace reach to 2Pa, the temperature is constant at 560°C, and finally the preheated raw material mixture is added to the vacuum induction melting furnace, and the temperature is raised to 780°C at a constant speed for heat preservation and melting to obtain molten metal;

[0046] S2, vacuum refining, after completing step S1, the obtained molten met...

Embodiment 3

[0056] Such as figure 1 As shown, an ultra-low density aluminum-lithium alloy is composed of the following mass percentage components: magnesium: 11%, lithium: 2.8%, beryllium: 0.05%, manganese: 0.3%, zinc: 0.35%, rare earth: 0.2%, The balance is aluminum.

[0057] Such as figure 2 Shown, a kind of preparation method of ultra-low density aluminum-lithium alloy comprises the following steps:

[0058] S1, alloy smelting, mixing all raw materials, and preheating to 160°C at a constant speed, at the same time, decompressing the melting furnace, heating up and preheating and feeding argon, and making the internal vacuum of the melting furnace reach to 2Pa, the temperature is constant at 460°C, and finally the preheated raw material mixture is added to the vacuum induction melting furnace, and the temperature is raised to 750°C at a constant speed for heat preservation and melting to obtain molten metal;

[0059] S2, vacuum refining, after completing the step S1, the obtained mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com